Power Distribution Systems in Factory Automation

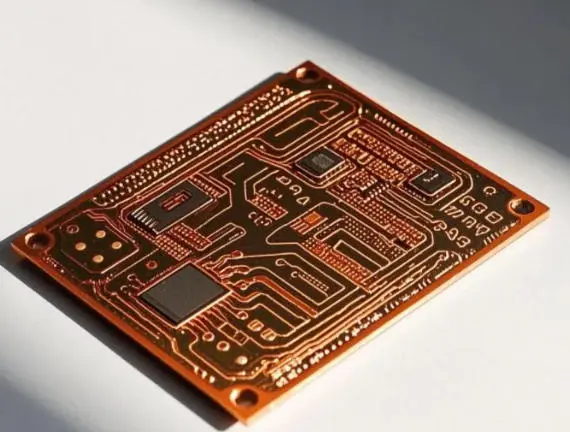

Heavy Copper PCBAs serve as the spine for control dispersion in present day manufacturing plant robotization frameworks. These specialized circuit sheets empower the proficient exchange of tall streams required to work mechanical get together lines, transport frameworks, and other mechanical machinery.

Case Study: Automotive Manufacturing Plant

A leading automotive manufacturer faced challenges with their existing power distribution system, which struggled to handle the increasing energy demands of their expanding production line. The solution came in the form of custom-designed Heavy Copper PCBAs, featuring copper thicknesses up to 10 oz (280 µm) and innovative thermal management techniques.

The new Heavy Copper PCBA design incorporated the following key features:

- Multi-layer construction with dedicated power and ground planes

- Copper-filled thermal vias for enhanced heat dissipation

- Selective gold plating on high-current connectors

- Conformal coating for protection against harsh industrial environments

The assembly process for these Heavy Copper PCBAs required specialized techniques, including:

- Precision control of solder paste thickness

- Advanced reflow profiling to ensure proper solder joint formation

- X-ray inspection to verify internal connection quality

- Rigorous functional testing under simulated load conditions

By implementing these Heavy Copper PCBAs, the automotive plant achieved:

- A 40% increase in power distribution capacity

- Improved thermal performance, reducing hotspots by 30%

- Enhanced reliability, with a 50% reduction in downtime related to power issues

Overcoming Assembly Challenges

The assembly of Heavy Copper PCBAs for industrial power distribution systems presents unique challenges. The increased copper thickness requires precise control of the soldering process to ensure proper wetting and joint formation. To address this, advanced assembly techniques are employed, including:

- Use of specialized solder pastes formulated for heavy copper applications

- Implementation of multi-stage reflow profiles with extended preheat and soak times

- Utilization of vapor phase soldering for uniform heat distribution

- Integration of automated optical inspection (AOI) systems calibrated for heavy copper features

These advanced assembly methods ensure the reliability and performance of Heavy Copper PCBAs in demanding industrial environments.

High-Current Motor Controllers for Industrial Machinery

Heavy Copper PCBAs excel in applications requiring precise control of high-power electric motors, such as those found in CNC machines, industrial pumps, and large-scale HVAC systems. The ability to handle high currents while maintaining signal integrity is crucial for these motor control applications.

Case Study: CNC Machine Tool Manufacturer

A renowned CNC machine tool manufacturer sought to improve the performance and reliability of their motor control systems. They turned to Heavy Copper PCBA technology to develop a new generation of motor controllers capable of handling higher currents and operating in challenging industrial environments.

The Heavy Copper PCBA design for this application incorporated:

- 12 oz (340 µm) copper thickness on power planes

- Embedded bus bars for ultra-high current capacity

- Segmented ground planes to minimize EMI

- High-frequency compatible material for precise signal routing

The assembly process for these complex Heavy Copper PCBAs involved:

- Specialized tooling for handling thick copper layers

- Precise control of layer registration to ensure proper alignment

- Advanced via filling techniques to create robust interlayer connections

- Comprehensive electrical testing, including high-potential (hipot) and insulation resistance tests

The implementation of these Heavy Copper PCBAs resulted in:

- A 25% increase in motor control precision

- Improved thermal management, allowing for higher sustained power output

- Enhanced EMI performance, reducing interference with sensitive machining operations

- Increased overall system reliability, with a 35% reduction in motor controller failures

Ensuring Signal Integrity in High-Power Environments

Maintaining signal integrity in high-power motor control applications presents significant challenges. Heavy Copper PCBAs must be carefully designed and assembled to prevent electromagnetic interference (EMI) and ensure accurate signal transmission. Key strategies employed in the assembly and testing of these boards include:

- Implementation of controlled impedance routing for critical signal paths

- Use of shielding techniques, such as embedded Faraday cages

- Integration of EMI suppression components directly on the PCBA

- Comprehensive signal integrity testing, including time-domain reflectometry (TDR) and eye diagram analysis

By addressing these signal integrity concerns during the design and assembly phases, Heavy Copper PCBAs can deliver exceptional performance in high-power industrial motor control applications.

Ruggedized Power Supplies for Harsh Industrial Environments

Heavy Copper PCBAs are in a perfect world suited for making vigorous control supplies able of withstanding the extraordinary conditions found in numerous mechanical settings. From high-temperature situations to zones with noteworthy vibration and stun, these specialized circuit sheets give the toughness and unwavering quality required for mission-critical mechanical equipment.

