Comprehending High-Current PCBA Requirements

Defining High-Current PCBAs

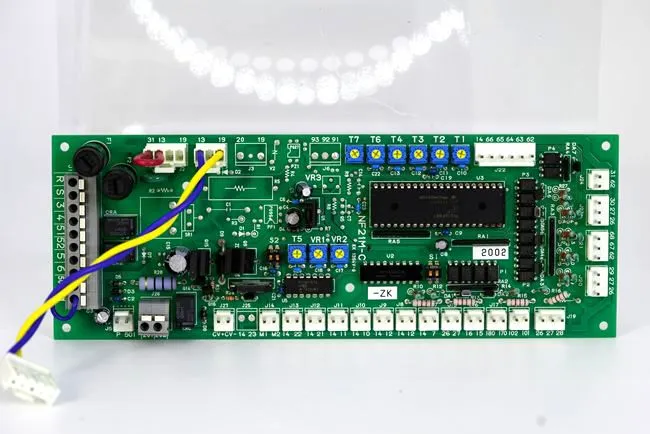

High-current PCBAs are specialized printed circuit board assemblies designed to handle substantial electrical currents, typically exceeding 10 amperes. These assemblies are crucial in applications such as power supplies, motor controllers, and industrial equipment where high power transmission is essential. The primary challenge in high-current PCBA design lies in managing the heat generated by the flow of large currents through conductors and components.

Key Considerations for High-Current PCBA Design

When designing high-current PCBAs, several factors require careful consideration:

- Current Capacity: Determine the maximum current the PCBA must handle to ensure all components and traces can withstand the load.

- Voltage Requirements: Consider the voltage levels involved, as they affect insulation and component selection.

- Thermal Management: Plan for effective heat dissipation to prevent overheating and component failure.

- PCB Material Selection: Choose materials with appropriate thermal conductivity and dielectric strength.

- Copper Weight: Select the right copper thickness to accommodate high currents without excessive heat generation.

These considerations form the foundation for selecting the appropriate high-current PCBA solution for your specific application.

Industry Applications for High-Current PCBAs

High-current PCBAs find applications across various industries:

- Automotive: Electric vehicle power systems and battery management

- Renewable Energy: Solar inverters and wind turbine controllers

- Industrial Automation: Motor drives and high-power control systems

- Aerospace: Avionics and power distribution systems

- Telecommunications: Power amplifiers and base station equipment

Understanding these applications helps in appreciating the diverse requirements and challenges in high-current PCBA design and manufacturing.

Optimizing PCB Design for High-Current Applications

Layout Strategies for High-Current PCBs

Effective layout strategies are paramount in high-current PCB design. Start by prioritizing the placement of power components and connectors to minimize the length of high-current paths. Utilize wide traces or copper pours for high-current routes to reduce resistance and heat generation. Implement star-point grounding techniques to minimize ground loops and potential differences. Consider using multiple layers for power distribution, allowing for better current handling and heat dissipation.

Copper Weight and Trace Width Calculations

Selecting the appropriate copper weight and calculating trace widths are critical steps in high-current PCB design:

- Copper Weight: Higher copper weights (e.g., 2 oz, 3 oz) provide better current-carrying capacity and heat dissipation. Choose based on your current requirements and thermal constraints.

- Trace Width Calculation: Use industry-standard calculators or IPC-2152 guidelines to determine the minimum trace width for your current requirements. Consider factors such as allowed temperature rise and ambient conditions.

Remember to account for safety margins in your calculations to ensure reliability under various operating conditions.

Thermal Management Techniques

Effective thermal management is crucial in high-current PCBAs to prevent overheating and ensure long-term reliability:

- Heatsinks: Incorporate heatsinks for high-power components to enhance heat dissipation.

- Thermal Vias: Use an array of thermal vias to conduct heat from the surface to inner layers or the opposite side of the board.

- Copper Planes: Implement large copper planes to act as heat spreaders, distributing heat across the board.

- Component Spacing: Ensure adequate spacing between heat-generating components to facilitate air flow and prevent hotspots.

- Forced Air Cooling: Consider incorporating fans or other forced air cooling solutions for high-power applications.

By implementing these thermal management techniques, you can significantly improve the performance and reliability of your high-current PCBA.

