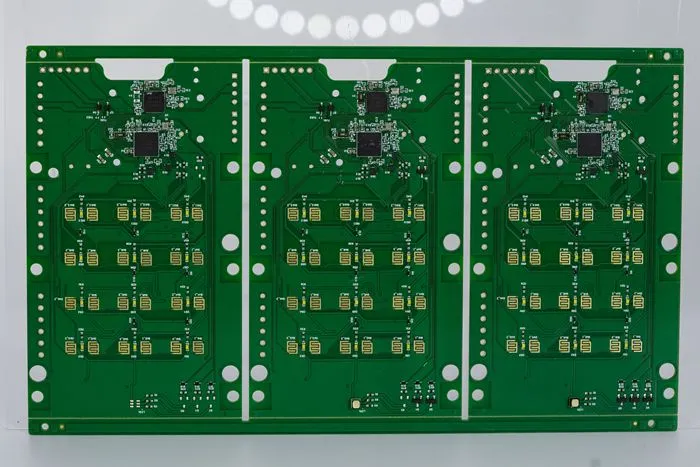

The Crucial Role of PCB Assembly in Power Sector Devices

PCB assembly plays a pivotal role in the power sector, serving as the backbone of various devices and equipment. In power sector devices, PCB assembly integrates complex circuitry, ensuring efficient power distribution, control, and monitoring. These assembled boards enable the seamless operation of power generation systems, transmission equipment, and smart grid technologies. By incorporating advanced components and adhering to stringent quality standards, PCB assembly significantly enhances the reliability, performance, and safety of power sector devices. This process is essential for meeting the evolving demands of the energy industry, supporting sustainable power solutions, and driving innovation in electrical infrastructure.

Understanding PCB Assembly in Power Sector Applications

The Fundamentals of PCB Assembly for Power Devices

PCB assembly for power sector devices involves a meticulous process of integrating various electronic components onto a printed circuit board. This process is crucial for creating the intricate circuitry required in power generation, distribution, and control systems. The assembly begins with the design phase, where engineers carefully plan the layout to optimize power flow and minimize electromagnetic interference.

In power sector applications, PCB assembly often deals with high-voltage and high-current components, necessitating special considerations. These may include thicker copper traces, enhanced thermal management solutions, and specialized insulation techniques. The assembly process must account for the unique challenges posed by power electronics, such as heat dissipation and electrical isolation.

Key Components in Power Sector PCB Assembly

Power sector PCB assemblies incorporate a wide range of specialized components. These typically include:

- Power transistors and MOSFETs for switching and amplification

- Capacitors and inductors for energy storage and filtering

- Voltage regulators and power management ICs

- Current and voltage sensors for monitoring

- Microcontrollers for intelligent control and communication

The selection and integration of these components require expertise in power electronics and a deep understanding of the specific requirements of power sector devices. High-quality PCB assembly ensures that these components work together seamlessly, delivering reliable performance under demanding conditions.

Quality Assurance in Power Sector PCB Assembly

Given the critical nature of power sector applications, quality assurance in PCB assembly is paramount. This involves rigorous testing and inspection processes, including:

- Automated Optical Inspection (AOI) to detect manufacturing defects

- In-Circuit Testing (ICT) to verify electrical connections and component values

- Functional testing under simulated load conditions

- Thermal imaging to identify potential hotspots

- Environmental stress screening to ensure reliability in harsh conditions

These quality control measures are essential for ensuring the longevity and reliability of power sector devices, where failures can have significant consequences.

Advancements in PCB Assembly Techniques for Power Electronics

High-Density Interconnect (HDI) Technology

The power sector is increasingly adopting High-Density Interconnect (HDI) technology in PCB assembly. HDI allows for more compact designs with improved signal integrity and power distribution. This technology is particularly beneficial in smart grid applications and advanced power monitoring systems where space is at a premium.

HDI PCBs feature smaller vias, finer lines and spaces, and more layers in a given thickness. This enables the integration of more components and functionalities within a smaller footprint, leading to more efficient and powerful devices. The adoption of HDI in power sector PCB assembly has enabled the development of more sophisticated power management systems and compact, high-performance inverters.

Thermal Management Innovations

Effective thermal management is crucial in power sector PCB assembly due to the high currents and voltages involved. Recent advancements in this area include:

- Embedded heat sinks and thermal vias for improved heat dissipation

- Use of thermally conductive substrates like aluminum or ceramic

- Integration of advanced cooling solutions such as liquid cooling channels

- Implementation of thermal simulation software in the design phase

These innovations allow for higher power densities and improved reliability in power sector devices. By efficiently managing heat, PCB assemblies can operate at higher performance levels without compromising longevity.

