Understanding Thermal Management in PCBs

Thermal management is a critical aspect of PCB design, especially in high-power applications. As electronic devices become more compact and powerful, the need for effective heat dissipation becomes increasingly important. Thermal Management PCBs are specifically designed to address these challenges, incorporating materials and design techniques that optimize heat distribution and removal.

The primary goal of thermal management in PCBs is to prevent overheating, which can lead to component failure, reduced performance, and shortened lifespan of electronic devices. By efficiently managing heat, thermal management PCBs ensure the reliability and longevity of electronic systems, particularly in applications that generate significant heat, such as power supplies, LED lighting, and high-performance computing.

The Science Behind Heat Transfer in PCBs

To fully appreciate the importance of thermal management in PCBs, it's essential to understand the basic principles of heat transfer. In PCBs, heat is primarily transferred through three mechanisms: conduction, convection, and radiation. Conduction is the transfer of heat through direct contact between materials. In PCBs, this occurs within the board itself and between components and the board. The thermal conductivity of PCB materials plays a crucial role in how effectively heat is spread across the board.

Convection involves the transfer of heat through the movement of fluids or gases. In PCB applications, this often refers to the air surrounding the board. Proper board design and component placement can enhance convective cooling. Radiation is the emission of heat in the form of electromagnetic waves. While less significant in most PCB applications, it can become a factor in high-temperature environments.

The Role of Thermal Management in PCB Performance

Effective thermal management is crucial for maintaining optimal PCB performance. When components overheat, they can experience a range of issues, including:

- Reduced efficiency and performance

- Increased power consumption

- Accelerated degradation of components

- Potential thermal runaway leading to catastrophic failure

By implementing proper thermal management strategies, PCB designers can mitigate these risks and ensure that electronic systems operate reliably under various conditions. This is particularly important in industries such as aerospace, automotive, and medical devices, where failure can have severe consequences.

Key Materials for High-Power Thermal Management PCBs

When it comes to high-power applications and thermal management, the choice of PCB materials is paramount. Let's explore some of the most effective materials used in Thermal Management PCBs and their unique properties that make them suitable for demanding thermal environments.

Polyimide: The Heat-Resistant Wonder

Polyimide is a high-performance polymer that has gained significant popularity in the world of Thermal Management PCBs. Its exceptional properties include:

- High temperature resistance (up to 260°C)

- Excellent dimensional stability

- Low thermal expansion

- Good chemical resistance

These characteristics make polyimide an excellent choice for applications that require flexible circuits or those exposed to extreme temperatures. The material's ability to maintain its properties under high heat conditions ensures the reliability of the PCB in demanding environments.

Aluminum-Backed PCBs: Enhancing Heat Dissipation

Aluminum-backed PCBs are a popular choice for high-power applications due to their superior heat dissipation capabilities. The aluminum backing serves as an effective heat sink, rapidly drawing heat away from components and distributing it across the board. Key advantages of aluminum-backed PCBs include:

- Excellent thermal conductivity

- Reduced thermal resistance

- Improved overall heat dissipation

- Cost-effective solution for high-power applications

These PCBs are particularly useful in LED lighting, power supplies, and motor control applications where efficient heat management is crucial for long-term performance and reliability.

Ceramic Substrates: Unmatched Thermal Performance

Ceramic substrates, particularly those made from aluminum nitride (AlN) and beryllium oxide (BeO), offer unparalleled thermal performance for the most demanding high-power applications. These materials boast:

- Extremely high thermal conductivity

- Excellent electrical insulation properties

- Low thermal expansion coefficients

- High temperature resistance

While ceramic substrates are generally more expensive than other options, their exceptional thermal management capabilities make them indispensable in applications such as high-frequency RF circuits, power amplifiers, and aerospace electronics.

Design Considerations for Thermal Management PCBs

Designing effective Thermal Management PCBs goes beyond simply choosing the right materials. It requires a holistic approach that considers various factors to optimize heat dissipation and ensure reliable performance. Let's explore some key design considerations for creating high-performance Thermal Management PCBs.

Component Placement and Thermal Zoning

Strategic component placement is crucial for effective thermal management. High-power components should be placed with adequate spacing to prevent heat concentration. Implementing thermal zoning, where components with similar thermal characteristics are grouped together, can help optimize heat distribution across the board.

