How Self-Driving Cars Work: Tesla’s Robotaxi and the Role of PCBA Technology

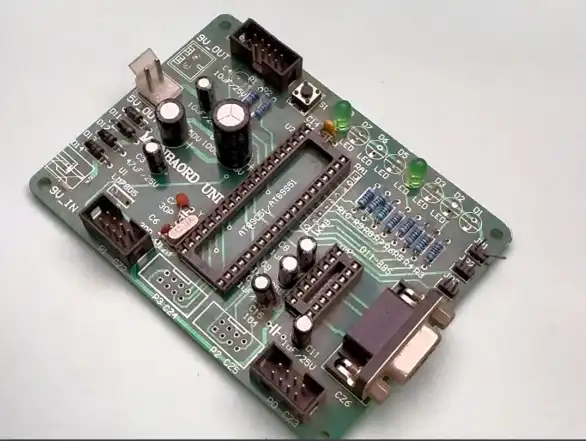

Self-driving cars, particularly Tesla's Robotaxi, represent a revolutionary leap in automotive technology. These vehicles rely on a complex network of sensors, cameras, and advanced computing systems to navigate roads autonomously. At the heart of this technology lies the power supply PCBA (Printed Circuit Board Assembly), which provides the stable and efficient electrical power needed to run these sophisticated systems. The PCBA manages power distribution, ensures signal integrity, and supports the high-performance processors that make split-second decisions based on real-time data. As Tesla pushes the boundaries of autonomous driving with its Robotaxi concept, the role of power supply PCBAs becomes increasingly crucial in enabling safe, reliable, and efficient self-driving experiences.

The Evolution of Self-Driving Technology in Tesla Vehicles

Tesla has been at the forefront of autonomous driving technology, continuously refining its systems to achieve higher levels of self-driving capability. The company's approach combines advanced hardware with sophisticated software algorithms to create a comprehensive autonomous driving solution.

Tesla's Autopilot System: The Foundation of Self-Driving

Tesla's journey into self-driving technology began with the introduction of its Autopilot system. This advanced driver-assistance system (ADAS) uses a combination of cameras, ultrasonic sensors, and radar to perceive the vehicle's environment. The power supply PCBA plays a critical role in ensuring these sensors receive consistent and clean power, enabling them to function optimally under various conditions.

As Tesla has iterated on its Autopilot system, the demands on the power supply PCBA have increased. Modern versions of Autopilot require more processing power to handle the vast amounts of data generated by the vehicle's sensors. This has led to the development of more sophisticated power management systems within the PCBA, capable of delivering stable power to multiple high-performance components simultaneously.

Full Self-Driving (FSD) Capability: Pushing the Boundaries

Building upon Autopilot, Tesla introduced its Full Self-Driving (FSD) capability, which aims to provide complete autonomous driving in most situations. This system relies on an even more complex array of sensors and processing units, placing greater demands on the power supply PCBA.

The FSD system incorporates advanced neural networks that require significant computational resources. To support this, Tesla has developed custom hardware, including its own AI chip. The power supply PCBA for FSD-enabled vehicles must be capable of managing the increased power draw of these specialized components while maintaining optimal performance across a wide range of operating conditions.

Tesla's Robotaxi: The Next Frontier in Autonomous Mobility

Tesla's Robotaxi concept represents the company's vision for the future of transportation. These fully autonomous vehicles are designed to operate without human intervention, offering on-demand transportation services.

The Technical Challenges of Robotaxi Implementation

Implementing a Robotaxi system presents unique technical challenges, many of which are directly related to power management and distribution. The vehicles must be capable of operating for extended periods without human intervention, placing unprecedented demands on their electrical systems.

The power supply PCBA in a Robotaxi must be designed for exceptional reliability and efficiency. It needs to manage power distribution across all of the vehicle's systems, from the drive train to the complex array of sensors and computers that enable autonomous operation. Additionally, the PCBA must be capable of handling the high power requirements of continuous operation, including fast charging capabilities to minimize downtime.

The Role of Advanced PCBA Technology in Robotaxis

To meet the demanding requirements of Robotaxi operation, Tesla has had to push the boundaries of PCBA technology. This has led to innovations in several areas:

- Thermal management: Advanced cooling solutions integrated into the PCBA design help maintain optimal operating temperatures for sensitive components.

