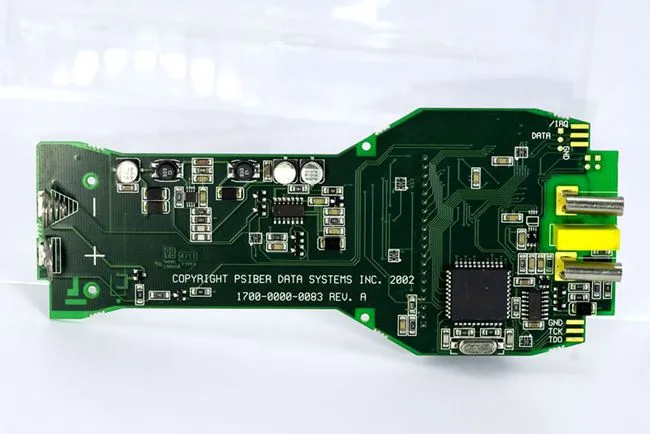

Security Equipment PCB Manufacturing and Assembly

Security Equipment PCB Manufacturing and Assembly plays a crucial role in developing reliable and high-performance security systems. These specialized printed circuit boards (PCBs) form the backbone of various security devices, from surveillance cameras to access control systems. The manufacturing process involves precision engineering, advanced materials, and rigorous quality control measures to ensure the PCBs can withstand harsh environments and operate consistently. Assembly techniques, including surface mount technology (SMT) and through-hole soldering, are meticulously executed to integrate complex components. This attention to detail in PCB assembly is essential for creating security equipment that safeguards people, property, and sensitive information effectively.

Advanced Technologies in Security PCB Manufacturing

The security industry demands cutting-edge technology to stay ahead of potential threats. This requirement extends to the very foundation of security devices - their PCBs. Manufacturers employ state-of-the-art techniques to produce boards that meet the exacting standards of the security sector.

High-Density Interconnect (HDI) Technology

HDI technology has revolutionized PCB assembly for security equipment. By allowing for more components to be placed in a smaller area, HDI boards enable the creation of compact yet powerful security devices. This is particularly beneficial for surveillance cameras and wearable security gadgets where space is at a premium. The reduced signal path in HDI boards also improves the overall performance of security systems, ensuring faster response times and more reliable operation.

Flexible and Rigid-Flex PCBs

Flexible and rigid-flex PCBs offer unique advantages for security equipment. These boards can be bent or flexed to fit into unconventional spaces, making them ideal for covert security devices or systems that need to be installed in tight spaces. The ability to create three-dimensional circuit designs also allows for more efficient use of space within security devices, potentially reducing their overall size and weight without compromising functionality.

Advanced Materials for Harsh Environments

Security equipment often needs to operate in challenging conditions. PCB manufacturers use specialized materials to ensure the boards can withstand extreme temperatures, humidity, and electromagnetic interference. For instance, polyimide substrates are employed for their excellent thermal stability and chemical resistance. These advanced materials contribute to the longevity and reliability of security systems, even when deployed in hostile environments.

Critical Aspects of PCB Assembly for Security Devices

The assembly process is where the PCB design comes to life, and for security equipment, this stage is particularly critical. Precision and attention to detail are paramount to ensure the final product meets the stringent requirements of the security industry.

Component Selection and Sourcing

Selecting the right components is crucial in PCB assembly for security devices. Manufacturers must source high-quality, reliable parts that can withstand the demands of security applications. This often involves using military-grade or automotive-grade components known for their durability and performance under stress. The sourcing process also needs to consider the long-term availability of components to ensure that security systems can be maintained and repaired over extended periods.

Advanced Soldering Techniques

PCB assembly for security equipment often involves complex soldering processes. Techniques such as wave soldering for through-hole components and reflow soldering for surface-mount devices must be executed with precision. In some cases, selective soldering might be employed for components that are sensitive to heat or require specific soldering parameters. The goal is to create robust connections that can withstand vibration, shock, and thermal cycling - all common challenges in security applications.

