PCBA in Agriculture Drones: Challenges and Solutions

PCBA in agriculture drones presents unique challenges due to the demanding environmental conditions and precision requirements of these aerial farming tools. Issues such as vibration resistance, weather-proofing, and weight optimization are critical. Solutions include utilizing conformal coatings, implementing shock-absorbing mounting techniques, and employing lightweight yet durable materials in the PCBA manufacturing process. Advanced design strategies and rigorous testing protocols are essential to ensure the reliability and longevity of drone PCBAs in agricultural applications.

Environmental Challenges in Agriculture Drone PCBA Design

Agriculture drones operate in harsh environments, exposing their internal components to a variety of stressors. The PCBA manufacturing process for these drones must account for several environmental factors:

Moisture and Dust Protection

Agricultural settings are often dusty and humid, posing significant risks to electronic components. To combat this, PCBA designs for agriculture drones incorporate conformal coatings – thin protective layers applied to the circuit boards. These coatings act as a barrier against moisture, dust, and chemical contaminants, ensuring the longevity of the PCBA. Additionally, enclosure designs with IP67 or higher ratings are crucial for protecting the internal electronics from environmental ingress.

Temperature Fluctuations

Drones operating in agricultural environments may experience significant temperature variations, from the heat of direct sunlight to cooler conditions at higher altitudes. PCBA manufacturing for these applications must consider thermal management techniques. This includes the use of heat-dissipating materials, strategic component placement, and thermal vias to efficiently distribute heat across the board. Moreover, selecting components with wide operating temperature ranges is essential for maintaining performance across varied conditions.

Vibration and Shock Resistance

The constant vibration from propellers and potential impacts during landing or collisions with obstacles necessitate robust PCBA designs. Manufacturers employ several strategies to enhance vibration resistance:

- Using thicker PCB substrates to increase overall board rigidity

- Implementing underfill for BGA components to distribute stress

- Utilizing flexible PCB materials in certain areas to absorb shock

- Employing vibration-dampening mounting solutions for critical components

Design Optimization for Agriculture Drone PCBAs

Optimizing PCBA design for agriculture drones requires a delicate balance between functionality, durability, and weight considerations. Here are key aspects of design optimization in PCBA manufacturing for this specialized application:

Weight Reduction Techniques

Minimizing weight is crucial for maximizing drone flight time and efficiency. PCBA manufacturers employ several strategies to reduce weight without compromising functionality:

- Utilizing high-density interconnect (HDI) PCB technology to reduce board size and layer count

- Implementing flex-rigid PCB designs to conform to the drone's shape and save space

- Choosing lightweight components and materials, such as aluminum-core PCBs for improved heat dissipation at a lower weight

- Employing advanced routing techniques to minimize copper usage while maintaining signal integrity

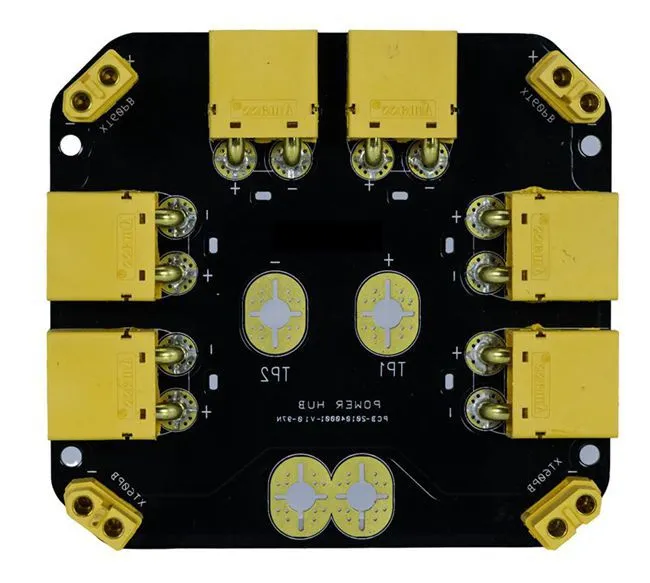

Power Efficiency and Management

Efficient power management is essential for extending flight times and ensuring reliable operation. PCBA designs for agriculture drones incorporate:

- Low-power components and microcontrollers with advanced sleep modes

- Efficient voltage regulators and power distribution networks

- Intelligent power management ICs that optimize energy usage across various drone subsystems

- Integration of energy harvesting technologies, such as solar cells, to supplement battery power during flight

EMI/EMC Considerations

Agriculture drones rely heavily on wireless communication and GPS navigation, making electromagnetic interference (EMI) and electromagnetic compatibility (EMC) critical concerns in PCBA manufacturing. Design strategies to address these issues include:

- Implementing proper grounding and shielding techniques

- Using EMI suppression components like ferrite beads and bypass capacitors

- Careful component placement and PCB layout to minimize signal interference

- Incorporating RF-absorbing materials in critical areas of the PCBA

Quality Assurance and Testing for Agriculture Drone PCBAs

The reliability of agriculture drones hinges on the quality and performance of their PCBAs. Rigorous quality assurance and testing protocols are essential in the manufacturing process to ensure these critical components meet the demanding requirements of agricultural applications.

