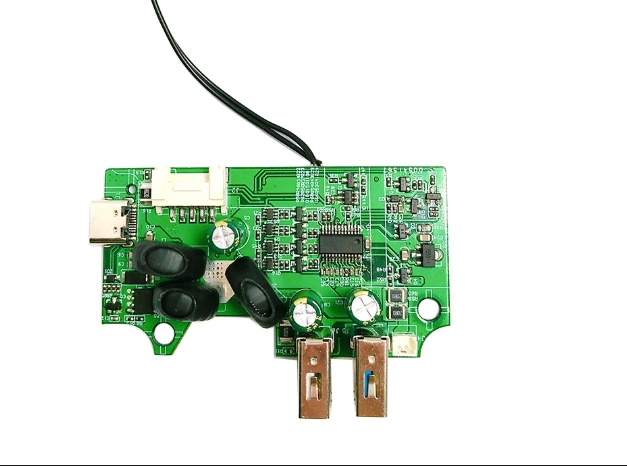

Power Supply PCBA Board Specifications and Features

Power Supply PCBA (Printed Circuit Board Assembly) boards are critical components in electronic devices, responsible for converting and regulating electrical power. These boards encompass a range of specifications and features designed to ensure efficient power management, safety, and reliability. Typical specifications include input voltage range, output voltage and current ratings, efficiency, operating temperature range, and protection features. Key features often involve multi-layer designs for complex circuitry, thermal management solutions, and advanced component integration for compact yet powerful performance.

Understanding Power Supply PCBA Board Specifications

Electrical Specifications

The electrical specifications of power supply PCBA boards are paramount to their functionality and compatibility with various devices. These specifications typically include:

- Input Voltage Range: Power supply PCBAs are designed to accept a specific range of input voltages, often accommodating both AC and DC inputs. Common ranges include 85-264VAC for universal input designs or 18-36VDC for DC-DC converters.

- Output Voltage and Current: These boards provide regulated output voltages, which can be single or multiple depending on the design. Output currents are specified to meet the power demands of the target application.

- Efficiency: Modern power supply PCBAs strive for high efficiency, often exceeding 90% in advanced designs. This minimizes power loss and heat generation.

- Ripple and Noise: Low ripple and noise specifications ensure clean power output, critical for sensitive electronics.

Physical Specifications

The physical attributes of power supply PCBA boards are crucial for integration into end products:

- Board Dimensions: Sizes vary widely based on application, from compact designs for portable devices to larger boards for high-power industrial applications.

- Layer Count: Power supply PCBAs can range from simple 2-layer designs to complex multi-layer boards, often utilizing 4 to 12 layers for optimal performance and EMI suppression.

- Thermal Design: Specifications often include maximum operating temperature and may detail heat dissipation methods such as heatsinks or thermal vias.

Regulatory Compliance

Power supply PCBAs must adhere to various safety and electromagnetic compatibility standards:

- Safety Standards: Compliance with IEC/UL 60950 for IT equipment or IEC/UL 62368-1 for audio/video equipment is common.

- EMC Standards: Boards typically meet EMC requirements such as FCC Part 15 or EN 55032 for emissions and EN 61000 series for immunity.

- Environmental Standards: RoHS compliance ensures the board is free from hazardous substances.

Essential Features of Power Supply PCBA Boards

Protection Mechanisms

Modern power supply PCBA boards incorporate various protection features to ensure safe operation:

- Overcurrent Protection (OCP): Prevents damage from excessive current draw.

- Overvoltage Protection (OVP): Safeguards against voltage spikes that could harm connected devices.

- Short Circuit Protection: Automatically shuts down the power supply in case of a short circuit.

- Thermal Protection: Monitors temperature and reduces output or shuts down to prevent overheating.

Power Management and Control

Advanced power supply PCBAs offer sophisticated management features:

- Power Factor Correction (PFC): Improves efficiency and reduces harmonic distortion in AC-DC converters.

- Programmable Output: Allows dynamic adjustment of output voltage and current limits.

- Remote Sensing: Compensates for voltage drops in power distribution, ensuring accurate voltage at the load.

