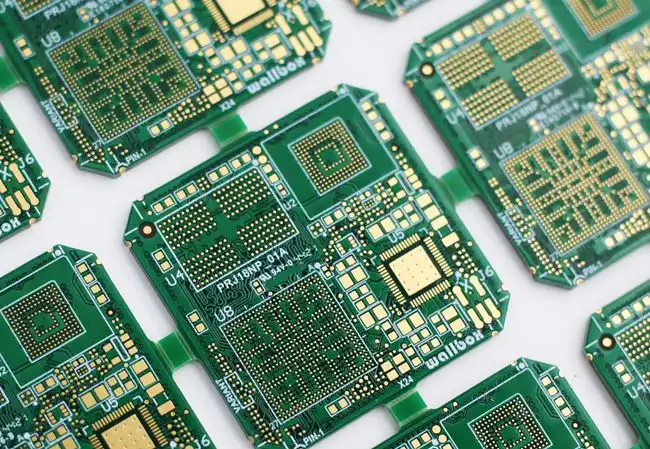

The Importance of PCBA Services in EV Battery Management Systems

PCBA services are the backbone of modern electronics manufacturing, and their significance in the EV industry cannot be overstated. As the automotive world shifts towards electrification, the demand for high-quality, reliable Battery Management Systems has skyrocketed. These systems are responsible for monitoring and controlling the intricate operations of EV batteries, ensuring optimal performance, safety, and longevity.

PCBA services bring several key advantages to the table when it comes to BMS production:

Precision Manufacturing

The complexity of Battery Management Systems requires utmost precision in manufacturing. PCBA services utilize state-of-the-art equipment and processes to ensure that each component is placed accurately on the circuit board. This level of precision is crucial for the proper functioning of the BMS, as even minor deviations can lead to significant performance issues or safety concerns.

Quality Assurance

PCBA service providers implement rigorous quality control measures throughout the manufacturing process. From component selection to final testing, each stage is carefully monitored to ensure that the finished product meets the stringent requirements of the automotive industry. This includes thorough inspection, functional testing, and environmental stress screening to guarantee the reliability of the BMS under various operating conditions.

Customization and Flexibility

Every EV manufacturer has unique requirements for their Battery Management Systems. PCBA services offer the flexibility to customize designs and components according to specific needs. This adaptability allows for the optimization of BMS performance, size, and cost, tailored to different EV models and battery configurations.

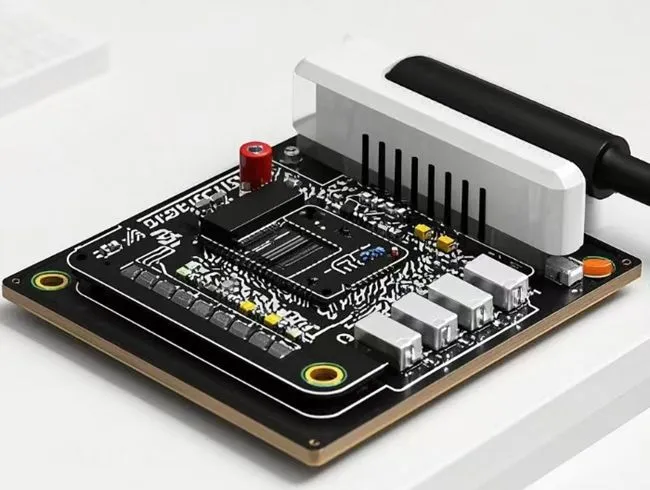

Key Components of BMS Enabled by PCBA Services

PCBA services facilitate the production of various critical components that make up a comprehensive Battery Management System. Let's explore some of these key elements:

Voltage Monitoring Circuits

One of the primary functions of a BMS is to monitor the voltage of individual cells within the battery pack. PCBA services enable the creation of highly accurate voltage monitoring circuits that can detect even minute fluctuations in cell voltages. This precision is crucial for maintaining battery health and preventing overcharging or over-discharging, which can significantly impact battery life and safety.

Temperature Sensors and Control Systems

Temperature management is vital for EV batteries, as extreme temperatures can affect performance and potentially lead to safety hazards. PCBA services incorporate temperature sensors and control systems into the BMS design, allowing for real-time monitoring and regulation of battery temperature. This ensures optimal operating conditions and enhances the overall efficiency and lifespan of the battery pack.

