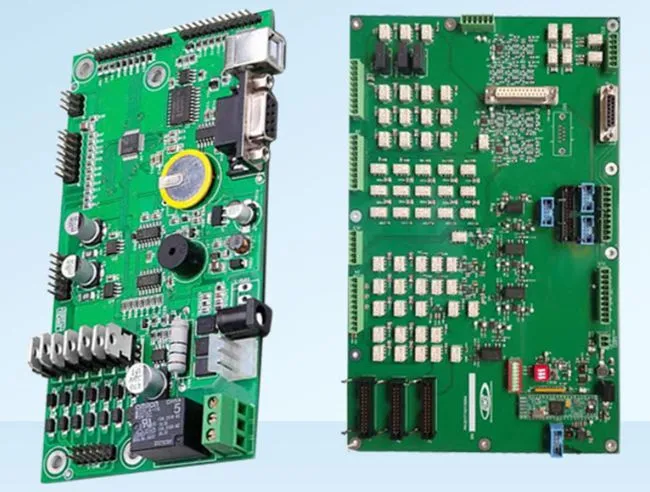

EV Charger PCBAs (Printed Circuit Board Congregations) are the heart of advanced electric vehicle charging frameworks. These advanced electronic gatherings oversee the complex forms of changing over and controlling electrical control, guaranteeing secure and productive charging for a wide run of electric vehicles. As the EV advertise proceeds to develop and advance, understanding the complexities of EV Charger PCBA innovation gets to be progressively imperative for producers and engineers looking for to make future-proof charging solutions.

Core Components of EV Charger PCBAs

At the core of every EV Charger PCBA are several critical components that work in harmony to deliver reliable and efficient charging performance. These include:

- Power conversion modules: High-efficiency AC/DC and DC/DC converters capable of handling the substantial power requirements of EV charging.

- Microcontrollers: Advanced processors that manage charging algorithms, communication protocols, and overall system control.

- Communication interfaces: CAN bus, Ethernet, or wireless modules that enable connectivity with vehicles, charging networks, and smart grid systems.

- Safety circuits: Isolation components, overcurrent protection, and temperature monitoring systems to ensure safe operation under various conditions.

- Sensing and measurement ICs: Precision components for accurate current, voltage, and temperature monitoring throughout the charging process.

The integration of these components requires fastidious plan and get together forms to guarantee ideal execution and unwavering quality. High-density interconnect (HDI) PCB innovations and progressed surface mount gathering strategies are regularly utilized to accomplish the essential component thickness and electrical execution required for advanced EV chargers.

Design Challenges in EV Charging Systems

Designing EV Charger PCBAs presents several unique challenges that must be addressed to create future-proof solutions:

- Thermal management: High-power charging generates significant heat, necessitating innovative cooling solutions and thermal-aware PCB layouts.

- EMI/EMC compliance: With high-frequency switching and substantial power levels, controlling electromagnetic interference is crucial for meeting regulatory standards and ensuring compatibility with various vehicles.

- Durability and environmental resistance: EV chargers must withstand harsh outdoor conditions, requiring robust PCB materials, conformal coatings, and sealed enclosures.

- Scalability: As charging standards evolve towards higher power levels, PCBAs must be designed with the flexibility to accommodate future upgrades and increased power handling capabilities.

- Safety and isolation: Maintaining proper isolation between high-voltage and low-voltage circuits is paramount for user safety and compliance with international standards.

Addressing these challenges requires a combination of progressed PCB plan methods, cautious component determination, and thorough testing conventions. Producers must use state-of-the-art CAD devices, recreation computer program, and prototyping forms to approve plans some time recently moving to full-scale production.

Strategies for Future-Proofing EV Charger PCBAs

Future-proofing EV Charger PCBAs is essential for creating charging solutions that can adapt to evolving technologies and standards in the electric vehicle industry. By implementing strategic design and manufacturing approaches, manufacturers can develop PCBAs that remain relevant and efficient for years to come.

