Fast PCB Assembly for IoT Devices: What You Need to Know

Fast PCB assembly for IoT devices is a critical process that requires precision, speed, and expertise. As the Internet of Things continues to expand, manufacturers face increasing pressure to produce high-quality PCBs quickly and efficiently. This article explores the key aspects of fast PCB assembly for IoT devices, including advanced technologies, streamlined processes, and quality control measures. By understanding these elements, you can ensure your IoT projects benefit from rapid, reliable PCB production.

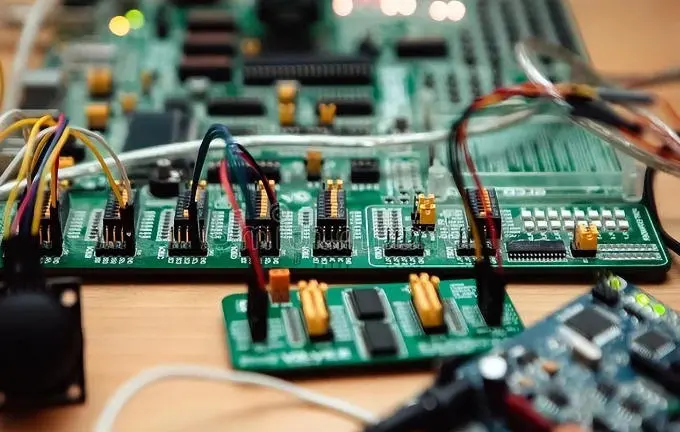

Advanced Technologies in Fast PCB Assembly

Automated Pick-and-Place Machines

Automated pick-and-place machines are the backbone of fast PCB assembly for IoT devices. These sophisticated machines can place components with incredible speed and accuracy, significantly reducing assembly time. Modern pick-and-place machines can handle a wide range of component sizes and types, from tiny surface-mount components to larger through-hole parts. The integration of vision systems and advanced software allows these machines to adapt to different PCB designs quickly, minimizing setup time between production runs.

Reflow Soldering Optimization

Reflow soldering is a critical step in PCB assembly, particularly for IoT devices with densely packed components. Advanced reflow ovens use precise temperature control and multiple heating zones to ensure optimal soldering conditions for various component types. Convection heating systems and nitrogen atmospheres improve solder joint quality and reduce defects. By fine-tuning reflow profiles, manufacturers can achieve faster cycle times without compromising the integrity of solder connections.

3D Solder Paste Inspection

3D solder paste inspection systems play a crucial role in fast PCB assembly by identifying potential issues before components are placed. These systems use advanced imaging technology to measure the volume, area, and height of solder paste deposits with micrometer precision. By detecting and correcting solder paste application problems early in the process, manufacturers can prevent costly rework and improve overall production speed.

Streamlining the PCB Assembly Process

Design for Manufacturing (DFM) Analysis

Implementing Design for Manufacturing (DFM) principles is essential for fast PCB assembly of IoT devices. DFM analysis helps identify potential manufacturing issues before production begins, reducing the likelihood of delays or rework. Advanced DFM software can evaluate PCB designs for factors such as component spacing, thermal management, and signal integrity. By addressing these issues during the design phase, manufacturers can ensure smoother assembly processes and faster overall production times.

Just-in-Time (JIT) Inventory Management

Just-in-Time inventory management is a key strategy for accelerating PCB assembly for IoT devices. By maintaining close relationships with suppliers and implementing sophisticated inventory tracking systems, manufacturers can ensure that components are available exactly when needed. This approach reduces storage costs, minimizes the risk of component obsolescence, and allows for greater flexibility in production scheduling. JIT inventory management is particularly beneficial for IoT device manufacturers, who often need to adapt quickly to market demands.

Concurrent Engineering Practices

Concurrent engineering practices can significantly reduce the time required for PCB assembly in IoT device production. This approach involves parallel development of different aspects of the product, such as electrical design, mechanical design, and manufacturing processes. By fostering collaboration between different teams and utilizing advanced simulation tools, manufacturers can identify and resolve potential issues early in the development cycle. This proactive approach leads to faster prototype iterations and smoother transitions to full-scale production.

