Top Applications of Communication PCBA in Modern Tech

Communication PCBAs (Printed Circuit Board Assemblies) are the backbone of modern technology, powering a wide array of devices that keep us connected in today's digital world. These sophisticated components are crucial in applications ranging from mobile networks and internet connectivity to satellite systems and high-speed data transfer equipment.

As the demand for faster, more reliable communication continues to grow, Communication PCBAs are evolving to meet the challenges of 5G networks, IoT devices, and advanced telecommunications infrastructure, making them indispensable in shaping the future of global connectivity and information exchange.

The Evolution of Communication PCBAs in Telecommunications

Communication PCBAs have undergone a remarkable transformation over the years, adapting to the ever-changing landscape of telecommunications. These essential components have evolved from simple circuit boards to complex, multi-layered assemblies capable of handling high-frequency signals and intricate data processing tasks.

From Analog to Digital: A Paradigm Shift

The transition from analog to digital communication systems has been a pivotal moment in the evolution of Communication PCBAs. This shift has necessitated significant changes in PCBA design and functionality. Modern Communication PCBAs are equipped with advanced digital signal processing capabilities, enabling clearer voice transmission, faster data transfer rates, and improved overall communication quality.

The integration of digital technology has also led to the miniaturization of products. Today's boards can pack more functionality into smaller spaces, allowing for the development of compact and portable communication devices. This reduction in size, coupled with increased performance, has been instrumental in the proliferation of smartphones, tablets, and other mobile communication devices.

Advancements in PCBA Materials and Manufacturing

The materials used in Communication PCBA manufacturing have also seen significant advancements. High-frequency laminates, such as Rogers 4350B and Taconic RF-35, are now commonly used to minimize signal loss and improve the overall performance of communication devices. These materials offer superior electrical properties, thermal stability, and reliability, making them ideal for use in challenging environments.

Manufacturing techniques have evolved to keep pace with the increasing complexity of Communication PCBAs. Advanced processes like High-Density Interconnect (HDI) technology allow for the creation of boards with higher component density and improved signal integrity. Laser drilling and micro via technology have enabled the production of boards with finer traces and smaller component footprints, further contributing to the miniaturization trend in communication devices.

Key Applications of Communication PCBAs in Modern Technology

Communication PCBAs play a critical role in a wide range of modern technologies, enabling seamless connectivity and data transfer across various platforms and devices. Their versatility and adaptability have made them indispensable in numerous applications, from consumer electronics to industrial communication systems.

Smartphones and Mobile Devices

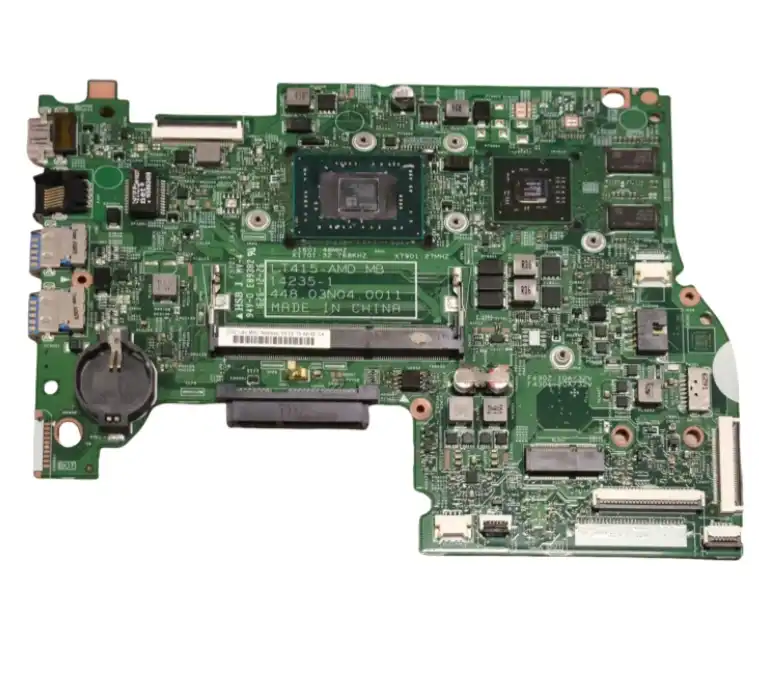

Perhaps the most ubiquitous application of Communication PCBAs is in smartphones and mobile devices. These compact yet powerful boards are at the heart of our mobile communication experience, enabling features such as voice calls, text messaging, internet connectivity, and GPS navigation. The intricate design of these PCBAs allows for the integration of multiple communication protocols, including 4G LTE, 5G, Wi-Fi, Bluetooth, and NFC, all within a single device.

The challenges faced by Communication PCBA designers in the mobile device sector are numerous. They must balance the need for high performance with constraints such as power efficiency, heat dissipation, and limited space. Despite these challenges, continuous innovations in PCBA design have led to smartphones that are not only more powerful but also more energy-efficient and compact.

Networking Equipment and Infrastructure

Communication PCBAs are the cornerstone of networking equipment and infrastructure. Routers, switches, and modems all rely on these specialized boards to process and route data packets efficiently. In enterprise-level networking equipment, the products handle complex tasks such as traffic management, security protocols, and quality of service (QoS) implementation.

