Inside the Industrial PCBA Manufacturing Process

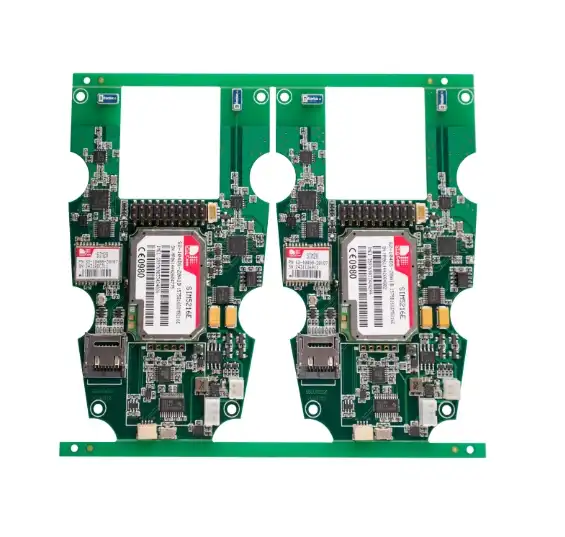

Industrial PCBA (Printed Circuit Board Assembly) manufacturing is a sophisticated process that combines cutting-edge technology with precision engineering. This intricate procedure involves assembling electronic components onto a printed circuit board to create functional electronic devices for industrial applications. The process encompasses several stages, including design, component sourcing, PCB fabrication, assembly, testing, and quality control.

Each step is crucial in ensuring the final product meets the rigorous standards required for industrial use, such as durability, reliability, and performance in harsh environments. The Industrial PCBA manufacturing process is a testament to the advancements in electronics production, enabling the creation of complex systems that power various sectors, from automation and control systems to telecommunications and aerospace.

The Fundamentals of Industrial PCBA Manufacturing

Design and Planning Phase

The journey of an Industrial PCBA begins with meticulous design and planning. Engineers utilize advanced CAD (Computer-Aided Design) software to create schematics and layouts that form the blueprint of the final product. This stage is critical as it determines the functionality, performance, and manufacturability of the PCBA.

Designers must consider factors such as component placement, signal integrity, thermal management, and electromagnetic compatibility. For industrial applications, additional considerations like vibration resistance, temperature tolerance, and protection against environmental factors come into play.

Component Procurement and PCB Fabrication

Once the design is finalized, the next step involves sourcing high-quality components and fabricating the PCB. Industrial PCBAs often require specialized components that can withstand harsh conditions. These may include rugged connectors, high-temperature resistant capacitors, and military-grade ICs.

The PCB fabrication process involves creating the bare board using materials like FR-4, which offers excellent electrical insulation and mechanical strength. For applications requiring higher thermal conductivity or better signal integrity, advanced materials such as polyimide or PTFE may be used.

Surface Finish Selection

The choice of surface finish is crucial in Industrial PCBA manufacturing. Common finishes include ENIG (Electroless Nickel Immersion Gold), HASL (Hot Air Solder Leveling), and OSP (Organic Solderability Preservative). Each finish offers different benefits in terms of solderability, shelf life, and environmental resistance. For instance, ENIG provides excellent corrosion resistance and flat surface, making it ideal for fine-pitch components often used in industrial control systems.

Advanced Assembly Techniques in Industrial PCBA

Surface Mount Technology (SMT) Process

Surface Mount Technology is the cornerstone of modern Industrial PCBA manufacturing. This process begins with applying solder paste to the PCB using a stencil printer. The accuracy of this step is paramount as it directly impacts the quality of component connections. Next, Pick and Place machines precisely position SMD (Surface Mount Device) components onto the board. These machines can place thousands of components per hour with micron-level accuracy, essential for the complex circuits found in industrial equipment.

Reflow Soldering

After component placement, the PCB undergoes reflow soldering. This process involves passing the board through a reflow oven with precisely controlled temperature zones. The solder paste melts and then cools, creating strong, reliable connections between components and the PCB. For Industrial PCBAs, the reflow profile must be carefully optimized to ensure proper soldering without damaging heat-sensitive components. Some industrial applications may require lead-free soldering to comply with environmental regulations, adding another layer of complexity to the process.