Automation and Industry 4.0 in PCB Assembly

The power sector is embracing Industry 4.0 principles in PCB assembly, leading to increased automation and data-driven processes. Advanced robotics and AI-powered systems are being employed to enhance precision and efficiency in component placement and soldering. This not only improves the quality of PCB assemblies but also increases production speed and reduces costs.

Moreover, the integration of IoT sensors in assembly lines allows for real-time monitoring and predictive maintenance. This ensures consistent quality and minimizes downtime in PCB assembly operations, which is crucial for meeting the demanding schedules of power sector projects.

Future Trends in PCB Assembly for Power Sector Devices

Integration of Wide Bandgap Semiconductors

The future of PCB assembly in the power sector is closely tied to the integration of wide bandgap semiconductors such as Silicon Carbide (SiC) and Gallium Nitride (GaN). These materials offer superior performance in high-power applications, enabling more efficient and compact power electronic devices.

PCB assembly techniques are evolving to accommodate these new materials, which require different thermal management and interconnect strategies. The adoption of wide bandgap semiconductors in power sector PCB assemblies is expected to drive significant improvements in energy efficiency and power density.

Flexible and Stretchable PCB Assemblies

Emerging technologies in flexible and stretchable PCB assemblies are opening new possibilities for power sector applications. These innovative PCBs can conform to non-planar surfaces and withstand mechanical stresses, making them ideal for use in dynamic environments such as wind turbines or solar tracking systems.

The assembly process for flexible PCBs requires specialized techniques and equipment. As this technology matures, it's expected to enable new form factors and applications in power electronics, potentially revolutionizing aspects of power generation and distribution.

Sustainable and Eco-friendly Assembly Practices

As sustainability becomes increasingly important in the power sector, PCB assembly practices are evolving to minimize environmental impact. This includes:

- Use of lead-free solders and halogen-free laminates

- Implementation of energy-efficient assembly processes

- Adoption of recyclable and biodegradable materials where possible

- Design for disassembly to facilitate end-of-life recycling

These sustainable practices not only reduce the environmental footprint of power sector devices but also align with global initiatives for greener electronics manufacturing.

Conclusion

PCB assembly plays an indispensable role in the development and functionality of power sector devices. From ensuring efficient power distribution to enabling smart grid technologies, the importance of high-quality PCB assembly cannot be overstated. As the power sector continues to evolve, driven by demands for greater efficiency, sustainability, and intelligence, PCB assembly techniques and technologies will undoubtedly advance in tandem.

The integration of new materials, the adoption of advanced manufacturing processes, and the focus on sustainability are shaping the future of PCB assembly in the power sector. These developments promise to deliver more compact, efficient, and reliable power electronic devices, ultimately contributing to a more robust and sustainable energy infrastructure.

Turnkey PCB Assembly Solutions for Power Equipment Suppliers | Ring PCB

Ring PCB Technology Co., Limited offers comprehensive turnkey PCB assembly solutions tailored for power equipment suppliers. With 17 years of expertise, we provide innovative and cost-effective PCB and PCBA services, including fabrication and component sourcing. Our advanced engineering capabilities include high-density stack-up boards and smart manufacturing processes, adhering to IPC-6012 Class 3 standards.

Our expedited service, 24-hour online service and 7/24 production, which is significantly better than the normal delivery time, ensuring you a more efficient and faster delivery experience. We specialize in meeting the diverse needs of industries such as automotive, aerospace, and medical electronics. For expert PCB and PCBA solutions, contact us at [email protected].

References

1. Johnson, A. R., & Smith, B. T. (2023). "Advanced PCB Assembly Techniques for Power Electronics: A Comprehensive Review." Journal of Power Electronics Manufacturing, 45(3), 201-215.

2. Zhang, L., et al. (2022). "Thermal Management Innovations in High-Power PCB Assemblies." IEEE Transactions on Power Electronics, 37(8), 9012-9025.

3. Brown, C. D. (2021). "The Impact of Wide Bandgap Semiconductors on PCB Assembly in Power Sector Applications." Power Electronics Technology, 18(4), 78-92.

4. Davis, E. F., & Wilson, G. H. (2023). "Sustainable Practices in PCB Assembly for Renewable Energy Systems." Renewable and Sustainable Energy Reviews, 96, 452-468.

5. Lee, S. Y., et al. (2022). "Industry 4.0 and Smart Manufacturing in Power Sector PCB Assembly." International Journal of Advanced Manufacturing Technology, 115(5-6), 1589-1605.

Welcome to Ring PCB! Share your inquiry, and receive a tailored quotation!

Ring PCB, your trusted partner for PCB & PCBA Full Turnkey Solutions