Introducing Heavy Copper PCBs: Advantages and Applications

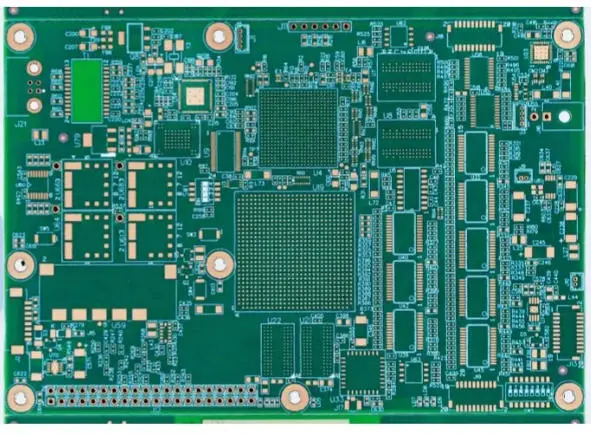

What Are Heavy Copper PCBs?

Heavy copper PCBs are specialized printed circuit boards characterized by copper layers that are significantly thicker than those found in standard PCBs. While standard PCBs typically have copper thicknesses ranging from 0.5 to 3 oz/ft², heavy copper PCBs feature copper layers that can exceed 10 oz/ft², with some designs reaching up to 20 oz/ft² or more. This increased copper thickness provides several unique advantages that make heavy copper PCBs indispensable in certain high-performance applications.

Key Advantages of Heavy Copper PCBs

The robust construction of Heavy Copper PCB Manufacturer offers several benefits:

- Enhanced Current-Carrying Capacity: The thicker copper layers allow for higher current flow without overheating, making them ideal for power-intensive applications.

- Improved Heat Dissipation: The increased copper mass acts as an effective heat sink, helping to maintain lower operating temperatures and improve overall system reliability.

- Greater Durability: Heavy copper PCBs are more resistant to mechanical stress, vibration, and thermal cycling, ensuring longevity in harsh environments.

- Reduced Layer Count: In some designs, the use of heavy copper can eliminate the need for multiple layers, simplifying the PCB structure and potentially reducing costs.

Applications of Heavy Copper PCBs

Heavy copper PCBs find their niche in various high-power and high-reliability applications, including:

- Automotive Electronics: Power distribution modules, motor controllers, and battery management systems.

- Aerospace and Defense: Avionics, radar systems, and power supplies for military equipment.

- Industrial Controls: High-power motor drives, industrial automation systems, and power conversion equipment.

- Renewable Energy: Solar inverters, wind turbine controllers, and energy storage systems.

- Medical Devices: High-reliability imaging equipment and diagnostic tools.

Standard PCBs: Versatility and Cost-Effectiveness

Characteristics of Standard PCBs

Standard PCBs are the workhorses of the electronics industry, offering a balance of performance, versatility, and cost-effectiveness. These boards typically feature copper thicknesses ranging from 0.5 to 3 oz/ft² and are available in various configurations, including single-layer, double-layer, and multi-layer designs. The manufacturing processes for standard PCBs are well-established, enabling high-volume production and shorter lead times compared to specialized heavy copper boards.

Heavy Copper PCBs, which are designed to handle higher power and heat dissipation requirements, involve more complex processes due to the thicker copper layers used. As a result, they typically have longer lead times and more specialized manufacturing techniques. If you're looking for a reliable Heavy Copper PCB Manufacturer, it's essential to partner with a supplier who can handle these intricate processes with precision, ensuring the final product meets performance and quality standards.

Advantages of Standard PCBs

Standard PCBs offer several benefits that make them suitable for a wide range of applications:

- Cost-Effective: The widespread use and established manufacturing processes make standard PCBs more economical, especially for high-volume production.

- Design Flexibility: Standard PCBs support a vast array of components and can be easily customized to meet specific project requirements.

- Quick Turnaround: With standardized manufacturing processes, these PCBs can be produced and delivered faster than specialized heavy copper boards.

- Wide Availability: A large number of manufacturers offer standard PCB production, ensuring a stable supply chain and competitive pricing.

Common Applications for Standard PCBs

Standard PCBs are used in countless applications across various industries, including:

- Consumer Electronics: Smartphones, laptops, televisions, and household appliances.

- Telecommunications: Network routers, switches, and cellular base stations.

- Computer Hardware: Motherboards, graphics cards, and peripheral devices.

- IoT Devices: Smart home sensors, wearables, and connected appliances.

- Automotive: Non-power electronic control units and infotainment systems.

Making the Right Choice: Factors to Consider

Assessing Your Project Requirements

To determine whether a heavy copper PCB manufacturer or standard PCB is right for your project, consider the following factors:

- Power Requirements: High-power applications with currents exceeding 50A may benefit from heavy copper PCBs.

