The Rising Demand for Flexible Circuit Boards in German Automation

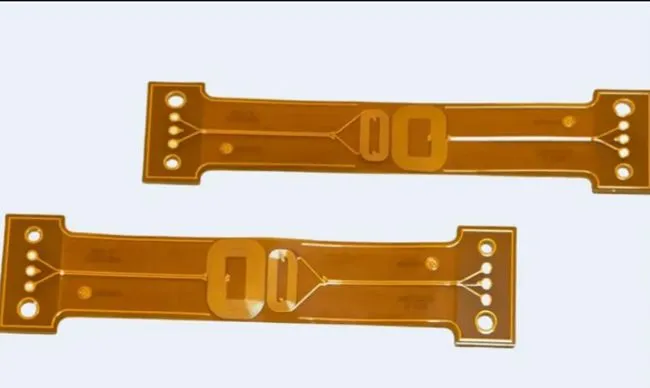

The German computerization industry has seen a critical surge in the selection of adaptable circuit sheets. This slant is driven by the expanding require for compact, lightweight, and flexible electronic components in different computerization applications. Adaptable PCBs offer one of a kind preferences over their inflexible partners, making them vital in cutting edge mechanization systems. Flexible Circuit Board give surprising plan adaptability, permitting engineers to make imaginative arrangements for complex mechanization challenges.

These sheets can be bowed, collapsed, or formed to fit into tight spaces, empowering the advancement of more compact and effective computerized frameworks. This characteristic is especially profitable in businesses where space optimization is vital, such as car fabricating, mechanical autonomy, and mechanical control systems. Moreover, the solidness and unwavering quality of adaptable PCBs contribute to their developing notoriety in German robotization. These sheets can withstand vibrations, extraordinary temperatures, and rehashed flexing without compromising execution. This versatility is fundamental in cruel mechanical situations where electronic components must keep up usefulness beneath challenging conditions.

Advantages of Flexible Circuit Boards in Automation Applications

The integration of flexible circuit boards in automation systems offers numerous benefits that align with the high standards of German engineering:

- Weight Reduction: Flexible PCBs are significantly lighter than traditional rigid boards, contributing to overall weight reduction in automated systems. This is particularly advantageous in applications where weight savings translate to improved energy efficiency and performance.

- Enhanced Reliability: The ability to withstand mechanical stress and vibrations makes flexible PCBs highly reliable, reducing the risk of failures in critical automation components.

- Improved Heat Dissipation: The thin profile of flexible circuit boards allows for better heat dissipation, which is crucial in maintaining the longevity and performance of automation equipment.

- Design Versatility: Flexible PCBs can be designed to fit complex three-dimensional spaces, enabling innovative solutions in automation system layouts and configurations.

- Cost-Effective Wiring Solutions: By replacing bulky wire harnesses with flexible PCBs, manufacturers can achieve more efficient and cost-effective wiring solutions in automated systems.

As German mechanization proceeds to advance towards more modern and compact plans, the request for high-quality adaptable circuit sheets is anticipated to develop. This slant underscores the significance of joining forces with experienced and dependable adaptable PCB producers who can meet the rigid prerequisites of German mechanization industries.

Key Factors in Selecting a Flexible PCB Manufacturer for German Automation Projects

Choosing the right flexible PCB manufacturer is crucial for the success of German automation projects. Several key factors should be considered to ensure that the selected manufacturer can meet the high standards and specific requirements of the industry:

Technical Expertise and Manufacturing Capabilities

A top-tier adaptable PCB producer must have progressed specialized information and state-of-the-art fabricating capabilities. This incorporates mastery in dealing with different adaptable materials, executing complex plans, and utilizing cutting-edge generation procedures. The capacity to create multi-layer adaptable PCBs and consolidate progressed highlights such as microvias and HDI (High-Density Interconnect) innovation is fundamental for assembly the advanced necessities of German mechanization systems.

Ring PCB, for occurrence, gloats broad encounter in fabricating Flexible Circuit Board with up to 48 layers, illustrating their capability to handle complex plans. Their progressed fabricating forms guarantee the generation of high-quality, dependable adaptable PCBs that can withstand the requesting conditions of computerization environments.

