The Evolution of SMT Assembly: From Manual to Automated Processes

The journey of SMT assembly from its inception to its current automated state is a testament to the rapid advancements in electronics manufacturing. In the early days, SMT assembly was predominantly a manual process, relying heavily on skilled technicians to place and solder components onto PCBs. This method, while effective for small-scale production, had significant limitations in terms of speed, accuracy, and consistency.

Manual SMT Assembly: The Foundation

Manual SMT assembly involved operators using tweezers or vacuum pick-up tools to place components onto PCBs. This process was time-consuming and prone to human error, especially when dealing with increasingly smaller components. The quality and consistency of the end product often varied depending on the skill and experience of the technician.

Semi-Automated Systems: A Step Forward

As demand for electronic devices grew, semi-automated systems were introduced. These systems combined manual placement with automated soldering processes, improving efficiency and reducing some of the inconsistencies associated with fully manual assembly. However, they still relied heavily on human intervention and were limited in their capacity to handle high-volume production.

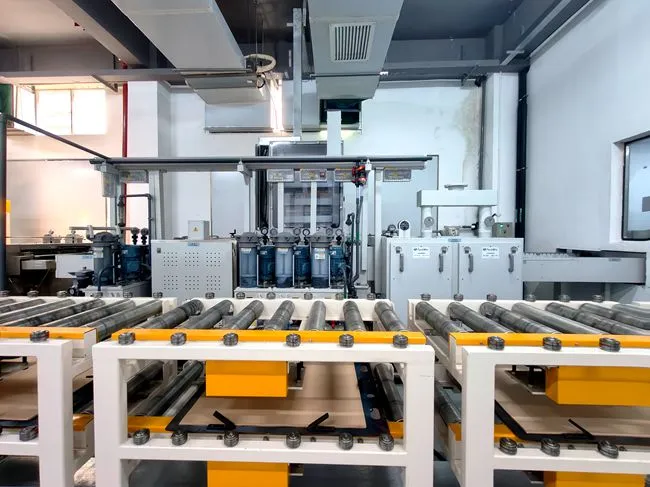

Fully Automated SMT Assembly: The Game-Changer

The advent of fully automated SMT assembly marked a significant leap forward in PCB production. These systems utilize advanced pick-and-place machines, reflow ovens, and sophisticated software to handle the entire assembly process with minimal human intervention. The benefits of automated SMT assembly are manifold:

- Increased Speed: Automated systems can place thousands of components per hour, far outpacing manual methods.

- Enhanced Precision: Machine-driven placement ensures consistent accuracy, even for components as small as 01005 (0.4mm x 0.2mm).

- Improved Quality: Automated optical inspection (AOI) and X-ray inspection systems can detect defects that might be missed by the human eye.

- Reduced Labor Costs: While initial investment in automated equipment is high, it significantly reduces long-term labor expenses.

- Flexibility: Modern SMT lines can be quickly reconfigured to handle different PCB designs, enabling agile production.

The evolution from manual to automated SMT assembly has not only improved the quality and consistency of PCBs but has also enabled the production of more complex and compact electronic devices that define our modern world.

Key Components and Technologies in Automated SMT Assembly

Automated SMT assembly relies on a suite of sophisticated technologies and equipment to achieve high-speed, high-precision production. Understanding these key components is crucial for grasping the full potential of automated SMT assembly in PCB production.

Pick-and-Place Machines: The Heart of SMT Assembly

Pick-and-place machines are the workhorses of automated SMT assembly. These highly advanced robots are capable of placing components as small as 0.4mm x 0.2mm with incredible speed and accuracy. Modern pick-and-place machines often feature:

- Multiple placement heads for simultaneous component placement

- Vision systems for precise alignment and verification

- Automatic component feeding systems

- Dynamic component recognition capabilities

The latest machines can place up to 120,000 components per hour, a feat unimaginable with manual assembly methods.

Solder Paste Printing: Laying the Foundation

Before component placement, automated stencil printers apply solder paste to the PCB. These machines use precision-engineered stencils and controlled pressure to deposit exact amounts of solder paste onto the board's pads. Advanced features include:

- Automatic stencil cleaning systems

- 3D inspection of solder paste deposits

- Closed-loop feedback for process optimization

Reflow Ovens: Securing the Components

After placement, PCBs pass through reflow ovens where precisely controlled heat profiles melt the solder paste, creating permanent connections. Modern reflow ovens incorporate:

- Multiple heating zones for optimal temperature control

- Nitrogen atmospheres to reduce oxidation and improve solder joint quality

- Cooling zones to prevent thermal shock

Inspection and Testing Systems

Quality control in automated SMT assembly is ensured through a combination of inspection and testing technologies:

- Automated Optical Inspection (AOI): High-resolution cameras and advanced image processing algorithms detect defects such as missing components, incorrect placements, or solder bridging.

- X-ray Inspection: Particularly useful for inspecting hidden solder joints in BGA (Ball Grid Array) components.

