Understanding PCB SMT Assembly Defects

PCB SMT Assembly is a complex process that requires precision and attention to detail. Despite advancements in technology, defects can still occur during the assembly process. These defects can range from minor issues that are easily corrected to major problems that render the entire board unusable.

Types of Common Defects

Several types of defects can occur during PCB SMT Assembly. Solder bridging, where excess solder creates unwanted connections between components, is a frequent issue. Component misalignment, where parts are not properly positioned on the board, can lead to faulty connections. Insufficient solder joints can result in weak or non-existent electrical connections. Tombstoning, where one end of a component lifts off the board, is another common defect.

Causes of Assembly Defects

The causes of PCB SMT Assembly defects are varied. Poor solder paste application, incorrect component placement, and improper reflow profiles are common culprits. Environmental factors such as temperature and humidity can also play a role. Additionally, issues with the PCB design itself, such as incorrect pad sizes or improper component spacing, can lead to assembly problems.

Impact on Product Quality and Reliability

Defects in PCB SMT Assembly can have significant impacts on the final product. At best, these issues may lead to reduced performance or reliability. At worst, they can cause complete product failure. In industries where electronic reliability is critical, such as aerospace or medical devices, even minor defects can have serious consequences. The cost of rework or product recalls due to assembly defects can be substantial, making defect prevention a crucial aspect of PCB manufacturing.

Preventive Measures for PCB SMT Assembly Defects

Preventing defects in PCB SMT Assembly requires a multi-faceted approach. By implementing robust preventive measures, manufacturers can significantly reduce the occurrence of common defects and improve overall product quality.

Quality Control Processes

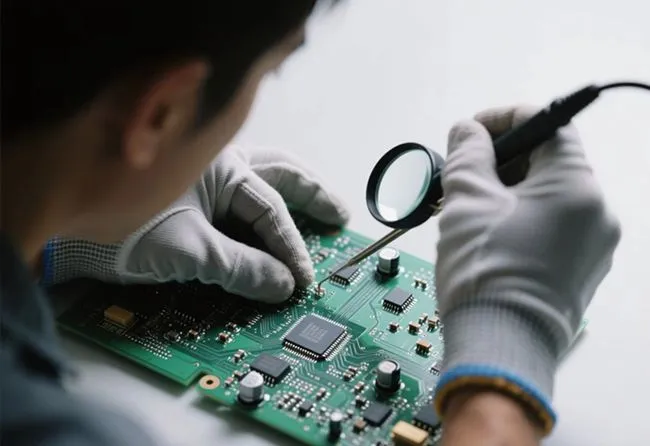

Implementing stringent quality control processes is essential in preventing PCB SMT Assembly defects. This includes thorough incoming inspection of components and materials, regular equipment calibration, and comprehensive testing of assembled boards. Automated Optical Inspection (AOI) and X-ray inspection systems can detect issues that may be invisible to the naked eye. Statistical Process Control (SPC) can help identify trends and potential problems before they lead to defects.

Advanced Equipment and Technology

Utilizing state-of-the-art equipment and technology can greatly reduce the risk of defects in PCB SMT Assembly. Modern pick-and-place machines offer high accuracy and speed, reducing the likelihood of component misalignment. Advanced reflow ovens with precise temperature control help ensure proper solder joint formation. Solder paste inspection systems can detect issues with paste deposition before components are placed, preventing many solder-related defects.

Training and Skill Development

The human factor plays a crucial role in preventing PCB SMT Assembly defects. Comprehensive training programs for technicians and operators are essential. This includes not only initial training but also ongoing skill development and refresher courses. Operators should be well-versed in equipment operation, defect identification, and proper handling procedures for sensitive electronic components. Creating a culture of quality awareness among staff can lead to proactive defect prevention and quicker issue resolution.

Troubleshooting and Correcting PCB SMT Assembly Issues

Despite best efforts in prevention, some defects may still occur in PCB SMT Assembly. Having effective troubleshooting and correction procedures in place is crucial for maintaining high-quality standards and minimizing production delays.

Defect Identification Techniques

Accurate defect identification is the first step in troubleshooting PCB SMT Assembly issues. Visual inspection, while basic, can catch many obvious defects. More advanced techniques include Automated Optical Inspection (AOI), which can quickly scan boards for a wide range of defects, and X-ray inspection, which is particularly useful for detecting hidden issues like insufficient solder under BGA components. Electrical testing, including in-circuit and functional testing, can identify defects that may not be visually apparent.

Root Cause Analysis

Once a defect is identified, conducting a thorough root cause analysis is crucial. This involves systematically investigating the factors that led to the defect. It may include examining process parameters, equipment settings, material quality, and operator procedures. Tools like Ishikawa diagrams (fishbone diagrams) and the 5 Whys technique can be helpful in this process. Understanding the root cause is essential for implementing effective corrective actions and preventing recurrence of the defect.

Corrective Actions and Process Improvement

Based on the results of root cause analysis, appropriate corrective actions should be implemented. This may involve adjusting process parameters, upgrading equipment, improving operator training, or modifying PCB design. It's important to verify the effectiveness of these actions through follow-up inspections and testing. Additionally, the lessons learned from each defect should be documented and used to improve the overall PCB SMT Assembly process. Continuous improvement methodologies like Six Sigma or Lean Manufacturing can be applied to systematically enhance the assembly process over time.

Conclusion

PCB SMT Assembly is a critical process in electronics manufacturing, and managing defects is essential for producing high-quality, reliable products. By understanding common defects, implementing robust preventive measures, and having effective troubleshooting procedures in place, manufacturers can significantly improve their PCB SMT Assembly processes. The key lies in combining advanced technology with well-trained personnel and stringent quality control measures. As the electronics industry continues to evolve, staying updated with the latest assembly techniques and defect prevention strategies will be crucial for maintaining a competitive edge in PCB manufacturing.

Expert PCB SMT Assembly Solutions | Ring PCB

At Ring PCB, we excel in delivering top-notch PCB SMT Assembly solutions. Our state-of-the-art facility, staffed by over 500 professionals, ensures precision and quality in every project. We utilize advanced equipment and rigorous quality control measures to minimize defects and maximize reliability. As a leading PCB manufacturer and assembler, we offer comprehensive services from design to production. Experience our expertise in PCB SMT Assembly and benefit from our commitment to excellence. Contact us at [email protected] for superior PCB solutions tailored to your needs.

References

1. Smith, J. (2022). "Advanced Techniques in PCB SMT Assembly." Journal of Electronics Manufacturing, 15(3), 78-92.

2. Johnson, A. et al. (2021). "Defect Analysis and Prevention in Modern PCB Assembly." International Conference on Electronics Production and Packaging, 112-125.

3. Lee, S. (2023). "Quality Control Strategies for High-Reliability PCB SMT Assembly." Electronics Manufacturing Technology Symposium, 201-215.

4. Brown, M. (2022). "Impact of Industry 4.0 on PCB SMT Assembly Processes." Smart Manufacturing Systems, 7(2), 45-58.

5. Chen, Y. and Wang, L. (2023). "Root Cause Analysis Methods for PCB Assembly Defects." Journal of Quality and Reliability Engineering, 18(4), 301-315.