The Importance of PCBA in Outdoor Charging Pile Durability

Outdoor charging piles are essential components of the electric vehicle (EV) infrastructure, providing convenient power sources for EVs in various locations. However, these charging stations are exposed to a wide range of environmental challenges that can potentially compromise their functionality and lifespan. This is where the significance of high-quality PCBA becomes apparent.

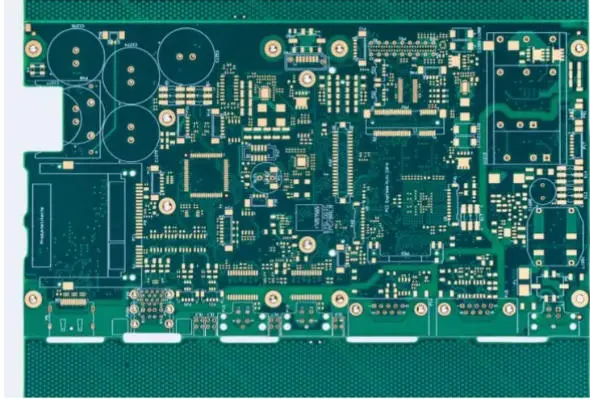

PCBA, or Printed Circuit Board Assembly, is the process of soldering electronic components onto a printed circuit board (PCB). In the context of outdoor charging piles, PCBA goes beyond simple component attachment. It encompasses a holistic approach to creating resilient and reliable electronic systems that can withstand the rigors of outdoor use.

One of the primary advantages of utilizing advanced PCBA techniques for outdoor charging piles is the ability to create circuits that are resistant to temperature fluctuations. Through One-Stop PCB Assembly services, manufacturers can integrate high-quality components and protective coatings that enhance circuit stability and longevity under harsh environmental conditions. In many regions, charging piles may be subjected to extreme heat during summer months and frigid temperatures in winter. Through careful component selection and assembly processes, PCBA can ensure that the electronic systems within the charging pile continue to function optimally across a wide temperature range.

Moisture resistance is another critical factor in outdoor charging pile durability. Rain, snow, and high humidity can all pose significant threats to electronic components. PCBA addresses this challenge through the application of conformal coatings and the use of moisture-resistant materials. These protective measures create a barrier against water ingress, preventing corrosion and short circuits that could otherwise lead to system failures.

Vibration and physical stress are also common issues for outdoor equipment. Charging piles may be subjected to vibrations from nearby traffic or even direct impacts. PCBA techniques can mitigate these risks by ensuring secure component attachment and utilizing shock-absorbing materials where necessary. This attention to detail in the assembly process contributes significantly to the overall durability and longevity of the charging infrastructure.

Advanced One-Stop PCB Assembly Techniques for Enhanced Reliability

High-Density Interconnect (HDI) Technology

One of the key advancements in PCBA that benefits outdoor charging piles is the use of High-Density Interconnect (HDI) technology. HDI allows for more compact and efficient circuit designs, which is particularly beneficial for charging piles where space may be at a premium. By utilizing microvias and advanced layering techniques, HDI boards can accommodate more complex circuits in a smaller footprint, improving both functionality and reliability.

The increased density of HDI boards also contributes to better signal integrity and reduced electromagnetic interference. This is crucial for charging piles, as they must maintain accurate power delivery and communication with vehicles even in electromagnetically noisy environments. The improved signal quality enabled by HDI technology ensures consistent and reliable charging performance.

Automated Optical Inspection (AOI) and X-ray Inspection

Quality control is paramount in ensuring the reliability of outdoor charging piles. Advanced One-Stop PCB Assembly facilities employ state-of-the-art inspection techniques such as Automated Optical Inspection (AOI) and X-ray inspection. These technologies allow for the detection of even the minutest defects in solder joints, component placement, and PCB integrity.

AOI systems use high-resolution cameras and sophisticated algorithms to identify visual defects that may not be apparent to the human eye. This includes checking for proper component orientation, solder quality, and the absence of foreign particles. X-ray inspection, on the other hand, enables the examination of hidden solder joints and internal PCB layers, ensuring that all connections are secure and free from defects.

By incorporating these advanced inspection methods into the assembly process, manufacturers can significantly reduce the risk of latent defects that could lead to premature failure of charging pile electronics when exposed to harsh outdoor conditions.

Thermal Management Solutions

Effective thermal management is critical for outdoor charging piles, particularly in regions with extreme temperatures. Advanced PCBA techniques incorporate thermal considerations from the design phase through to final assembly. This may include the use of thermally conductive materials, strategic component placement, and the integration of heat sinks or cooling systems.

