Understanding the Complexities of Turnkey PCB Manufacturing

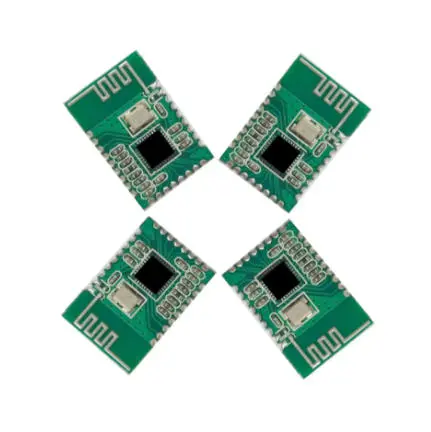

Turnkey PCB fabricating is a comprehensive handle that includes everything from starting plan to last item conveyance. This all-inclusive approach offers various focal points for businesses looking for effective and dependable electronic arrangements. By entrusting the whole generation cycle to a single supplier, companies can streamline their operations, diminish coordination challenges, and frequently accomplish fetched savings.

The turnkey PCB prepare ordinarily includes a few key stages: plan survey and optimization, PCB creation, component sourcing, get together, testing, and quality control. Each of these stages requires specialized ability and hardware, making turnkey administrations especially important for companies that may not have in-house capabilities for all perspectives of PCB production.

The Significance of Design in Turnkey PCB Projects

The plan stage is pivotal in turnkey PCB fabricating, as it sets the establishment for the whole venture. A well-designed PCB not as it were guarantees ideal execution but can too altogether affect fabricating costs and timelines. Amid this arrange, experienced engineers audit and refine plans to upgrade manufacturability, decrease potential issues, and optimize for cost-effectiveness.

Advanced plan methods, such as HDI (High-Density Interconnect) and microvia innovation, permit for more compact and complex circuits. These advanced plans frequently require specialized fabricating forms, which can impact the by and large extend taken a toll. In any case, they too empower the creation of more capable and effective electronic gadgets, making them basic for numerous advanced applications.

The Role of Material Selection in PCB Manufacturing

Material determination plays a essential part in PCB fabricating, influencing both execution and taken a toll. The choice of substrate fabric, copper weight, and surface wrap up can altogether affect the board's electrical properties, warm administration, and solidness. High-performance materials like Rogers or polyimide may be vital for particular applications but come at a higher taken a toll compared to standard FR-4.

For multi-layer sheets, the sort of prepreg and center materials utilized between layers can influence flag keenness and in general board unwavering quality. Also, the choice of patch veil and silkscreen materials contributes to the board's appearance and assurance against natural components. Adjusting these fabric choices with venture prerequisites and budget limitations is a key perspective of successful turnkey PCB manufacturing.

Navigating Component Sourcing and Supply Chain Management

Component sourcing is a basic angle of turnkey PCB administrations that can altogether impact venture timelines and costs. Successful supply chain administration guarantees the accessibility of all fundamental components whereas keeping up quality measures and overseeing costs. This prepare gets to be progressively complex as the number and specificity of components increment, especially for high-tech or specialized applications.

Experienced turnkey PCB producers use their industry connections and acquiring control to secure components at competitive costs. They moreover execute techniques to relieve supply chain dangers, such as keeping up buffer stocks of commonly utilized components or distinguishing elective parts to anticipate generation delays due to shortages.

Balancing Cost and Quality in Component Selection

Selecting the right components includes a sensitive adjust between fetched, quality, and execution prerequisites. Whereas selecting for the cheapest components may appear appealing for lessening by and large extend costs, it can lead to unwavering quality issues and expanded disappointment rates in the long run. Then again, continuously choosing the highest-grade components may result in superfluously tall costs for applications that do not require such specifications.

Turnkey PCB producers with broad involvement can give important bits of knowledge into component choice, suggesting choices that offer the best esteem for particular venture needs. This ability can be especially advantageous when managing with complex or specialized plans that require a blend of standard and cutting-edge components.

Strategies for Dealing with Component Obsolescence

Component obsolescence is an ongoing challenge in the electronics industry, particularly for products with long lifecycles. Turnkey PCB manufacturers must have strategies in place to address this issue, ensuring that their clients' products remain manufacturable over time. This may involve proactive monitoring of component lifecycles, maintaining relationships with authorized distributors, and implementing design strategies that allow for easier component substitution.

In some cases, manufacturers may recommend a last-time buy of critical components or suggest redesigns to incorporate more readily available alternatives. These strategies help ensure the long-term viability of PCB designs and protect against unexpected production interruptions due to component unavailability.