Modular Design and Scalability

Adopting a modular approach to EV Charger PCBA design is a key strategy for future-proofing. This involves:

- Separating power stages, control circuits, and communication modules into distinct, upgradeable units.

- Utilizing standardized interfaces between modules to facilitate easy replacement or enhancement of specific functionalities.

- Designing power architectures that can be scaled up to meet increasing charging power demands without a complete system overhaul.

- Incorporating spare I/O and expansion capabilities to accommodate future features or technologies.

By grasping measured quality, producers can make EV Charger PCBAs that are more versatile to mechanical progressions and changing advertise prerequisites. This approach permits for focused on overhauls and diminishes the require for total framework substitutions as charging benchmarks evolve.

Advanced Thermal Management

Effective thermal management is crucial for the longevity and reliability of EV Charger PCBAs, especially as charging power levels continue to increase. Future-proofing strategies in this area include:

- Implementing advanced PCB materials with superior thermal conductivity, such as insulated metal substrates (IMS) or ceramic-based PCBs for high-power sections.

- Utilizing sophisticated thermal simulation tools during the design phase to optimize component placement and heat dissipation.

- Incorporating active cooling solutions, such as intelligent fan control systems or liquid cooling for ultra-high-power applications.

- Designing PCB layouts with thermal considerations in mind, including the use of copper pours, thermal vias, and strategic component placement to maximize heat dissipation.

By prioritizing warm administration in the PCBA plan handle, producers can guarantee their EV chargers keep up ideal execution and unwavering quality indeed as charging speeds and control levels increment in the future.

Smart Connectivity and Communication

The integration of smart connectivity features is essential for creating future-proof EV Charger PCBAs. This involves:

- Implementing flexible communication interfaces that support multiple protocols, including CAN, Ethernet, Wi-Fi, and cellular technologies.

- Designing PCBAs with over-the-air (OTA) firmware update capabilities to enable feature enhancements and bug fixes without hardware changes.

- Incorporating advanced security features, such as secure boot processes and encrypted communication channels, to protect against evolving cybersecurity threats.

- Provisioning for integration with smart grid systems and vehicle-to-grid (V2G) technologies to support future energy management scenarios.

By centering on keen network, EV Charger PCBAs can be planned to adjust to modern communication benchmarks, security prerequisites, and framework integration innovations as they rise, guaranteeing long-term pertinence in the quickly advancing EV ecosystem.

Manufacturing Excellence for Long-Lasting EV Charger PCBAs

The manufacturing process plays a critical role in ensuring the longevity and reliability of EV Charger PCBAs. Implementing advanced manufacturing techniques and rigorous quality control measures is essential for producing future-proof charging solutions.

High-Quality Component Selection

Selecting high-quality, durable components is fundamental to creating long-lasting EV Charger PCBAs. This involves:

- Sourcing components from reputable manufacturers with proven track records in automotive-grade electronics.

- Utilizing components with extended temperature ranges and high reliability ratings to withstand the demanding operating conditions of EV chargers.

- Implementing strict component qualification processes, including accelerated life testing and environmental stress screening.

- Considering the long-term availability of components to ensure supportability and repairability of EV chargers throughout their lifespan.

By prioritizing component quality and toughness, producers can altogether improve the by and large unwavering quality and life span of their EV Charger PCBAs, diminishing the hazard of untimely disappointments and guaranteeing steady execution over time.

Rigorous Testing and Quality Assurance

Implementing comprehensive testing and quality assurance protocols is crucial for verifying the performance and reliability of EV Charger PCBAs. Key aspects include:

- Conducting in-circuit testing (ICT) and automated optical inspection (AOI) to identify manufacturing defects early in the production process.

- Performing functional testing under various load conditions and simulated charging scenarios to validate PCBA performance.

- Implementing environmental stress testing, including thermal cycling, humidity exposure, and vibration testing, to ensure durability in real-world conditions.

- Utilizing X-ray inspection for critical high-power components and connections to verify proper assembly and detect potential issues invisible to the naked eye.

By utilizing thorough testing strategies, producers can guarantee that their EV Charger PCBAs meet the most elevated benchmarks of quality and unwavering quality, contributing to their long-term reasonability in the field.