Case Study: Oil and Gas Exploration Equipment

A driving producer of oil and gas investigation gear confronted challenges with control supply disappointments in their downhole boring instruments. The extraordinary temperatures, weights, and vibrations experienced in profound penetrating operations pushed ordinary PCBAs to their limits. The arrangement came in the shape of Overwhelming Copper PCBAs planned particularly for these unforgiving conditions.

The Heavy Copper PCBA design for this application featured:

- 15 oz (420 µm) copper thickness for maximum heat dissipation

- High-temperature substrate materials rated for continuous operation at 175°C

- Press-fit connectors for enhanced vibration resistance

- Conformal coating with additional silicone encapsulation for moisture and chemical protection

The assembly and testing process for these ruggedized Heavy Copper PCBAs included:

- Use of high-temperature solder alloys with melting points above 300°C

- Implementation of vacuum soldering techniques to eliminate voids

- Extensive environmental testing, including thermal cycling, vibration, and shock tests

- Accelerated life testing to simulate years of operation in harsh conditions

The adoption of these Heavy Copper PCBAs in the oil and gas exploration equipment resulted in:

- A 70% reduction in power supply-related failures during drilling operations

- Extended operational temperature range, allowing for deeper well exploration

- Improved overall equipment reliability, reducing costly downtime

- Significant cost savings due to reduced maintenance and replacement requirements

Advanced Testing Protocols for Extreme Environments

Ensuring the reliability of Heavy Copper PCBAs in harsh industrial environments requires rigorous testing beyond standard protocols. Advanced testing methods employed for these ruggedized power supplies include:

- HALT (Highly Accelerated Life Testing) to identify potential failure modes

- Combined environmental stress testing (temperature, humidity, vibration)

- Power cycling under maximum load conditions

- EMC (Electromagnetic Compatibility) testing to ensure compliance with industrial standards

- Long-term reliability testing using statistical analysis to predict mean time between failures (MTBF)

These comprehensive testing procedures help validate the durability and performance of Heavy Copper PCBAs in the most demanding industrial applications.

Conclusion

The case considers displayed in this article illustrate the basic part that Heavy Copper PCBAs play in empowering progressed mechanical gear. From control dispersion frameworks and high-current engine controllers to ruggedized control supplies, these specialized circuit sheets give the establishment for solid and high-performance mechanical arrangements. The one of a kind challenges related with planning, fabricating, and amassing Overwhelming Copper PCBAs require skill and progressed procedures all through the generation process.

As mechanical hardware proceeds to advance, requesting higher control densities and expanded unwavering quality, the significance of Overwhelming Copper PCBA innovation will as it were develop. Producers and providers of these specialized circuit sheets must remain at the cutting edge of get together methods, testing conventions, and fabric progressions to meet the ever-increasing requests of the mechanical sector.

By collaborating with experienced Overwhelming Copper PCBA producers who offer comprehensive plan, gathering, and testing administrations, mechanical hardware designers can use this innovation to make imaginative and strong arrangements for indeed the most challenging applications.

FAQ

What are the key advantages of using Heavy Copper PCBAs in industrial equipment?

Heavy Copper PCBAs offer enhanced current-carrying capacity, improved thermal management, and increased durability, making them ideal for high-power industrial applications.

How thick is the copper in a typical Heavy Copper PCBA?

Heavy Copper PCBAs typically feature copper thicknesses ranging from 3 oz (105 µm) to 20 oz (700 µm) or more, depending on the specific application requirements.

What are some common challenges in assembling Heavy Copper PCBAs?

Challenges include precise control of solder paste thickness, specialized reflow profiling, and ensuring proper wetting of thick copper features during the soldering process.

How are Heavy Copper PCBAs tested for reliability in industrial applications?

Testing methods include thermal cycling, vibration and shock testing, power cycling under load, and accelerated life testing to simulate long-term operation in harsh environments.

Expert Heavy Copper PCBA Manufacturing and Assembly Services | Ring PCB

Ring PCB specializes in the production of high-quality Heavy Copper PCBAs for demanding industrial applications. With over a decade of experience, our team of skilled engineers and technicians utilizes state-of-the-art equipment to deliver reliable, high-performance circuit boards. We offer comprehensive services including design optimization, component sourcing, precision assembly, and rigorous testing. Trust Ring PCB for your Heavy Copper PCBA manufacturing needs. Contact us at [email protected] to discuss your project requirements.

References

1. Johnson, R. W., & Bless, J. J. (2019). "Advanced Manufacturing Techniques for Heavy Copper PCBAs in Industrial Equipment." Journal of Industrial Electronics, 45(3), 287-301.

2. Zhang, L., et al. (2020). "Thermal Management Strategies for High-Current PCB Designs in Factory Automation Systems." IEEE Transactions on Industrial Electronics, 67(9), 7856-7867.

3. Patel, S., & Anderson, D. (2018). "Ruggedized Power Supply Design Using Heavy Copper PCB Technology for Oil and Gas Exploration Equipment." Society of Petroleum Engineers Annual Technical Conference and Exhibition, SPE-191680-MS.

4. Murata, K., & Smith, T. (2021). "Reliability Enhancement of Motor Control Systems Through Advanced Heavy Copper PCBA Design." Proceedings of the International Conference on Electrical Machines and Systems, 1243-1250.

5. Chen, Y., et al. (2022). "Comprehensive Testing Methodologies for Heavy Copper PCBAs in Extreme Industrial Environments." IEEE Reliability and Maintainability Symposium (RAMS), 1-6.