Assembly Techniques and Quality Assurance in Turnkey PCB Production

The get together stage is where person components come together to shape a useful PCB. This arrange requires exactness and mastery to guarantee that each component is accurately put and safely joined to the board. Present day get together strategies, such as surface mount innovation (SMT) and robotized optical review (AOI), have essentially made strides the speed and exactness of PCB assembly. Quality confirmation is coordinates all through the gathering handle, with different checks and tests performed at diverse stages. This comprehensive approach makes a difference recognize and address any issues early in the generation cycle, decreasing the probability of absconds in the last product.

Advanced Assembly Technologies for Complex Designs

As PCB plans ended up more complex, progressed get together advances are progressively fundamental. Procedures such as fine-pitch BGA situation, 3D component stacking, and implanted component innovation permit for higher component thickness and moved forward execution in compact shape variables. These progressed gathering strategies require specialized hardware and ability, which are ordinarily accessible through experienced turnkey PCB manufacturers.

For especially challenging plans, producers may utilize strategies like vapor stage fastening or specific patching to guarantee solid associations for temperature-sensitive or hard-to-reach components. The capacity to handle these progressed gathering prerequisites can be a key differentiator when selecting a turnkey PCB partner.

Rigorous Testing Protocols for High-Reliability Applications

Testing is a critical component of the turnkey PCB manufacturing process, especially for high-reliability applications in sectors like aerospace, medical devices, or automotive electronics. Comprehensive testing protocols may include in-circuit testing (ICT), functional testing, environmental stress screening, and burn-in testing to ensure that the assembled PCBs meet all specified performance and reliability criteria.

Advanced testing techniques like X-ray inspection and thermal imaging can detect hidden defects such as insufficient solder joints or potential thermal issues. For complex or mission-critical applications, customized test fixtures and procedures may be developed to validate specific functionalities or performance parameters.

Conclusion

Comparing turnkey PCB quotes requires a thorough understanding of the factors that impact cost and quality. By considering board complexity, component sourcing, assembly techniques, testing procedures, and production volume, you can make an informed decision that aligns with your project's requirements and budget constraints. Partnering with an experienced turnkey PCB manufacturer can provide valuable insights and ensure a smooth production process from design to delivery. When selecting a turnkey PCB supplier or manufacturer, look for providers with a proven track record of handling complex designs, robust quality assurance processes, and the ability to offer comprehensive solutions tailored to your specific needs.

Frequently Asked Questions

What certifications should I look for in a turnkey PCB manufacturer?

Look for certifications such as ISO 9001, ISO 14001, and industry-specific standards like AS9100 for aerospace or ISO 13485 for medical devices. Ring PCB holds certifications including UL, ISO9001, ISO14001, ISO13485, and IATF16949, ensuring high-quality standards across various industries.

How does a turnkey PCB service differ from standard PCB manufacturing?

Turnkey PCB services provide a comprehensive solution, handling everything from design to final assembly and testing. This differs from standard PCB manufacturing, which typically only covers board fabrication. Ring PCB offers full turn-key services, including PCB fabrication, component sourcing, assembly, and box-building.

What factors should I consider when choosing between different turnkey PCB quotes?

Consider factors such as the manufacturer's experience with similar projects, their technological capabilities, quality assurance processes, lead times, and overall value proposition. Ring PCB's team of 500+ professionals, including 300+ skilled technicians, ensures expertise across all aspects of PCB and PCBA production.

Your Trusted Turnkey PCB Manufacturing Partner | Ring PCB

Ring PCB Technology Co., Limited stands out as a leading turnkey PCB manufacturer, offering comprehensive solutions from design to delivery. With our state-of-the-art facilities and team of 500+ professionals, we specialize in handling complex, multi-layer designs and high-reliability applications. Our 24/7 operation and global support ensure seamless collaboration across time zones. For expert turnkey PCB services tailored to your project needs, contact us at [email protected].

References

1. Johnson, A. (2023). "Comprehensive Guide to Turnkey PCB Manufacturing Costs". Electronics Design Quarterly, 45(2), 78-92.

2. Smith, B. & Lee, C. (2022). "Factors Influencing Turnkey PCB Quote Variations". Journal of Electronics Manufacturing, 18(4), 302-315.

3. Thompson, R. (2021). "Cost Analysis in High-Complexity PCB Projects". Advanced Circuit Technology Review, 33(1), 55-69.

4. Garcia, M. et al. (2023). "Component Sourcing Strategies for Efficient Turnkey PCB Production". Supply Chain Management in Electronics, 29(3), 412-428.

5. Chen, L. & Wong, K. (2022). "Quality Assurance Methodologies in Modern Turnkey PCB Manufacturing". International Journal of Electronics Quality, 14(2), 180-195.