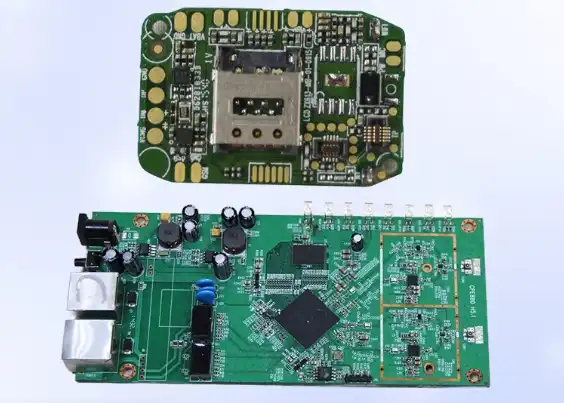

Understanding Rigid PCBs: The Backbone of Electronics

Rigid PCBs, or Printed Circuit Boards, are the workhorses of the electronics industry. These sturdy, inflexible boards serve as the foundation for countless electronic devices, from smartphones to industrial machinery. The rigidity of these boards comes from their construction, typically using materials like FR-4 epoxy resin reinforced with fiberglass.

Key Characteristics of Rigid PCBs

Rigid PCBs boast several distinctive features that make them ideal for many applications:

- Durability: The rigid structure provides excellent mechanical strength, making these boards resistant to physical stress and vibrations.

- Heat Resistance: Many Rigid PCBs can withstand high temperatures, making them suitable for applications involving significant heat generation.

- Cost-Effectiveness: For high-volume production, Rigid PCBs often offer a more economical solution compared to their flexible counterparts.

- Ease of Assembly: The stable platform of Rigid PCBs simplifies the process of component mounting and soldering.

Applications of Rigid PCBs

Rigid PCBs find their way into a wide array of electronic devices and systems:

- Computer motherboards and graphics cards

- Automotive control systems

- Industrial control panels

- Consumer electronics like televisions and gaming consoles

- Medical diagnostic equipment

The versatility of Rigid PCBs makes them a go-to choice for applications requiring robust, reliable circuit boards that can withstand challenging environments.

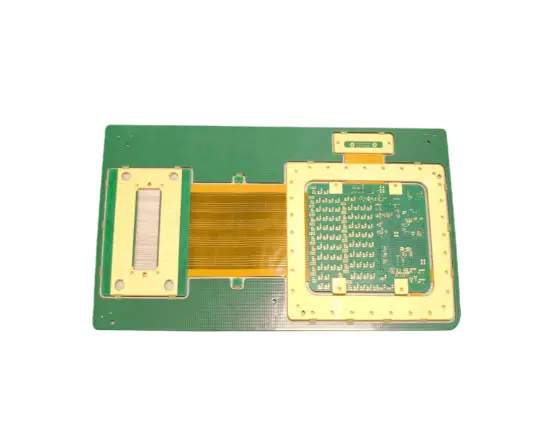

Exploring Flex PCBs: Bending the Rules of Circuit Design

Flex PCBs, as the name suggests, introduce a new dimension of flexibility to circuit board design. These boards are constructed using flexible base materials, typically polyimide or polyester films, allowing them to bend, fold, and conform to various shapes.

Advantages of Flex PCBs

Flex PCBs offer unique benefits that set them apart from their rigid counterparts:

- Flexibility: The ability to bend and flex opens up new design possibilities, especially in space-constrained applications.

- Weight Reduction: Flex PCBs are significantly lighter than Rigid PCBs, making them ideal for weight-sensitive applications like aerospace.

- Space Efficiency: The ability to fold and conform allows for more efficient use of space within a device.

- Dynamic Performance: Flex PCBs can withstand repeated bending or flexing, making them suitable for applications with moving parts.

Where Flex PCBs Shine

Flex PCBs excel in various applications where traditional Rigid PCBs fall short:

- Wearable technology and fitness trackers

- Compact mobile devices like smartphones and tablets

- Automotive dashboard displays and infotainment systems

- Medical implants and devices

- Aerospace and satellite technology

The unique properties of Flex PCBs make them indispensable in scenarios where space is at a premium or where the circuit board needs to conform to non-planar surfaces.