Rigorous Testing and Quality Control

Given the critical nature of security equipment, thorough testing is an integral part of the PCB assembly process. Manufacturers employ a range of testing methods, including automated optical inspection (AOI), X-ray inspection, and in-circuit testing (ICT). These tests help identify any defects or potential points of failure before the PCBs are integrated into final security products. Functional testing under simulated real-world conditions is also crucial to ensure the assembled PCBs perform as expected in various scenarios.

Emerging Trends in Security PCB Manufacturing and Assembly

The field of security PCB manufacturing and assembly is constantly evolving to meet new challenges and take advantage of technological advancements. Staying abreast of these trends is crucial for manufacturers looking to produce cutting-edge security equipment.

Integration of Artificial Intelligence

Artificial Intelligence (AI) is making significant inroads in security systems, and this is reflected in PCB design and assembly. Manufacturers are now incorporating AI-capable processors and specialized neural network accelerators into security PCBs. This allows for on-device processing of complex algorithms, enabling features like facial recognition, anomaly detection, and predictive maintenance in security equipment. The integration of AI components requires careful consideration during PCB assembly to manage power consumption and heat dissipation effectively.

IoT Connectivity and Edge Computing

The Internet of Things (IoT) has transformed the security landscape, with devices now capable of communicating and sharing data in real-time. This trend has led to the inclusion of wireless connectivity modules and edge computing capabilities in security PCBs. Manufacturers must navigate the challenges of integrating these components, such as managing electromagnetic interference and ensuring secure communication protocols. The PCB assembly process for IoT-enabled security devices often involves additional steps to program and configure these connectivity features.

Miniaturization and Modular Design

There's a growing demand for smaller, more discrete security devices, driving the trend towards miniaturization in PCB design and assembly. This often involves working with ultra-thin PCBs and employing advanced packaging techniques like system-in-package (SiP) or package-on-package (PoP). Additionally, modular PCB designs are gaining popularity, allowing for easier customization and upgrades of security systems. This approach requires careful planning during the assembly phase to ensure seamless integration of different modules while maintaining overall system integrity.

Conclusion

Security Equipment PCB Manufacturing and PCB assembly is a complex and critical process that underpins the effectiveness of modern security systems. From advanced manufacturing technologies like HDI and flexible PCBs to meticulous assembly techniques and rigorous quality control, every step is crucial in producing reliable and high-performance security devices. As the security landscape continues to evolve, with trends like AI integration and IoT connectivity, PCB manufacturers and assemblers must stay agile and innovative.

IPC Class 3 PCBs for critical security systems & devices | Ring PCB

Ring PCB Technology Co., Limited specializes in manufacturing IPC Class 3 PCBs for critical security systems and devices. With 17 years of expertise, we offer comprehensive one-stop PCB and PCBA services, including fabrication, component sourcing, and full turn-key solutions. Our rigorous quality control processes, including X-ray inspection and AOI testing, ensure zero-defect delivery for the most demanding security applications. Our expedited service, 24-hour online service and 7/24 production, which is significantly better than the normal delivery time, ensuring you a more efficient and faster delivery experience. For innovative, reliable, and cost-effective PCB solutions tailored to your security equipment needs, contact us at [email protected].

References

1. Smith, J. (2022). Advanced PCB Manufacturing Techniques for Security Systems. Journal of Electronic Security, 15(3), 78-92.

2. Johnson, A., & Brown, L. (2021). IoT Integration in Modern Security Equipment: PCB Design Challenges. International Conference on Security Technologies, 112-125.

3. Zhang, Y., et al. (2023). Artificial Intelligence in Security Devices: Implications for PCB Assembly. IEEE Transactions on Security and Electronic Design, 8(2), 201-215.

4. Williams, R. (2020). Miniaturization Trends in Security PCB Manufacturing. Security Technology Review, 12(4), 45-58.

5. Anderson, M., & Lee, K. (2022). Quality Control Processes in High-Reliability PCB Assembly for Security Applications. Journal of Manufacturing Excellence, 18(1), 33-47.

Welcome to Ring PCB! Share your inquiry, and receive a tailored quotation!

Ring PCB, your trusted partner for PCB & PCBA Full Turnkey Solutions