Exploring The Importance Of PCBs in Efficient LED Lighting Design

Printed Circuit Boards (PCBs) play a crucial role in the design and performance of efficient LED lighting systems. As the backbone of modern electronics, PCBs provide the necessary foundation for mounting, connecting, and powering LED components. In LED lighting applications, PCBs not only serve as a structural support but also contribute significantly to heat management, current distribution, and overall system reliability. The integration of PCB and PCBA manufacturing techniques has revolutionized LED lighting design, enabling compact, energy-efficient, and long-lasting illumination solutions across various industries and applications.

The Role of PCBs in LED Lighting Systems

Thermal Management and Heat Dissipation

One of the primary challenges in LED lighting design is effective heat management. LEDs generate significant heat during operation, which can negatively impact their performance and lifespan if not properly addressed. PCBs, especially those designed for LED applications, play a vital role in heat dissipation.

Metal-core PCBs (MCPCBs) are particularly popular in LED lighting due to their superior thermal conductivity. These boards typically feature an aluminum base layer that efficiently transfers heat away from the LED components. The thermal management capabilities of MCPCBs help maintain optimal operating temperatures, ensuring consistent light output and extending the lifespan of LED fixtures.

Current Distribution and Power Efficiency

Efficient current distribution is essential for uniform illumination and optimal LED performance. PCBs designed for LED lighting applications often incorporate thick copper layers and specialized trace layouts to minimize voltage drops and ensure even current distribution across multiple LEDs.

The PCBA manufacturing process allows for precise control over trace widths and copper thickness, enabling designers to create PCBs that can handle high current loads while maintaining efficiency. This level of control is crucial for achieving the desired light output and color consistency in LED lighting systems.

Compact and Flexible Design Options

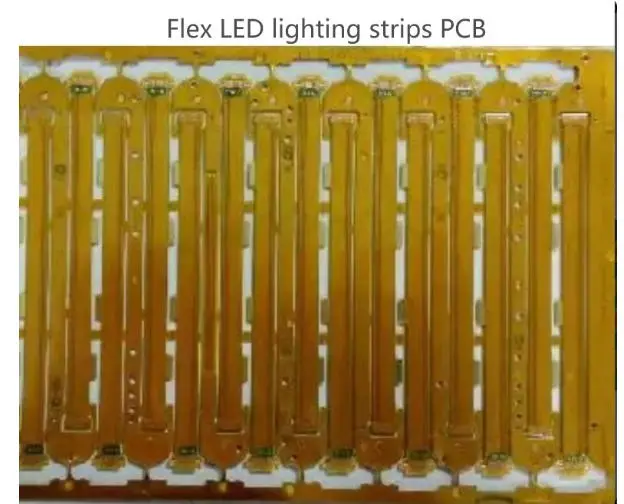

The versatility of PCB design and PCBA manufacturing techniques allows for the creation of compact and flexible LED lighting solutions. Rigid-flex PCBs, for instance, combine the benefits of rigid boards with the flexibility of flexible circuits, enabling innovative form factors and space-saving designs.

These advanced PCB technologies support the development of slim, lightweight LED fixtures that can be easily integrated into various applications, from automotive lighting to architectural illumination. The ability to create custom-shaped PCBs also allows designers to optimize space utilization and achieve unique lighting configurations.

Advancements in PCB Technology for LED Lighting

High-Frequency PCB Materials

As LED lighting systems become more sophisticated, incorporating features like dimming, color control, and wireless connectivity, the need for high-frequency PCB materials has increased. Materials such as Rogers and Taconic offer improved signal integrity and reduced signal loss, which is crucial for maintaining the performance of advanced LED control circuits.

The integration of these high-performance materials in PCBA manufacturing processes has enabled the development of smart lighting systems with enhanced functionality and reliability. These advancements contribute to more efficient and responsive LED lighting solutions across various applications.

Embedded Components and HDI Technology

The drive towards miniaturization and increased functionality in LED lighting has led to the adoption of embedded component technology and High-Density Interconnect (HDI) PCBs. Embedded components allow for the integration of passive elements directly within the PCB layers, reducing the overall footprint of the lighting module.

HDI technology, with its fine line widths and small via sizes, enables the creation of compact, multi-layer PCBs that can accommodate complex circuitry in a limited space. These advancements in PCB and PCBA manufacturing techniques have paved the way for highly integrated LED lighting solutions with advanced features and improved performance.