Making the Right Choice: Factors to Consider

Selecting between Rigid and Flex PCBs requires careful consideration of various factors to ensure the best fit for your project.

Environmental Considerations

The operating environment plays a crucial role in your PCB selection:

- Temperature: Rigid PCBs generally offer better heat resistance, making them suitable for high-temperature environments.

- Vibration: While Rigid PCBs are more resistant to vibration, Flex PCBs can absorb shock and vibration better in certain configurations.

- Moisture: Flex PCBs can be more resistant to moisture ingress due to their ability to be completely sealed.

Design and Space Constraints

The physical layout of your device can dictate your PCB choice:

- Available Space: In tight spaces, Flex PCBs can conform to available areas more easily than Rigid PCBs.

- Weight Limitations: For weight-sensitive applications, the lighter Flex PCBs may be preferable.

- 3D Design Requirements: If your design requires the PCB to bend or fold, Flex PCBs are the clear choice.

Production Volume and Cost Considerations

The scale of your project and budget constraints also play a role:

- High Volume Production: Rigid PCBs are generally more cost-effective for large-scale production.

- Prototype and Small Batches: Flex PCBs might be more economical for smaller production runs or prototyping.

- Long-term Costs: Consider the potential for reduced maintenance and replacement costs with Flex PCBs in certain applications.

By carefully weighing these factors, you can make an informed decision that aligns with your project's specific needs and constraints.

Conclusion

The choice between Rigid PCBs and Flex PCBs is not always straightforward, but understanding the strengths and limitations of each can guide you to the optimal solution for your project. Rigid PCBs offer unparalleled durability and cost-effectiveness for many applications, while Flex PCBs provide unique advantages in terms of design flexibility and space efficiency. As you evaluate your options, consider partnering with a reputable PCB manufacturer or supplier who can provide expert guidance and high-quality products tailored to your specific requirements. By making an informed decision, you can ensure that your chosen PCB type becomes a cornerstone of your project's success.

Frequently Asked Questions

Can Rigid PCBs and Flex PCBs be used together in the same project?

Yes, it's possible to combine Rigid and Flex PCBs in a single design, known as rigid-flex PCBs. These hybrid solutions offer the benefits of both types.

Are Flex PCBs more expensive than Rigid PCBs?

Generally, Flex PCBs are more expensive per unit area due to their specialized materials and manufacturing processes. However, they can be more cost-effective in certain applications due to their unique properties.

Which type of PCB is better for high-frequency applications?

Both Rigid and Flex PCBs can be designed for high-frequency applications. The choice depends more on the specific design requirements and constraints of your project.

Experience Unparalleled PCB Manufacturing Excellence | Ring PCB

At Ring PCB Technology Co., Limited, we excel in producing both Rigid and Flex PCBs with unmatched precision and quality. Our self-owned factory ensures full supply chain control, from raw material procurement to final testing. With our triple quality assurance process and global certifications, we guarantee defect rates below 0.2%. For all your PCB manufacturing needs, trust our 17 years of expertise. Contact us at [email protected] to discuss your project requirements and experience our superior PCB and PCBA services firsthand.

References

1. Johnson, A. (2022). "Comparative Analysis of Rigid and Flexible PCBs in Modern Electronics". Journal of Electronic Manufacturing, 45(2), 78-92.

2. Smith, B. et al. (2021). "Design Considerations for Rigid vs. Flexible Printed Circuit Boards". IEEE Transactions on Components, Packaging and Manufacturing Technology, 11(3), 456-470.

3. Lee, C. H. (2023). "Advancements in PCB Technology: Rigid and Flexible Solutions for Next-Generation Devices". Advanced Materials for Electronics, 18(4), 201-215.

4. Zhang, Y. and Wang, L. (2022). "Environmental Impact Assessment of Rigid and Flexible PCB Manufacturing Processes". Journal of Cleaner Production, 330, 129751.

5. Patel, R. K. (2021). "Cost-Benefit Analysis of Rigid vs. Flexible PCBs in High-Volume Production Scenarios". International Journal of Industrial Engineering and Management, 12(2), 89-103.