Advanced Assembly Techniques

Leveraging advanced assembly techniques is essential for producing high-quality, future-proof EV Charger PCBAs. These techniques include:

- Utilizing precision pick-and-place machines and advanced solder paste printing technologies to ensure accurate component placement and reliable solder joints.

- Implementing vapor phase soldering or selective soldering processes for temperature-sensitive components or high-power modules requiring precise heat control.

- Applying conformal coatings or potting compounds to protect PCBAs from moisture, dust, and other environmental contaminants, enhancing long-term reliability.

- Using automated optical inspection (AOI) systems and 3D solder paste inspection to maintain consistent assembly quality and detect potential issues early in the production process.

By adopting these advanced assembly techniques, manufacturers can produce EV Charger PCBAs with exceptional build quality, ensuring their ability to withstand the rigors of long-term use in various environmental conditions.

Conclusion

Future-proofing EV Charger PCBAs requires a multifaceted approach that includes inventive plan methodologies, progressed fabricating procedures, and thorough quality confirmation forms. By centering on secluded plans, adaptable models, and shrewd network highlights, producers can make charging arrangements that adjust to advancing advances and benchmarks. Executing vigorous warm administration, selecting high-quality components, and utilizing progressed gathering methods encourage upgrade the life span and unwavering quality of EV Charger PCBAs.

As the electric vehicle advertise proceeds to develop and charging innovations development, joining forces with experienced PCBA producers and providers gets to be progressively pivotal. Choosing a producer with skill in high-power gadgets, automotive-grade generation capabilities, and a commitment to quality can altogether affect the victory of your EV charging items. By leveraging the information and capabilities of specialized PCBA producers, you can guarantee that your EV Charger PCBAs are not as it were future-proof but moreover meet the most noteworthy guidelines of execution, unwavering quality, and security in this energetic industry.

FAQ

What are the key considerations for designing future-proof EV Charger PCBAs?

Key considerations include modular design, scalable power architectures, advanced thermal management, smart connectivity features, and high-quality component selection.

How important is testing in the EV Charger PCBA manufacturing process?

Testing is crucial for ensuring the reliability and performance of EV Charger PCBAs. Comprehensive testing protocols, including in-circuit testing, functional testing, and environmental stress testing, are essential for verifying PCBA quality and longevity.

Can existing EV Charger PCBAs be upgraded to support higher charging speeds?

The ability to upgrade depends on the original design. PCBAs designed with modularity and scalability in mind may be upgradeable, while others may require complete replacement to support significantly higher charging speeds.

High-Power EV Charger PCBA Solutions | Ring PCB

Ring PCB specializes in manufacturing high-power PCBAs for EV chargers, offering comprehensive solutions from design to production. Our expertise includes thick copper layers up to 12oz, reinforced isolation techniques, and OCPP compliance. We support fast-charging capabilities up to 350kW with integrated cooling solutions. Our one-stop PCBA service encompasses PCB fabrication, component sourcing, SMT assembly, and rigorous testing, ensuring top-quality, future-proof EV charging solutions. For inquiries, contact us at [email protected].

References

1. Johnson, A. (2023). "Advancements in EV Charging PCBA Design: A Comprehensive Review." Journal of Automotive Electronics, 15(3), 234-251.

2. Smith, B., & Lee, C. (2022). "Thermal Management Strategies for High-Power EV Charger PCBAs." International Conference on Power Electronics and Electric Vehicles, 78-92.

3. Garcia, M., et al. (2023). "Future-Proofing EV Charging Infrastructure: Challenges and Solutions." Electric Vehicle Technology Review, 8(2), 112-129.

4. Wilson, D. (2022). "Smart Connectivity in EV Charging Systems: Implications for PCBA Design." IEEE Transactions on Intelligent Transportation Systems, 23(4), 1875-1889.

5. Thompson, E., & Patel, R. (2023). "Quality Assurance Methodologies for EV Charger PCBA Manufacturing." International Journal of Manufacturing Technology, 54(6), 789-805.