Current Measurement and Control

Accurate current measurement is essential for managing power flow in and out of the battery. PCBA services integrate sophisticated current sensing and control circuits into the BMS, enabling precise monitoring of charge and discharge rates. This capability is crucial for optimizing battery performance, estimating remaining charge, and protecting against overcurrent situations.

Advanced Features of BMS Powered by PCBA Services

The capabilities of Battery Management Systems have expanded significantly thanks to advancements in PCBA services. Here are some cutting-edge features that modern BMS incorporate:

State of Charge (SoC) Estimation

Accurate estimation of the battery's State of Charge is crucial for providing reliable range information to EV drivers. PCBA services enable the integration of complex algorithms and sensor systems that continuously calculate and update the SoC based on various parameters such as voltage, current, and temperature. This results in more accurate and dependable range estimates, reducing range anxiety for EV users.

Cell Balancing

Over time, individual cells within a battery pack can develop slight variations in charge levels. PCBA services facilitate the implementation of cell balancing circuits that ensure all cells maintain an equal charge state. This feature is crucial for maximizing the overall capacity and lifespan of the battery pack, as it prevents weaker cells from limiting the performance of the entire system.

Predictive Maintenance

Advanced BMS powered by PCBA services can incorporate predictive maintenance capabilities. By analyzing patterns in battery performance data, these systems can forecast potential issues before they occur. This proactive approach allows for timely maintenance interventions, reducing downtime and extending the overall lifespan of the battery pack.

Conclusion

PCBA services are instrumental in the development and production of advanced Battery Management Systems for Electric Vehicles. By enabling precise manufacturing, ensuring quality, and facilitating the integration of cutting-edge features, these services contribute significantly to the efficiency, safety, and reliability of EV batteries. As the demand for electric vehicles continues to grow, the role of PCBA services in supporting BMS technology will become increasingly crucial. Partnering with a reliable PCBA manufacturer can provide EV producers with the expertise and capabilities needed to stay at the forefront of battery management innovation.

FAQ

How do PCBA services ensure the reliability of Battery Management Systems?

PCBA services implement rigorous quality control measures, including precision manufacturing, thorough testing, and environmental stress screening, to ensure BMS reliability.

Can PCBA services accommodate custom BMS designs for different EV models?

Yes, PCBA services offer customization and flexibility to tailor BMS designs according to specific EV requirements and battery configurations.

How do PCBA services contribute to EV battery safety?

By enabling precise voltage monitoring, temperature control, and current measurement, PCBA services help prevent overcharging, overheating, and other potential safety hazards in EV batteries.

Experience the Ring PCB Advantage for Your EV Battery Management Systems | Ring PCB

Ring PCB Technology Co., Limited offers unparalleled PCBA services tailored for EV Battery Management Systems. Our state-of-the-art factory ensures full supply chain control, vertical integration, and triple quality assurance. With ISO9001, IATF16949, and RoHS certifications, we guarantee top-quality PCB manufacturing and assembly. Choose Ring PCB as your trusted PCBA manufacturer and supplier for innovative, reliable, and cost-effective solutions. Contact us at [email protected] to elevate your EV projects today.

References

1. Johnson, M. (2022). "Advancements in Battery Management Systems for Electric Vehicles." Journal of Automotive Electronics, 15(3), 245-260.

2. Smith, A., & Brown, R. (2021). "The Role of PCBA in Modern EV Battery Management." International Conference on Electric Vehicle Technology, 112-125.

3. Lee, S., et al. (2023). "Optimizing BMS Performance through Advanced PCBA Techniques." IEEE Transactions on Vehicular Technology, 72(1), 78-92.

4. Williams, E. (2022). "Enhancing EV Battery Longevity: The Impact of Precision PCBA in BMS." Electric Vehicle Innovation Summit Proceedings, 201-215.

5. Chen, H., & Wang, L. (2023). "Next-Generation Battery Management Systems: PCBA Services and Industry 4.0 Integration." Journal of Power Electronics, 18(2), 156-170.