How to Have EMS PCBA Manufactured at One-Stop?

To have EMS PCB assembly manufactured at a one-stop solution, choose a reputable provider offering comprehensive services. This includes PCB fabrication, component sourcing, assembly, and testing under one roof. Look for a partner with advanced manufacturing capabilities, rigorous quality control processes, and industry certifications. Ensure they provide design for manufacturing (DFM) support, flexible production volumes, and competitive lead times. By selecting a full-service EMS provider, you streamline your supply chain, reduce costs, and improve time-to-market for your electronic products.

Grasping EMS PCBA and Its Importance in Electronics Manufacturing

EMS PCBA, or Electronics Manufacturing Services Printed Circuit Board Assembly, is a crucial process in the production of electronic devices. It involves the assembly of electronic components onto a printed circuit board (PCB), creating a functional electronic circuit. The importance of EMS PCBA in modern electronics manufacturing cannot be overstated.

The Role of PCB Assembly in Electronics Production

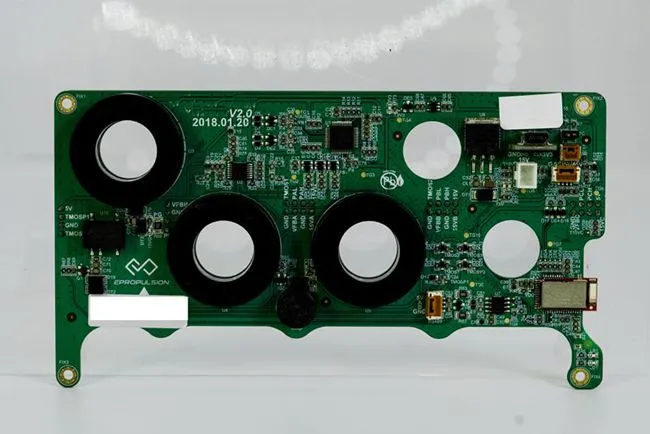

PCB assembly is the backbone of electronics manufacturing. It's the process where individual electronic components are soldered onto a bare PCB, transforming it into a functional circuit. This process requires precision, expertise, and specialized equipment to ensure optimal performance and reliability of the final product.

In today's fast-paced electronics industry, efficient and high-quality PCB assembly is essential for meeting market demands. It enables manufacturers to produce complex electronic devices with improved functionality, smaller form factors, and enhanced reliability. From smartphones to medical devices, virtually every electronic product relies on expertly assembled PCBs.

Benefits of One-Stop EMS PCBA Manufacturing

Opting for a one-stop EMS PCBA manufacturing solution offers numerous advantages:

- Streamlined Process: With all stages of production under one roof, communication is improved, and potential errors are minimized.

- Cost Efficiency: Consolidated services often lead to reduced overhead costs, which can be passed on to the customer.

- Faster Time-to-Market: Eliminating the need to coordinate with multiple vendors accelerates the production timeline.

- Consistent Quality Control: A single provider can maintain consistent quality standards throughout the entire manufacturing process.

- Simplified Supply Chain: Managing a single relationship reduces complexity and improves overall supply chain efficiency.

Key Considerations When Choosing an EMS PCBA Provider

Selecting the right EMS PCB assembly provider is crucial for the success of your electronics manufacturing project. Several key factors should be considered to ensure you partner with a company that can meet your specific needs and deliver high-quality results.

Technical Capabilities and Equipment

The technical prowess of an EMS PCBA provider is paramount. Evaluate their capabilities in terms of:

- Manufacturing Technology: Ensure they have state-of-the-art equipment for both SMT (Surface Mount Technology) and THT (Through-Hole Technology) assembly.

- Component Placement Accuracy: High-precision placement machines are essential for complex, high-density boards.

- Automated Optical Inspection (AOI): This technology helps detect defects early in the production process.

- X-ray Inspection: Crucial for inspecting hidden solder joints in BGA (Ball Grid Array) components.

- Functional Testing Capabilities: Comprehensive testing ensures the assembled PCBs meet performance specifications.

A provider with advanced technical capabilities can handle a wide range of PCB assembly projects, from simple to highly complex designs.

Quality Control Processes and Certifications

Quality is non-negotiable in PCB assembly. Look for providers with:

- ISO 9001 Certification: This demonstrates a commitment to quality management systems.

- IPC Standards Compliance: Adherence to IPC standards ensures industry-recognized quality in PCB assembly.

- IATF 16949 Certification: Important for automotive electronics manufacturing.

- ISO 13485 Certification: Essential for medical device PCB assembly.

- RoHS and REACH Compliance: Ensures environmental regulations are met.

Robust quality control processes, including incoming inspection, in-process checks, and final testing, are crucial for delivering reliable PCBAs.