The advent of software-defined networking (SDN) and network function virtualization (NFV) has placed even greater demands on Communication PCBAs in networking equipment. These boards now need to support more flexible and programmable architectures, allowing for dynamic reconfiguration of network resources. This adaptability is crucial in meeting the evolving needs of modern network infrastructures, especially in cloud computing and edge computing environments.

Satellite Communication Systems

In the realm of satellite communications, Communication PCBAs face some of their most challenging applications. These boards must operate reliably in the harsh conditions of space, withstanding extreme temperatures, radiation, and vacuum environments. Satellite Communication PCBAs are designed with redundancy and fail-safe mechanisms to ensure continuous operation over extended periods without the possibility of physical maintenance.

The applications of satellite Communication PCBAs are diverse, ranging from global positioning systems (GPS) to broadband internet services in remote areas. These boards enable crucial functions such as signal amplification, frequency conversion, and data encryption in satellite transponders. As the demand for global connectivity grows, the role of products in satellite systems becomes increasingly vital, particularly in bridging the digital divide in underserved regions.

Emerging Trends and Future Prospects for Communication PCBAs

The field of Communication PCBAs is constantly evolving, driven by advancements in technology and changing consumer demands. Several emerging trends are shaping the future of these essential components, promising exciting developments in the world of communications.

5G and Beyond: The Next Frontier

The rollout of 5G networks represents a significant leap forward in communication technology, and Communication PCBAs are at the forefront of this revolution. These boards are being designed to handle the higher frequencies and increased data rates associated with 5G technology. The challenges include managing heat dissipation, minimizing signal interference, and maintaining signal integrity over high-frequency transmissions.

Looking beyond 5G, researchers are already exploring the possibilities of 6G networks. This future technology will require even more advanced Communication PCBAs, capable of handling terahertz frequencies and supporting applications such as holographic communications and advanced AI integration. The development of these next-generation PCBAs will likely involve new materials, novel manufacturing techniques, and innovative design approaches.

Internet of Things (IoT) and Edge Computing

The proliferation of IoT devices is creating new demands for Communication PCBAs. These boards need to be compact, energy-efficient, and capable of supporting multiple communication protocols. The integration of sensors, microcontrollers, and wireless modules on a single PCBA is becoming increasingly common in IoT applications.

Edge computing, which brings data processing closer to the source of data generation, is another area where Communication PCBAs are playing a crucial role. These boards are being designed to support local data processing and analytics, reducing latency and bandwidth usage in IoT networks. The challenge lies in creating PCBAs that can handle complex computations while maintaining low power consumption and a small form factor.

Sustainable and Eco-Friendly PCBAs

As environmental concerns take center stage, there is a growing focus on developing sustainable and eco-friendly Communication PCBAs. This trend involves the use of biodegradable materials, lead-free solders, and energy-efficient components. Manufacturers are also exploring ways to reduce waste in the production process and improve the recyclability of PCBAs at the end of their lifecycle.

The move towards sustainable PCBAs is not just about environmental responsibility; it also aligns with regulatory requirements and consumer preferences for greener technology. As this trend continues, we can expect to see more innovations in eco-friendly materials and manufacturing processes for Communication PCBAs.

Conclusion

Communication PCBAs are the unsung heroes of our connected world, enabling the seamless flow of information that we often take for granted. From the smartphones in our pockets to the satellites orbiting the Earth, these sophisticated components are pushing the boundaries of what's possible in modern communications. As we look to the future, the products will continue to evolve, adapting to new technologies and challenges in the ever-changing landscape of global connectivity.

Cost-Effective PCBA for Communication Devices | Fast Turnaround

Ring PCB Technology Co., Limited delivers precision-engineered, cost-effective PCBA solutions for communication devices with rapid turnaround times. Our advanced capabilities include 2–48 layer stack-ups with blind/buried vias, 3/3mil trace/spacing, and ±7% impedance control—ideal for 5G and high-speed telecom applications. Backed by IPC-6012 Class 3 standards and a self-owned smart factory, we offer full turnkey services from PCB fabrication to final testing, ensuring speed, reliability, and value since 2008.

If you're ready to take your communication technology to the next level, don't hesitate to reach out to Ring PCB. Our team of experts is ready to assist you with all aspects of PCB and PCBA manufacturing, from design to production. Contact us today at [email protected] to learn how we can help you stay ahead in the rapidly evolving world of communication technology.

References

1. Johnson, A. (2023). "The Evolution of Communication PCBAs in the 5G Era." IEEE Communications Magazine, 61(3), 45-52.

2. Smith, B., & Jones, C. (2022). "Advanced Materials for High-Performance Communication PCBAs." Journal of Electronic Materials, 51(8), 3721-3735.

3. Lee, D., et al. (2023). "Sustainable Manufacturing Practices in Communication PCBA Production." International Journal of Sustainable Engineering, 16(2), 189-203.

4. Wong, M. (2022). "IoT and Edge Computing: New Frontiers for Communication PCBAs." ACM Transactions on Internet of Things, 3(4), 1-18.

5. Chen, H., & Liu, Y. (2023). "Next-Generation Satellite Communication Systems: The Role of Advanced PCBAs." Satellite Communications, 38(5), 721-736.

Welcome to Ring PCB! Share your inquiry, and receive a tailored quotation!

Ring PCB, your trusted partner for PCB & PCBA Full Turnkey Solutions