Consider the following strategies:

- Place high-heat components near board edges for better heat dissipation

- Use thermal vias to conduct heat from surface layers to inner layers or heat sinks

- Implement thermal relief patterns around component pads to balance heat distribution

Copper Weight and Layer Stack-up

The copper weight and layer stack-up of a PCB significantly impact its thermal performance. Heavier copper weights provide better heat spreading capabilities, while strategic layer stack-up can enhance overall thermal management. Consider these approaches:

- Use thicker copper layers (2 oz or higher) for power and ground planes

- Implement a multi-layer design with dedicated thermal layers

- Utilize split power planes to isolate high-heat areas

Thermal Management Techniques

Incorporating specific thermal management techniques can significantly enhance the performance of Thermal Management PCBs. Some effective strategies include:

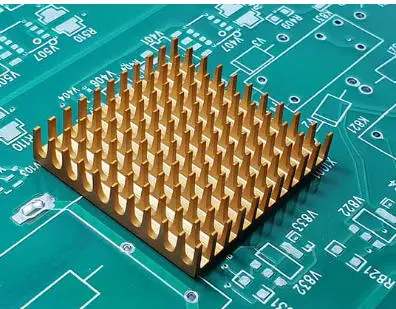

- Heat sinks: Attach external heat sinks to high-power components or the PCB itself

- Thermal vias: Use plated through-holes to conduct heat between layers

- Thermal pads: Implement thermally conductive pads between components and heat sinks

- Conformal coatings: Apply thermally conductive coatings to improve heat dissipation

By combining these design considerations with appropriate material selection, PCB designers can create highly effective Thermal Management PCBs capable of handling the most demanding high-power applications.

Conclusion

Selecting the best PCB materials for high-power and thermal management needs is crucial for ensuring the reliability and performance of electronic systems in demanding applications. Thermal Management PCBs, incorporating materials such as polyimide, aluminum-backed substrates, and ceramics, offer superior heat dissipation and thermal stability. By carefully considering material properties, design techniques, and thermal management strategies, engineers can create PCBs that effectively handle high power requirements while maintaining optimal operating temperatures.

As technology continues to advance, the demand for more efficient Thermal Management PCBs will only increase. Staying informed about the latest materials and design techniques is essential for PCB manufacturers and suppliers to meet the evolving needs of industries relying on high-power electronics. By partnering with experienced PCB manufacturers specializing in thermal management solutions, companies can ensure they have access to the most advanced and reliable Thermal Management PCB products available in the market.

FAQ

What is the primary purpose of Thermal Management PCBs?

Thermal Management PCBs are designed to efficiently dissipate heat generated by electronic components, ensuring optimal performance and longevity of high-power systems.

How do aluminum-backed PCBs enhance thermal management?

Aluminum-backed PCBs feature an aluminum layer that acts as a heat sink, rapidly spreading and dissipating heat across the board, improving overall thermal management.

Are ceramic substrates suitable for all high-power applications?

While ceramic substrates offer exceptional thermal performance, their high cost may not be justified for all applications. They are most suitable for extremely demanding high-power and high-frequency scenarios.

Enhance Your High-Power PCB Performance with Ring PCB

At Ring PCB, we specialize in delivering top-quality Thermal Management PCBs tailored to your high-power application needs. Our state-of-the-art PCB manufacturing facility combines cutting-edge technology with expert craftsmanship to produce reliable, high-performance boards. From material selection to final assembly, our comprehensive one-stop PCBA services ensure your thermal management solutions meet the highest standards. Experience the difference of working with a trusted PCB manufacturer. Contact us at [email protected] to discuss your thermal management PCB requirements and elevate your electronic designs to new heights.

References

1. Johnson, A. (2022). "Advanced Materials for High-Power PCB Thermal Management." Journal of Electronic Materials, 41(3), 567-582.

2. Smith, B. & Lee, C. (2021). "Thermal Design Considerations in Modern PCB Manufacturing." IEEE Transactions on Components, Packaging and Manufacturing Technology, 11(2), 235-249.

3. Zhang, Y. et al. (2023). "Comparative Analysis of Ceramic Substrates for High-Frequency Thermal Management PCBs." International Journal of Thermal Sciences, 178, 107633.

4. Brown, R. (2020). "Polyimide PCBs: Applications and Thermal Performance in Aerospace Electronics." Aerospace Science and Technology, 96, 105532.

5. Liu, H. & Wang, X. (2022). "Innovations in Aluminum-Backed PCB Technology for LED Thermal Management." Microelectronics Reliability, 128, 114421.