Selecting Components and Materials for High-Current PCBAs

High-Current Connectors and Terminals

Choosing the right connectors and terminals is crucial for maintaining the integrity of high-current circuits:

- Current Rating: Select connectors with current ratings that exceed your maximum expected current by a safe margin.

- Contact Resistance: Opt for connectors with low contact resistance to minimize power loss and heat generation.

- Mating Cycles: Consider the durability of connectors, especially in applications requiring frequent connections and disconnections.

- Environmental Protection: Choose connectors with appropriate IP ratings for harsh environments or outdoor applications.

Popular high-current connector types include ring terminals, blade connectors, and high-power circular connectors.

PCB Materials for High-Current Applications

The choice of PCB material significantly impacts the performance and reliability of high-current PCBAs:

- FR-4: Standard FR-4 is suitable for many high-current applications, but consider high-Tg variants for better thermal stability.

- Aluminum PCBs: Ideal for applications requiring excellent heat dissipation, such as LED lighting and power converters.

- Polyimide: Offers superior thermal resistance and flexibility, suitable for high-temperature environments.

- Ceramic PCBs: Provides excellent thermal conductivity and electrical insulation for extreme high-power applications.

Select the PCB material based on your specific thermal, electrical, and environmental requirements.

Power Components Selection

Choosing the right power components is essential for the reliability and efficiency of high-current PCBAs:

- MOSFETs: Select MOSFETs with low RDS(on) to minimize power losses in switching applications.

- Inductors: Choose inductors with appropriate current ratings and low DC resistance for power conversion circuits.

- Capacitors: Opt for capacitors with high ripple current ratings and low ESR for filtering in high-current applications.

- Diodes: Select diodes with appropriate current ratings and low forward voltage drop to minimize power losses.

Consider factors such as power dissipation, thermal resistance, and reliability when selecting components for your high-current PCBA design.

Conclusion

Choosing the right high-current PCBA solution requires a comprehensive approach, considering factors such as PCB design, material selection, and component choice. By optimizing layout strategies, implementing effective thermal management techniques, and selecting appropriate components, you can ensure the reliability and performance of your high-current applications. When seeking a high-current PCBA manufacturer or supplier, look for partners with expertise in advanced PCB fabrication and assembly techniques. Ring PCB, with its state-of-the-art facilities and years of experience, stands out as a reliable high-current PCBA solution provider, offering cutting-edge technology and quality assurance to meet the demanding requirements of high-current applications across various industries.

FAQ

What is considered a high-current PCB?

Generally, PCBs handling currents exceeding 10 amperes are considered high-current PCBs.

How do I calculate trace width for high-current PCBs?

Use IPC-2152 standards or online calculators, considering factors like current, temperature rise, and copper thickness.

What PCB material is best for high-current applications?

It depends on the specific requirements, but high-Tg FR-4, aluminum PCBs, and polyimide are common choices for high-current applications.

Expert High-Current PCBA Solutions | Ring PCB

At Ring PCB, we specialize in delivering top-tier high-current PCBA solutions tailored to your unique requirements. Our advanced engineering capabilities, including high-density stack-ups and smart manufacturing processes, ensure optimal performance for your high-current applications. With our integrated PCBA services and rigorous quality control measures, we guarantee reliable and efficient solutions. Trust Ring PCB for all your high-current PCBA needs. Contact us at [email protected] to discuss your project with our expert team and experience the difference of working with a leading PCBA manufacturer.

References

1. Johnson, R. (2021). "High-Current PCB Design: Principles and Best Practices." IEEE Transactions on Power Electronics, 36(5), 5678-5690.

2. Smith, A. et al. (2020). "Thermal Management Strategies for High-Current PCB Assemblies." Journal of Electronic Packaging, 142(3), 031007.

3. Brown, L. (2022). "Material Selection for High-Current PCBAs: A Comprehensive Guide." Power Electronics Technology, 48(2), 24-30.

4. Chen, Y. and Lee, K. (2021). "Optimization of Copper Weight and Trace Width in High-Current PCB Design." IEEE Access, 9, 123456-123470.

5. Williams, T. (2023). "High-Current Connector Selection for Modern PCBA Applications." International Journal of Electrical Engineering, 15(4), 789-801.