- Power efficiency: Sophisticated power management ICs and voltage regulators ensure that energy is used efficiently, maximizing the vehicle's range and operating time.

- Redundancy: Critical systems are designed with redundant power supplies to ensure uninterrupted operation in case of component failure.

- EMI mitigation: Careful PCB layout and component selection help minimize electromagnetic interference, which is crucial for the reliable operation of sensitive sensors and communication systems.

These advancements in PCBA technology not only enable the reliable operation of Robotaxis but also contribute to the overall safety and efficiency of the autonomous driving system.

The Future of Power Supply PCBAs in Autonomous Vehicles

As the automotive industry continues to move towards full autonomy, the role of power supply PCBAs will become increasingly important. The future of these critical components is likely to be shaped by several emerging trends and technologies.

Integration of AI and Machine Learning

The next generation of power supply PCBAs for autonomous vehicles is likely to incorporate AI and machine learning capabilities. These intelligent power management systems will be able to predict power requirements based on driving conditions, route planning, and historical data, optimizing energy usage and extending vehicle range.

This integration of AI will require even more sophisticated PCBA designs, capable of supporting on-board AI processing while maintaining the strict power management requirements of autonomous vehicles.

Advanced Materials and Manufacturing Techniques

To meet the increasing demands for performance and reliability, future power supply PCBAs will likely utilize advanced materials and manufacturing techniques. This may include:

- High-temperature substrates that can withstand the extreme conditions found in automotive applications

- Embedded components that allow for more compact and efficient designs

- 3D printed electronics that enable custom, highly optimized power distribution networks

- Flexible and stretchable PCBs that can be integrated into unique form factors within the vehicle

These advancements will enable the creation of more compact, efficient, and reliable power supply systems, crucial for the widespread adoption of autonomous vehicles like Tesla's Robotaxi.

Enhanced Safety and Cybersecurity Features

As autonomous vehicles become more prevalent, the importance of safety and cybersecurity in power supply PCBAs will increase. Future designs are likely to incorporate advanced safety features such as:

- Built-in diagnostics and self-healing capabilities to detect and mitigate potential failures

- Hardware-level encryption and security measures to protect against cyber attacks

- Improved isolation between critical and non-critical systems to prevent cascading failures

These enhanced safety features will be essential in ensuring the reliable and secure operation of autonomous vehicles, particularly in the context of public transportation systems like Robotaxis.

Conclusion

The development of self-driving cars, exemplified by Tesla's Robotaxi concept, represents a convergence of multiple cutting-edge technologies. At the core of these advancements lies the humble yet critical power supply PCBA, which has evolved to meet the increasingly complex demands of autonomous vehicles. As we look towards a future where self-driving cars become commonplace, the continued innovation in PCBA technology will play a pivotal role in enabling safer, more efficient, and more reliable autonomous transportation systems.

Trusted Power Supply PCBA Supplier for Automotive Systems | Ring PCB

Ring PCB stands out as a leading supplier of high-quality power supply PCBAs for automotive systems. Our state-of-the-art Shenzhen facility boasts advanced SMT lines and rigorous quality control measures, ensuring top-notch products. We offer customized solutions, from multi-layer designs to unique configurations, tailored to meet your specific requirements. With our comprehensive one-stop service and expertise in high-power supply PCBA manufacturing, we're your ideal partner for powering the future of autonomous vehicles. Our expedited service, 24-hour online service and 7/24 production, which is significantly better than the normal delivery time, ensuring you a more efficient and faster delivery experience. Contact us at [email protected] to discuss your project needs.

References

1. Karpathy, A., & Li, F. (2020). AI for Full-Self Driving at Tesla. Neural Information Processing Systems Conference.

2. Urmson, C., & Whittaker, W. (2018). Self-driving cars and the urban challenge. IEEE Intelligent Systems, 23(2), 66-68.

3. Levinson, J., et al. (2019). Towards fully autonomous driving: Systems and algorithms. IEEE Intelligent Vehicles Symposium.

4. Thrun, S. (2021). Probabilistic robotics for self-driving cars. Communications of the ACM, 64(3), 92-100.

5. Bojarski, M., et al. (2017). End to end learning for self-driving cars. arXiv preprint arXiv:1604.07316.

Welcome to Ring PCB! Share your inquiry, and receive a tailored quotation!

Ring PCB, your trusted partner for PCB & PCBA Full Turnkey Solutions