- Digital Control: Implements microcontroller-based control for enhanced performance and flexibility.

Connectivity and Monitoring

Modern power supply PCBAs often include features for integration and monitoring:

- Communication Interfaces: Protocols like I2C, PMBus, or CAN allow for remote monitoring and control.

- Status Indicators: LEDs or display interfaces provide visual feedback on operational status.

- Fault Reporting: Capability to log and report various fault conditions for diagnostics.

Advancements in Power Supply PCBA Technology

High-Frequency Designs

The push for smaller, more efficient power supplies has led to advancements in high-frequency design:

- GaN and SiC Devices: Integration of Gallium Nitride and Silicon Carbide semiconductors allows for higher switching frequencies and improved efficiency.

- Planar Magnetics: Flat, PCB-integrated transformers and inductors enable lower profile designs with improved thermal performance.

- Resonant Topologies: Implementation of LLC and other resonant converter designs reduces switching losses and EMI.

Smart Power Management

Integration of intelligent features enhances the capabilities of power supply PCBAs:

- Adaptive Voltage Scaling: Dynamically adjusts output voltage based on load conditions to optimize efficiency.

- Power Sequencing: Manages the startup and shutdown sequence of multiple power rails for complex systems.

- Predictive Maintenance: Utilizes data analytics to predict potential failures and schedule maintenance.

Enhanced Thermal Management

Innovative approaches to thermal management improve reliability and power density:

- Advanced PCB Materials: Utilization of high thermal conductivity substrates like insulated metal substrate (IMS) PCBs.

- Embedded Heat Spreading: Integration of heat spreading layers within the PCB stackup for improved thermal distribution.

- Active Cooling Solutions: Incorporation of smart fan control or liquid cooling interfaces for high-power applications.

Conclusion

Power supply PCBA boards are evolving rapidly, driven by demands for higher efficiency, smaller form factors, and smarter power management. As technology advances, these boards are becoming more than just power converters; they are intelligent power management systems capable of adapting to complex load requirements and environmental conditions. The integration of advanced features like GaN technology, digital control, and smart thermal management is pushing the boundaries of what's possible in power supply design.

Precision Power Supply PCBA Manufacturer Since 2008 | Ring PCB

Ring PCB Technology Co., Limited stands as your premier PCB Manufacturing Partner since 2008. Our expertise in high-density stack-up PCBs, featuring 2-48 layers with advanced vias and tight tolerances, is ideal for cutting-edge applications. Our smart manufacturing facility, equipped with state-of-the-art technology, ensures top-quality production adhering to IPC-6012 Class 3 standards. We offer tailored solutions, from multi-layer designs to comprehensive PCBA services, leveraging our advanced Shenzhen factory. With 17 years of excellence, we deliver innovative, reliable PCB & PCBA solutions across diverse industries.

Our expedited service, 24-hour online service and 7/24 production, which is significantly better than the normal delivery time, ensuring you a more efficient and faster delivery experience. For businesses looking to stay at the forefront of power supply technology, partnering with experienced manufacturers is crucial. If you're seeking cutting-edge power supply PCBA solutions, don't hesitate to reach out to us at [email protected] for expert guidance and customized solutions.

References

1. Brown, M. (2021). "Advanced Power Supply Design: Principles and Applications". IEEE Press.

2. Zhang, L., & Chen, D. (2020). "High-Efficiency Power Supply PCBA: Recent Advancements and Future Trends". Journal of Power Electronics, 19(3), 678-690.

3. Rashid, M. H. (2019). "Power Electronics Handbook". Butterworth-Heinemann.

4. Lee, F. C., & Li, Q. (2018). "High-Frequency Power Conversion: GaN and SiC Devices in PCBA Design". IEEE Transactions on Power Electronics, 33(1), 35-47.

5. Smith, J. R., & Johnson, E. T. (2022). "Thermal Management Strategies in Modern Power Supply PCBAs". Thermal Science and Engineering Progress, 28, 100520.

Welcome to Ring PCB! Share your inquiry, and receive a tailored quotation!

Ring PCB, your trusted partner for PCB & PCBA Full Turnkey Solutions