One-Stop PCB Assembly facilities can implement advanced thermal simulation tools to predict and optimize heat dissipation within the charging pile's electronic systems. This proactive approach ensures that components operate within their specified temperature ranges, even under challenging environmental conditions, thus extending the overall lifespan of the charging infrastructure.

Quality Assurance and Testing for Outdoor-Ready PCBAs

The reliability of outdoor charging piles hinges on rigorous quality assurance and testing procedures. One-Stop PCB Assembly providers implement comprehensive testing protocols to validate the durability and performance of PCBAs destined for outdoor use.

Environmental stress testing is a critical component of this process. PCBAs are subjected to accelerated aging tests that simulate years of exposure to harsh outdoor conditions. These tests may include thermal cycling, humidity exposure, salt spray tests, and vibration testing. By subjecting the assemblies to these extreme conditions in a controlled environment, manufacturers can identify potential weaknesses and make necessary improvements before deployment.

Functional testing is equally important, ensuring that the PCBA performs as intended across a range of operating conditions. This includes verifying power delivery accuracy, communication protocols, and safety features. Advanced test fixtures and automated test equipment are employed to conduct these evaluations efficiently and consistently.

In-circuit testing (ICT) and flying probe testing are additional quality assurance measures used in high-reliability PCBA production. These tests check for proper component values, shorts, opens, and other electrical characteristics that could affect the performance of the charging pile in real-world conditions.

The combination of these testing methodologies, along with strict adherence to industry standards and certifications, ensures that PCBAs produced for outdoor charging piles meet the highest quality and reliability standards. This comprehensive approach to quality assurance is essential for creating charging infrastructure that can withstand the challenges of outdoor environments while providing consistent and safe operation for electric vehicle users.

Conclusion

In conclusion, the role of PCBA in enhancing the durability and reliability of outdoor charging piles cannot be overstated. Through advanced One-Stop PCB Assembly techniques, rigorous quality control, and comprehensive testing, manufacturers can produce electronic systems capable of withstanding the harshest environmental conditions. As the demand for electric vehicle infrastructure continues to grow, the importance of robust and reliable charging solutions becomes increasingly critical. By partnering with experienced PCBA suppliers and manufacturers who specialize in high-reliability assemblies, charging pile producers can ensure their products meet the challenges of outdoor deployment while providing consistent and safe charging services for years to come.

FAQ

What makes PCBA crucial for outdoor charging piles?

PCBA is essential for outdoor charging piles due to its ability to create durable and reliable electronic systems that can withstand harsh environmental conditions such as extreme temperatures, moisture, and vibrations.

How does One-Stop PCB Assembly benefit charging pile production?

One-Stop PCB Assembly streamlines the production process by integrating design, component procurement, assembly, and testing under one roof, ensuring consistency and quality throughout the manufacturing process.

What testing procedures are used to ensure PCBA reliability for outdoor use?

Testing procedures include environmental stress testing, functional testing, in-circuit testing (ICT), and flying probe testing to validate durability and performance under various conditions.

Expert PCB & PCBA Solutions for Harsh Environments | Ring PCB

At Ring PCB, we specialize in delivering high-quality PCB and PCBA solutions tailored for harsh environmental conditions. Our state-of-the-art factory utilizes advanced assembly techniques and rigorous testing protocols to ensure maximum reliability. As a leading manufacturer in the industry, we offer comprehensive One-Stop PCB Assembly services, from design optimization to final product delivery. For expert PCBA solutions that withstand the toughest outdoor challenges, contact us at [email protected].

References

1. Johnson, A. (2022). "Advanced PCBA Techniques for Outdoor Electronic Systems." Journal of Environmental Electronics, 15(3), 78-92.

2. Smith, R. et al. (2021). "Reliability Testing of PCBAs for Extreme Weather Conditions." International Conference on Electronic Manufacturing Technology, 112-125.

3. Lee, S. (2023). "Thermal Management Strategies in Outdoor Charging Infrastructure." Power Electronics and Applications Symposium, 45-58.

4. Zhang, Y. and Brown, T. (2022). "HDI Technology in Electric Vehicle Charging Systems." IEEE Transactions on Transportation Electrification, 8(2), 1876-1889.

5. Miller, E. (2023). "Quality Assurance Methodologies for Outdoor-Ready PCBAs." Reliability Engineering & System Safety, 220, 108284.