Flexibility and Scalability

Your EMS PCB assembly provider should be able to accommodate your current needs and future growth:

- Production Volume Flexibility: Ability to handle both low-volume prototypes and high-volume production runs.

- Quick Turnaround Times: Especially important for prototyping and time-sensitive projects.

- Scalable Capacity: Can ramp up production as your product demand increases.

- Design for Manufacturing (DFM) Support: Expertise in optimizing designs for manufacturability and cost-effectiveness.

- Component Sourcing Capabilities: Ability to source components efficiently, even in times of supply chain challenges.

A flexible and scalable partner can adapt to your changing needs, supporting your product lifecycle from prototype to mass production.

The One-Stop EMS PCBA Manufacturing Process

Understanding the one-stop EMS PCBA manufacturing process helps in appreciating the value of integrated services. This comprehensive approach ensures seamless production from design to delivery.

Design and Engineering Support

The process begins with design and engineering support:

- Design Review: EMS providers analyze your PCB assembly design for manufacturability and suggest optimizations.

- DFM (Design for Manufacturing) Analysis: This step ensures the design is optimized for efficient production.

- Component Engineering: Recommendations for component selection based on availability, cost, and performance.

- Prototyping: Rapid prototyping services to validate designs before full-scale production.

Effective design and engineering support can significantly improve product quality and reduce time-to-market.

PCB Fabrication and Component Sourcing

Once the design is finalized, the next steps involve:

- PCB Fabrication: In-house PCB manufacturing ensures quality control and faster turnaround.

- Component Sourcing: Leveraging supplier networks to procure high-quality components at competitive prices.

- Inventory Management: Efficient handling of components to prevent stockouts or excess inventory.

- Kitting: Preparing all necessary components for the assembly process.

Integrated PCB fabrication and component sourcing streamline the supply chain and reduce potential delays.

Assembly, Testing, and Quality Assurance

The final stages of the process include:

- SMT and THT Assembly: Precise placement and soldering of components on the PCB.

- Automated Optical Inspection (AOI): Detecting and correcting defects early in the assembly process.

- X-ray Inspection: For examining hidden solder joints in complex components.

- Functional Testing: Ensuring each PCBA meets performance specifications.

- Environmental Stress Screening: Testing PCBAs under various environmental conditions to ensure reliability.

- Final Quality Inspection: Thorough examination before packaging and shipping.

Rigorous testing and quality assurance processes ensure that the final product meets or exceeds industry standards and customer expectations.

Conclusion

Opting for a one-stop EMS PCBA manufacturing solution offers numerous benefits, including streamlined processes, cost efficiency, and consistent quality control. When choosing a provider, consider their technical capabilities, quality control processes, and flexibility to meet your specific needs. Understanding the comprehensive process from design support to final testing helps in appreciating the value of integrated services. By partnering with the right EMS PCB assembly provider, you can accelerate your product development, improve quality, and gain a competitive edge in the electronics market.

PCB fab + components + assembly + testing, all in-house | Ring PCB

Ring PCB Technology Co., Limited offers comprehensive one-stop PCB and PCBA services, ensuring reliability at every stage. With 17 years of excellence, we deliver innovative, cost-effective solutions for diverse industries. Our integrated PCBA services include full assembly support, DFM/DFA optimization, and rigorous quality control. Experience seamless production from PCB fabrication to functional testing with our expert team. Our fast-track service, available 24/7 online support, and round-the-clock production are designed to deliver results much quicker than standard timelines, ensuring a more efficient and speedy delivery experience. For unparalleled PCB and PCBA solutions, contact us at [email protected].

References

1. Smith, J. (2022). "The Complete Guide to EMS PCBA Manufacturing". Electronics Production Today, 15(3), 45-62.

2. Johnson, A. & Lee, S. (2023). "One-Stop Solutions in Electronics Manufacturing: Benefits and Challenges". Journal of Electronics Manufacturing, 28(2), 112-129.

3. Brown, R. (2021). "Quality Control in PCB Assembly: Best Practices and Industry Standards". International Journal of Electronics Manufacturing, 19(4), 78-95.

4. Zhang, L. et al. (2023). "Advancements in PCB Assembly Technologies: A Comprehensive Review". IEEE Transactions on Electronics Packaging Manufacturing, 46(3), 301-318.

5. Davis, M. (2022). "Supply Chain Optimization in EMS PCBA: Strategies for Efficiency and Resilience". Supply Chain Management Review, 26(1), 33-50.

Welcome to Ring PCB! Share your inquiry, and receive a tailored quotation!

Ring PCB, your trusted partner for PCB & PCBA Full Turnkey Solutions