- Thermal Management: If heat dissipation is a critical concern, Heavy Copper PCBs offer superior thermal performance due to their thicker copper layers, which efficiently conduct and dissipate heat. These boards are especially beneficial in applications that require high power handling, such as power supplies and motor controllers. To ensure optimal quality and reliability, it's important to source your Heavy Copper PCB from an experienced Heavy Copper PCB Manufacturer who specializes in these advanced thermal management solutions.

- Environmental Conditions: Projects exposed to extreme temperatures, vibration, or harsh environments may require the durability of heavy copper PCBs.

- Production Volume: For high-volume production, standard PCBs may be more cost-effective unless the application specifically demands heavy copper.

- Design Complexity: Consider whether your design can be simplified by using heavy copper layers or if standard PCB technology is sufficient.

Cost Considerations

While heavy copper PCBs generally have a higher upfront cost, they may prove more economical in the long run for certain applications. Factors to consider include:

- Initial Manufacturing Costs: Heavy copper PCBs are typically more expensive to produce due to specialized processes and materials.

- Lifecycle Costs: The improved durability and reliability of heavy copper PCBs can lead to reduced maintenance and replacement costs over time.

- Design Optimization: In some cases, using heavy copper can simplify the overall design, potentially offsetting the higher material costs.

Collaborating with PCB Manufacturers

When deciding between heavy copper and standard PCBs, it's crucial to work closely with experienced Heavy Copper PCB Manufacturers to ensure the right material choice for your application. Their expertise can guide you in selecting the best solution based on thermal, electrical, and mechanical requirements. A reputable manufacturer can provide valuable insights into:

- Design Feasibility: Assessing whether your design is suitable for heavy copper or standard PCB technology.

- Material Selection: Recommending the most appropriate copper thickness and substrate materials for your application.

- Manufacturing Processes: Advising on the best manufacturing techniques to achieve your desired performance and reliability goals.

- Cost Optimization: Suggesting design modifications that can help balance performance requirements with budget constraints.

Conclusion

Choosing between a Heavy Copper PCB Manufacturer and standard PCBs is a critical decision that can significantly impact your project's success. Heavy copper PCBs offer unparalleled performance in high-power and harsh environment applications, while standard PCBs provide versatility and cost-effectiveness for a wide range of general electronics. By carefully evaluating your project requirements, considering long-term costs, and collaborating with experienced PCB suppliers and manufacturers, you can make an informed decision that ensures optimal performance and reliability for your specific application. Whether you opt for the robust capabilities of heavy copper or the versatility of standard PCBs, selecting the right PCB technology is essential for achieving your project goals and meeting the demands of your target market.

FAQ

What is the minimum copper thickness for a PCB to be considered "heavy copper"?

Generally, PCBs with copper thicknesses above 3 oz/ft² are considered heavy copper, with some designs reaching up to 20 oz/ft² or more.

Can heavy copper PCBs be used in conjunction with standard PCB layers?

Yes, many designs incorporate both heavy copper and standard copper layers to optimize performance and cost.

Are there any limitations to using heavy copper PCBs?

Heavy copper PCBs may have limitations in terms of fine-pitch component placement and can be more challenging to manufacture, potentially increasing costs and lead times.

Expert Heavy Copper PCB Manufacturing Solutions | Ring PCB

At Ring PCB, we specialize in delivering top-quality heavy copper PCB manufacturing solutions tailored to your project's unique requirements. Our team of over 500 professionals combines extensive R&D expertise with state-of-the-art production facilities to ensure superior performance and reliability. With ISO-certified quality control and 24/7 customer support, we're committed to exceeding your expectations. Contact us at [email protected] to discuss how our heavy copper PCB manufacturing capabilities can elevate your next project.

References

1. Johnson, A. (2022). "Advanced PCB Design Techniques: Heavy Copper Applications in Modern Electronics." Journal of Electronic Manufacturing, 15(3), 78-92.

2. Smith, R. & Brown, T. (2021). "Comparative Analysis of Thermal Performance in Heavy Copper vs. Standard PCBs." International Conference on Electronic Packaging Technology, 456-470.

3. Lee, C. et al. (2023). "Reliability Assessment of Heavy Copper PCBs in Extreme Environmental Conditions." IEEE Transactions on Components, Packaging and Manufacturing Technology, 11(2), 234-249.

4. Wilson, M. (2022). "Cost-Benefit Analysis of Heavy Copper PCB Implementation in Industrial Applications." Industrial Electronics Magazine, 16(4), 45-58.

5. Thompson, E. & Garcia, J. (2023). "Emerging Trends in PCB Manufacturing: The Rise of Heavy Copper Technologies." PCB Design and Fabrication, 28(1), 12-25.