Through-Hole Assembly

While SMT dominates modern electronics manufacturing, through-hole assembly still plays a vital role in Industrial PCBA, especially for components that require additional mechanical strength or high power handling capabilities. This process involves inserting component leads through holes in the PCB and soldering them on the opposite side. Wave soldering or selective soldering techniques are commonly used for through-hole assembly in industrial applications, ensuring robust connections that can withstand vibration and thermal stress.

Quality Assurance and Testing in Industrial PCBA Manufacturing

Automated Optical Inspection (AOI)

Quality control is paramount in Industrial PCBA manufacturing, and Automated Optical Inspection (AOI) is a critical tool in this process. AOI systems use high-resolution cameras and sophisticated image processing algorithms to inspect PCBAs for defects such as missing components, incorrect placements, solder bridging, or insufficient solder. These systems can detect issues that might be missed by human inspectors, ensuring a high level of quality and reliability in the final product.

X-ray Inspection

For more complex Industrial PCBAs, especially those with BGAs (Ball Grid Arrays) or dense multi-layer designs, X-ray inspection becomes indispensable. This non-destructive testing method allows inspectors to see through the layers of the PCB, checking for hidden solder joint defects, voids, or misalignments. X-ray inspection is particularly crucial for high-reliability applications in industries like aerospace or medical equipment, where component failure could have severe consequences.

Functional and Environmental Testing

The final stages of Industrial PCBA manufacturing involve rigorous functional and environmental testing. Functional tests verify that the assembled board performs according to its design specifications, checking parameters like voltage levels, signal integrity, and communication interfaces.

Environmental testing subjects the PCBA to conditions it might encounter in its intended application, such as extreme temperatures, humidity, or vibration. These tests ensure that the Industrial PCBA can maintain its performance and reliability in challenging industrial environments, from factory floors to offshore oil rigs.

Conclusion

The Industrial PCBA manufacturing process is a complex symphony of design, technology, and precision engineering. From the initial concept to the final quality checks, each step is crucial in creating reliable, high-performance electronic assemblies that can withstand the demands of industrial applications. As technology continues to evolve, so too does the PCBA manufacturing process, incorporating new materials, techniques, and testing methods to meet the ever-increasing demands of the industrial sector.

Ring PCB: Factory-Direct Industrial PCBA for Automation & IoT

Since 2008, Ring PCB Technology Co., Limited has delivered fast-turn, factory-direct Industrial PCBA solutions for automation and IoT systems. Certified by IPC, RoHS, UL, ISO9001, ISO14001, ISO13485, and IATF16949, we ensure every board meets the highest quality standards. With AOI and X-ray inspection, plus full turnkey services, we provide reliable, cost-effective PCBA solutions tailored to industrial control and smart device applications worldwide.

For those seeking expertise in Industrial PCBA manufacturing, Ring PCB Technology Co., Limited offers comprehensive solutions tailored to meet the diverse needs of industrial applications. With our commitment to quality and innovation, we ensure that your Industrial PCBA projects are in capable hands. To learn more about our services or to discuss your specific requirements, please contact us at [email protected].

References

1. Coombs, C. F. (2018). Printed Circuits Handbook, Seventh Edition. McGraw-Hill Education.

2. Prasad, R. (2019). Surface Mount Technology: Principles and Practice. Springer Nature.

3. Mangin, C. (2020). Industrial PCB Design: Techniques for EMC Compliance. Artech House.

4. Schroeder, S., & Ganesan, S. (2017). Advances in Electronic Assembly: Materials and Processes for Extreme Environments. ASM International.

5. Lee, N. C. (2021). Reflow Soldering Processes and Troubleshooting: SMT, BGA, CSP, and Flip Chip Technologies. Newnes.

Welcome to Ring PCB! Share your inquiry, and receive a tailored quotation!

Ring PCB, your trusted partner for PCB & PCBA Full Turnkey Solutions