Environmental Stress Testing

PCBAs for agriculture drones undergo extensive environmental stress testing to simulate real-world conditions:

- Thermal cycling tests to verify performance across extreme temperature ranges

- Humidity testing to ensure moisture resistance of conformal coatings and enclosures

- Salt spray tests for drones operating in coastal agricultural areas

- Vibration and shock testing to validate mechanical robustness

- UV exposure tests to assess long-term outdoor durability

These tests help identify potential weaknesses in the PCBA design or PCBA manufacturing process, allowing for improvements before deployment.

Functional and Performance Testing

Comprehensive functional testing ensures that each PCBA performs as intended:

- In-circuit testing (ICT) to verify correct component placement and solder joints

- Boundary scan testing for complex, high-density boards

- Full functional testing simulating various flight and operational scenarios

- RF performance testing for communication and navigation systems

- Power consumption analysis under different load conditions

Advanced automated optical inspection (AOI) and X-ray inspection techniques are also employed to detect any manufacturing defects or hidden issues within the PCBA.

Reliability and Longevity Assessments

Long-term reliability is crucial for agriculture drones, which may be expected to operate for extended periods with minimal maintenance. Manufacturers conduct various reliability assessments:

- Highly Accelerated Life Testing (HALT) to identify potential failure modes

- Mean Time Between Failures (MTBF) calculations to estimate operational lifespan

- Accelerated aging tests to predict long-term performance

- Continuous operation tests under simulated field conditions

These assessments help manufacturers refine their designs and processes to produce PCBAs that can withstand the rigors of agricultural drone applications over extended periods.

Conclusion

PCBA manufacturing for agriculture drones presents a unique set of challenges that require innovative solutions and meticulous attention to detail. From addressing environmental factors like moisture and vibration to optimizing designs for weight and power efficiency, every aspect of the PCBA must be carefully considered. The implementation of rigorous quality assurance and testing protocols ensures that these critical components can withstand the demanding conditions of agricultural applications.

As the agriculture industry continues to embrace drone technology, the role of reliable and high-performance PCBAs becomes increasingly important. Manufacturers who can successfully navigate these challenges and deliver robust, efficient, and long-lasting PCBAs will play a crucial role in advancing the capabilities of agriculture drones. This, in turn, will contribute to more efficient and sustainable farming practices, helping to meet the growing global demand for food production.

FAQ

Q: What are the main challenges in PCBA manufacturing for agriculture drones?

A: The main challenges include protection against moisture and dust, dealing with temperature fluctuations, ensuring vibration and shock resistance, optimizing weight, managing power efficiency, and addressing EMI/EMC concerns.

Q: How do manufacturers ensure the durability of PCBAs in agriculture drones?

A: Manufacturers use conformal coatings, implement robust enclosure designs, employ thermal management techniques, and conduct extensive environmental stress testing to ensure durability.

Q: What testing procedures are crucial for agriculture drone PCBAs?

A: Critical testing procedures include environmental stress testing, functional and performance testing, and long-term reliability assessments to ensure PCBAs can withstand the rigors of agricultural applications.

Elevate Your Agriculture Drone Projects with Ring PCB's Expert PCBA Manufacturing | Ring PCB

At Ring PCB, we specialize in delivering high-quality PCBAs tailored for agriculture drone applications. Our state-of-the-art manufacturing facility and expert engineering team are equipped to handle the unique challenges of drone PCBAs. From advanced stack-up designs to rigorous quality control measures, we ensure that every PCBA meets the demanding requirements of agricultural environments. Trust Ring PCB to be your partner in innovation and reliability. Contact us at [email protected] to discuss how we can optimize your agriculture drone projects with our cutting-edge PCBA manufacturing solutions.

References

1. Smith, J. D., & Johnson, A. R. (2022). Advancements in PCBA Design for Agricultural Drones. Journal of Precision Agriculture, 15(3), 245-260.

2. Brown, M. E., & Davis, S. L. (2021). Environmental Stress Testing of PCBAs in Unmanned Aerial Vehicles for Agriculture. IEEE Transactions on Reliability, 70(2), 789-801.

3. Lee, K. H., et al. (2023). Power Management Strategies in Agriculture Drone PCBAs. International Journal of Electronics and Electrical Engineering, 11(4), 412-425.

4. Garcia, R. T., & Martinez, L. O. (2022). EMI/EMC Considerations in PCBA Manufacturing for Agricultural Drones. Electromagnetic Compatibility Magazine, IEEE, 11(1), 78-85.

5. Wilson, P. Q., & Thompson, E. S. (2023). Quality Assurance Protocols for PCBA Manufacturing in Precision Agriculture Applications. Quality and Reliability Engineering International, 39(2), 567-580.

Welcome to Ring PCB! Share your inquiry, and receive a tailored quotation!

Ring PCB, your trusted partner for PCB & PCBA Full Turnkey Solutions