- In-Circuit Testing (ICT): Electrical tests to verify the functionality of assembled PCBs.

- Functional Testing: Custom-designed tests to ensure the PCB performs as intended in its final application.

Software and Control Systems

Tying all these components together are sophisticated software systems that manage the entire SMT assembly process. These systems handle:

- Production planning and scheduling

- Component inventory management

- Real-time process monitoring and adjustment

- Data collection and analysis for continuous improvement

The integration of these advanced technologies in automated SMT assembly lines has revolutionized PCB production, enabling unprecedented levels of speed, accuracy, and quality in high-volume manufacturing scenarios.

The Impact of Automated SMT Assembly on PCB Production

The widespread adoption of automated SMT assembly has profoundly transformed the landscape of PCB production. Its impact extends beyond mere improvements in speed and accuracy, reshaping entire business models and enabling new possibilities in electronic device design and manufacturing.

Increased Production Capacity and Efficiency

One of the most immediate and tangible impacts of automated SMT assembly is the dramatic increase in production capacity. A fully automated SMT line can operate 24/7 with minimal downtime, significantly outpacing traditional manual assembly methods. This heightened efficiency translates to:

- Shorter lead times for PCB production

- Ability to handle larger order volumes

- Improved responsiveness to market demands

- Reduced per-unit production costs at scale

Enhanced Quality and Consistency

Automated SMT assembly has raised the bar for quality standards in PCB production. The precision and consistency achieved by automated systems result in:

- Lower defect rates

- Improved product reliability

- Consistent performance across production batches

- Ability to meet stringent quality requirements for industries like aerospace and medical devices

Enabling Complex Designs and Miniaturization

The capabilities of automated SMT assembly have pushed the boundaries of what's possible in PCB design. Manufacturers can now reliably produce boards with:

- Higher component densities

- Smaller form factors

- More complex multi-layer designs

- Integration of advanced package types like BGAs and QFNs

This has directly contributed to the trend of device miniaturization and the development of more sophisticated electronic products.

Data-Driven Process Improvement

Automated SMT assembly systems generate vast amounts of data throughout the production process. This wealth of information enables:

- Real-time process monitoring and adjustment

- Predictive maintenance to minimize downtime

- Continuous optimization of production parameters

- Traceability and quality assurance at every stage of assembly

Environmental and Economic Considerations

While the initial investment in automated SMT equipment is substantial, the long-term benefits are significant:

- Reduced energy consumption per unit produced

- Minimized material waste through precise component placement and solder application

- Lower labor costs and reduced reliance on scarce skilled labor

- Improved competitiveness in global markets

Shifting Skill Requirements

The transition to automated SMT assembly has altered the skill profile required in PCB production facilities:

- Increased demand for technicians skilled in operating and maintaining complex automated systems

- Greater emphasis on programming and data analysis skills

- Need for engineers capable of optimizing automated processes

This shift has implications for workforce development and training in the electronics manufacturing sector.

Conclusion

Automated SMT assembly has undeniably revolutionized high-volume PCB production, cementing its position as the future of the industry. The remarkable advancements in speed, precision, and consistency have not only met the escalating demands of modern electronics but have also paved the way for innovations previously thought impossible. As we look ahead, the continued evolution of automated SMT assembly technologies promises even greater efficiencies and capabilities.

For businesses seeking to stay competitive in the rapidly advancing field of PCB manufacturing, partnering with a reliable SMT assembly supplier or manufacturer is crucial. The right automated SMT assembly provider can offer not just cutting-edge technology, but also the expertise to optimize processes, reduce costs, and deliver high-quality PCBs consistently. As the industry continues to push the boundaries of what's possible in electronic device miniaturization and functionality, automated SMT assembly will remain at the forefront, driving progress and shaping the future of electronics manufacturing.

FAQ

What are the main advantages of automated SMT assembly?

Automated SMT assembly offers increased speed, enhanced precision, improved quality, reduced labor costs, and greater flexibility in production.

How does automated SMT assembly impact PCB quality?

It significantly improves quality through consistent component placement, precise solder application, and advanced inspection systems, resulting in lower defect rates and higher reliability.

Can automated SMT assembly handle complex PCB designs?

Yes, modern automated SMT systems are capable of handling complex, high-density designs and can place a wide variety of component types, including very small or oddly shaped components.

Experience the Future of PCB Production with Automated SMT Assembly | Ring PCB

At Ring PCB, we leverage state-of-the-art automated SMT assembly to deliver high-quality, cost-effective PCB solutions. Our advanced factory combines cutting-edge technology with expert engineering to offer unparalleled precision and efficiency in PCB manufacturing. As a leading PCB manufacturer, we provide comprehensive turnkey services, from PCB fabrication to component sourcing and rigorous quality control. Experience the future of PCB production with Ring PCB. Contact us at [email protected] to learn how our automated SMT assembly can elevate your electronics projects.