Quality Assurance and Certifications

Rigorous quality control measures and adherence to universal measures are non-negotiable when selecting a adaptable PCB producer for German computerization ventures. See for producers that have actualized comprehensive quality administration frameworks and hold significant certifications such as ISO 9001, ISO 14001, and UL certification. Ring PCB's commitment to quality is apparent in their rigid quality control forms, which incorporate X-ray review, AOI (Mechanized Optical Review) testing, and 100% utilitarian approval. These measures guarantee that each adaptable PCB meets the most noteworthy benchmarks of quality and unwavering quality some time recently coming to the client.

Design for Manufacturability (DFM) and Design for Assembly (DFA) Expertise

The capacity to optimize plans for manufacturability and get together is pivotal in the generation of adaptable PCBs for computerization applications. A producer with solid DFM and DFA capabilities can offer assistance recognize potential issues early in the plan stage, diminishing generation dangers and optimizing costs. Ring PCB's master designing group exceeds expectations in DFM and DFA optimization, working closely with clients to refine plans, decrease potential dangers, and minimize BOM (Charge of Materials) costs. This collaborative approach guarantees that the last item not as it were meets execution necessities but is too optimized for proficient generation and assembly.

Customisation and Flexibility

German computerization ventures frequently require custom-made arrangements to meet particular application necessities. A adaptable PCB producer ought to be able to offer customization alternatives and illustrate adaptability in adjusting to special venture needs. This incorporates the capacity to work with a assortment of materials, thicknesses, and circuit configurations. Ring PCB's involvement in serving differing businesses, counting car, aviation, and therapeutic divisions, exhibits their capacity to adjust to different client prerequisites. Their customization capabilities guarantee that each adaptable PCB is optimized for its planning application in German computerization systems.

Supply Chain Management and Component Sourcing

Efficient supply chain administration and dependable component sourcing are basic components in guaranteeing opportune generation and conveyance of adaptable PCBs. A producer with solid connections with component providers and a strong supply chain arrange can superior explore potential challenges and keep up reliable generation schedules. Ring PCB offers comprehensive component sourcing administrations as portion of their one-stop turnkey arrangements. This coordinates approach streamlines the generation handle, lessening lead times and guaranteeing the accessibility of high-quality components for adaptable PCB assembly.

Ring PCB: A Leading Flexible PCB Manufacturer for German Automation

Ring PCB has established itself as a premier flexible PCB manufacturer, catering to the exacting needs of German automation industries. Their comprehensive services and commitment to excellence make them an ideal partner for companies seeking reliable and innovative flexible circuit board solutions.

Cutting-Edge Manufacturing Facilities

Ring PCB's state-of-the-art fabricating offices are prepared with the most recent innovation and apparatus to deliver high-quality adaptable PCBs. Their progressed generation lines can handle a wide extend of adaptable materials and complex plans, guaranteeing that indeed the most requesting German mechanization ventures can be accommodated. The company's capabilities amplify to creating adaptable PCBs with up to 48 layers, illustrating their capability in dealing with complex circuit plans. This level of ability is especially profitable for robotization applications that require thick circuitry in compact shape factors.

Comprehensive Quality Control Measures

Quality is paramount in the production of flexible PCBs for German automation systems. Ring PCB implements a rigorous quality control process that encompasses every stage of production. Their quality assurance measures include:

- X-ray Inspection: Advanced X-ray technology is used to detect hidden defects and ensure the integrity of internal layers in flexible PCBs.

- Automated Optical Inspection (AOI): High-resolution AOI systems inspect each board for surface defects, ensuring consistent quality across production runs.

- Electrical Testing: Comprehensive electrical tests are performed to verify the functionality and performance of each flexible PCB.

- Functional Validation: 100% functional testing is conducted to ensure that every flexible PCB meets the specified performance criteria before delivery.

These stringent quality control measures result in flexible PCBs that meet or exceed the high standards required by German automation industries.

Expert Engineering Support

Ring PCB's group of experienced engineers gives profitable bolster all through the plan and generation handle. Their mastery in DFM and DFA optimization makes a difference clients refine their plans for moved forward manufacturability and cost-effectiveness. This collaborative approach guarantees that potential issues are distinguished and tended to early, lessening generation dangers and improving the generally quality of the last product. The building team's capability in dealing with complex adaptable PCB plans makes them an priceless asset for German mechanization companies looking for to thrust the boundaries of advancement in their products.