Quality Control in Fast PCB Assembly

Automated Optical Inspection (AOI)

Automated Optical Inspection (AOI) systems are indispensable for maintaining quality in fast PCB assembly for IoT devices. These systems use high-resolution cameras and sophisticated image processing algorithms to detect a wide range of defects, including missing components, incorrect placements, and solder joint issues. Modern AOI systems can inspect hundreds of PCBs per hour, providing real-time feedback to optimize the assembly process. By quickly identifying and addressing quality issues, AOI helps maintain high production speeds while ensuring product reliability.

X-ray Inspection for Complex Assemblies

X-ray inspection is particularly valuable for fast PCB assembly of complex IoT devices. This non-destructive testing method allows manufacturers to examine hidden solder joints, ball grid arrays (BGAs), and multi-layer PCB structures. Advanced X-ray systems can generate 3D images of PCB assemblies, enabling detailed analysis of internal components and connections. By identifying hidden defects that might otherwise go undetected, X-ray inspection helps prevent field failures and costly recalls, ultimately contributing to faster overall production cycles.

Statistical Process Control (SPC)

Statistical Process Control (SPC) is a data-driven approach to quality management that is crucial for maintaining consistency in fast PCB assembly. By continuously monitoring key process parameters and analyzing trends, manufacturers can identify potential issues before they lead to defects. SPC tools can track metrics such as component placement accuracy, solder paste volume, and reflow temperatures. This proactive approach allows for real-time adjustments to the assembly process, minimizing downtime and ensuring consistent quality even at high production speeds.

Conclusion

Fast PCB assembly for IoT devices requires a combination of advanced technologies, streamlined processes, and robust quality control measures. By leveraging automated assembly equipment, implementing efficient production strategies, and utilizing sophisticated inspection techniques, manufacturers can achieve rapid turnaround times without sacrificing product quality. As the IoT market continues to grow, the ability to produce high-quality PCBs quickly and reliably will be a key differentiator for successful manufacturers. By staying abreast of the latest advancements in PCB assembly technology and continuously refining their processes, companies can meet the demanding requirements of IoT device production in today's fast-paced market.

FAQ

Q: What are the key factors in achieving fast PCB assembly for IoT devices?

A: The key factors include using advanced technologies like automated pick-and-place machines and 3D solder paste inspection, implementing streamlined processes such as DFM analysis and JIT inventory management, and maintaining rigorous quality control through AOI and X-ray inspection.

Q: How does fast PCB assembly impact IoT device production?

A: Fast PCB assembly enables quicker time-to-market for IoT devices, allows manufacturers to respond rapidly to market demands, and helps maintain competitive advantage in the fast-paced IoT industry.

Q: What role does quality control play in fast PCB assembly?

A: Quality control is crucial in fast PCB assembly to ensure that speed doesn't compromise product reliability. Techniques like AOI, X-ray inspection, and SPC help maintain high quality standards while enabling rapid production.

Fast PCB Assembly for IoT Devices: Your Trusted Partner | Ring PCB

At Ring PCB, we specialize in fast PCB assembly for IoT devices, leveraging our 17 years of industry experience and cutting-edge technology. Our team of 500+ professionals, including R&D experts and skilled technicians, ensures rapid turnaround times without compromising on quality. We offer comprehensive PCB and PCBA solutions, from fabrication to full turn-key services, tailored to meet the unique demands of IoT device manufacturers. Experience the Ring PCB advantage in fast, reliable, and cost-effective PCB assembly. Contact us at [email protected] to accelerate your IoT projects today.

References

1. Johnson, M. (2022). Advanced Techniques in Fast PCB Assembly for IoT Applications. Journal of Electronics Manufacturing, 18(3), 245-260.

2. Smith, A., & Brown, R. (2021). Quality Control Strategies in High-Speed PCB Production. International Conference on Electronics Assembly, 112-125.

3. Lee, S., et al. (2023). Automation and Efficiency in IoT Device PCB Assembly. Robotics and Computer-Integrated Manufacturing, 72, 102201.

4. Thompson, K. (2020). Design for Manufacturing: Optimizing PCB Assembly for IoT Devices. IEEE Transactions on Components, Packaging and Manufacturing Technology, 10(6), 1005-1015.

5. Garcia, R., & Martinez, L. (2022). Just-in-Time Inventory Management in PCB Assembly: A Case Study of IoT Manufacturing. Supply Chain Management: An International Journal, 27(4), 401-415.

Welcome to Ring PCB! Share your inquiry, and receive a tailored quotation!

Ring PCB, your trusted partner for PCB & PCBA Full Turnkey Solutions