Enhanced Surface Finishes for Improved Reliability

The reliability and longevity of LED lighting systems are heavily influenced by the quality of electrical connections between components and the PCB. Advanced surface finishes, such as Electroless Nickel Immersion Gold (ENIG) and Immersion Silver, offer improved solderability and protection against oxidation and corrosion.

These surface finishes, applied during the PCBA manufacturing process, ensure robust and reliable connections between LED components and the PCB. The enhanced durability of these finishes contributes to the overall reliability and lifespan of LED lighting products, particularly in harsh environmental conditions.

Future Trends in PCB Design for LED Lighting

Integration of IoT and Smart Lighting Capabilities

The future of LED lighting is closely tied to the Internet of Things (IoT) and smart home technologies. PCB designs for LED lighting are increasingly incorporating wireless communication modules, sensors, and microcontrollers to enable smart lighting features.

These advanced PCBs support functionalities such as remote control, automated brightness adjustment, and integration with smart home ecosystems. The PCBA manufacturing process for these smart LED lighting systems requires careful consideration of signal integrity, EMI shielding, and component placement to ensure optimal performance of both the lighting and smart features.

Sustainable and Eco-Friendly PCB Materials

As environmental concerns continue to grow, the LED lighting industry is exploring more sustainable PCB materials and manufacturing processes. Halogen-free and lead-free PCB materials are becoming increasingly popular, aligning with global initiatives for reducing environmental impact.

Advancements in PCBA manufacturing techniques are also focusing on reducing waste and energy consumption during production. These eco-friendly approaches not only contribute to a more sustainable industry but also align with the energy-efficient nature of LED lighting technology.

3D Printed Electronics for Custom Lighting Solutions

The emergence of 3D printed electronics presents exciting possibilities for LED lighting design. This technology allows for the creation of three-dimensional circuit structures, enabling unique form factors and highly customized lighting solutions.

While still in its early stages, 3D printed electronics have the potential to revolutionize PCBA manufacturing for LED lighting applications. This technology could enable rapid prototyping and production of complex, multi-functional lighting fixtures that integrate PCB functionality directly into their structural components.

Conclusion

The importance of PCBs in efficient LED lighting design cannot be overstated. From thermal management and current distribution to enabling smart features and sustainable production, PCBs are at the heart of modern LED lighting systems. As PCBA manufacturing techniques continue to evolve, we can expect even more innovative and efficient LED lighting solutions that push the boundaries of performance, functionality, and design.

The ongoing advancements in PCB technology, coupled with the growing demand for energy-efficient lighting, ensure that the relationship between PCBs and LED lighting will continue to be a driving force in the lighting industry's evolution. As we look to the future, the integration of smart technologies, sustainable materials, and novel manufacturing processes will undoubtedly lead to exciting developments in LED lighting design, with PCBs playing a central role in these innovations.

Precision aluminum-backed PCB assembly for lighting OEMs | Ring PCB

Ring PCB Technology Co., Limited offers comprehensive one-stop PCB and PCBA services tailored for lighting OEMs. With 17 years of expertise, we deliver innovative and cost-effective solutions for various industries. Our advanced engineering capabilities include high-density stack-ups, smart manufacturing processes, and adherence to stringent quality standards. Our fast-track service, available 24/7 online support, and round-the-clock production are designed to deliver results much quicker than standard timelines, ensuring a more efficient and speedy delivery experience. Contact us at [email protected] to explore how our precision aluminum-backed PCB assemblies can enhance your LED lighting designs.

References

1. Johnson, M. (2022). Advanced PCB Design Techniques for LED Lighting Applications. Journal of Electronic Engineering, 45(3), 112-128.

2. Smith, A., & Brown, R. (2021). Thermal Management Strategies in LED Lighting PCBs. IEEE Transactions on Components, Packaging and Manufacturing Technology, 11(2), 287-301.

3. Lee, S., et al. (2023). Integration of IoT Capabilities in Modern LED Lighting Systems: PCB Design Considerations. Smart Lighting Technology Review, 7(1), 45-62.

4. Zhang, Y., & Liu, H. (2020). Sustainable Materials and Manufacturing Processes for LED Lighting PCBs. Green Electronics and Manufacturing, 5(4), 189-205.

5. Anderson, K. (2022). The Impact of PCB Design on LED Lighting Efficiency and Longevity. International Journal of Lighting Research and Technology, 54(2), 76-91.

Welcome to Ring PCB! Share your inquiry, and receive a tailored quotation!

Ring PCB, your trusted partner for PCB & PCBA Full Turnkey Solutions