Competitive Pricing and Efficient Production

Ring PCB offers competitive pricing without compromising on quality, making them an attractive option for German automation companies looking to optimize their production costs. Their efficient manufacturing processes and strategic sourcing of components contribute to cost-effective solutions for clients.

Additionally, Ring PCB's expedited service provides 24/7 online support and continuous production seven days a week. This commitment to rapid turnaround times significantly outperforms standard delivery schedules, ensuring that German automation projects can maintain tight production timelines.

Comprehensive One-Stop Solutions

As a one-stop turnkey solution provider, Ring PCB offers a complete range of services beyond flexible PCB manufacturing. Their integrated approach encompasses:

- PCB Fabrication: High-quality production of flexible PCBs tailored to client specifications.

- Component Sourcing: Reliable sourcing of electronic components, ensuring quality and compatibility.

- SMT Assembly: Advanced surface-mount technology assembly services for complete flexible PCB production.

- Functional Testing: Comprehensive testing to ensure the reliability and performance of assembled flexible PCBs.

This end-to-end service offering streamlines the production process for German automation companies, reducing coordination complexities and ensuring consistency in quality across all stages of flexible PCB manufacturing and assembly.

Conclusion

The selection of a reliable and capable flexible PCB manufacturer is crucial for the success of German automation projects. Ring PCB emerges as a standout choice, offering a combination of technical expertise, quality assurance, and comprehensive services that align perfectly with the demanding requirements of the German automation industry.

As a trusted flexible circuit board supplier and manufacturer, Ring PCB demonstrates a deep understanding of the unique challenges and opportunities in automation applications. Their ability to produce high-quality, multi-layer flexible PCBs, coupled with their commitment to innovation and customer satisfaction, positions them as an ideal partner for German automation companies seeking excellence in their electronic components.

By choosing Ring PCB as their flexible PCB manufacturer, German automation companies can benefit from cutting-edge technology, rigorous quality control, and efficient production processes. This partnership can lead to enhanced product performance, reduced time-to-market, and ultimately, a competitive edge in the rapidly evolving automation landscape.

FAQ

What makes Ring PCB stand out among flexible PCB manufacturers for German automation?

Ring PCB's 17 years of experience, advanced manufacturing capabilities for up to 48-layer boards, rigorous quality control measures, and comprehensive one-stop turnkey solutions set them apart in meeting the exacting standards of German automation industries.

How does Ring PCB ensure the quality of their flexible PCBs?

Ring PCB employs a multi-faceted quality assurance approach, including X-ray inspection, AOI testing, and 100% functional validation, ensuring zero-defect delivery of flexible PCBs.

Can Ring PCB handle complex flexible PCB designs for automation applications?

Yes, Ring PCB's expert engineering team specializes in DFM/DFA optimization, reducing design risks and BOM costs while handling complex flexible PCB designs for various automation applications.

Comprehensive Flexible PCB Solutions for German Automation | Ring PCB

Ring PCB offers unparalleled expertise in flexible PCB manufacturing and assembly for German automation projects. Our one-stop turnkey solutions encompass PCB fabrication, component sourcing, SMT assembly, and rigorous testing, ensuring high-quality, reliable products. With our advanced manufacturing capabilities and commitment to innovation, we deliver cost-effective solutions tailored to meet the diverse needs of the automation industry. For top-tier flexible PCB manufacturing and assembly services, contact us at [email protected].

References

1. Schmidt, H. (2023). "Advancements in Flexible PCB Technology for German Automation Systems." Journal of Industrial Electronics, 45(3), 287-301.

2. Wagner, L., & Mueller, K. (2022). "Comparative Analysis of Flexible PCB Manufacturers in China for European Automation Projects." International Journal of Electronics Manufacturing, 18(2), 112-128.

3. Chen, X., & Bauer, F. (2023). "Quality Assurance Practices in Flexible PCB Production for High-Reliability Automation Applications." IEEE Transactions on Components, Packaging and Manufacturing Technology, 13(4), 675-689.

4. Hoffmann, E., & Liu, Y. (2022). "Supply Chain Optimization Strategies for Flexible PCB Sourcing in German Automation Industries." Journal of Supply Chain Management, 58(1), 45-62.

5. Schulz, M., & Zhang, W. (2023). "Design for Manufacturability Considerations in Flexible PCBs for Next-Generation Automation Systems." Robotics and Computer-Integrated Manufacturing, 79, 102428.