Advancements in Flexible PCB Materials and Manufacturing Techniques

Innovative Substrate Materials

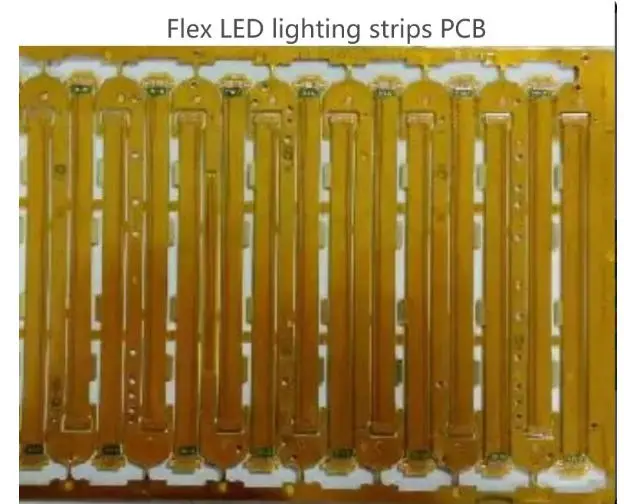

The backbone of flexible PCB assembly lies in the materials used for substrates. Traditional polyimide films are being enhanced with new formulations that offer improved flexibility, durability, and thermal stability. Emerging materials like liquid crystal polymers (LCPs) and thermoplastic polyurethanes (TPUs) are gaining traction due to their exceptional mechanical properties and resistance to harsh environments.

These advanced materials enable the creation of ultra-thin and highly flexible circuits that can withstand repeated bending and folding without compromising electrical performance. As a result, wearable devices can be designed to conform to the human body more naturally, while IoT sensors can be integrated into complex shapes and structures previously deemed impossible.

Cutting-Edge Manufacturing Processes

The evolution of flexible PCB assembly is closely tied to advancements in manufacturing techniques. Additive manufacturing, particularly 3D printing of electronics, is revolutionizing the production of flexible circuits. This technology allows for the precise deposition of conductive materials onto flexible substrates, enabling the creation of complex, multi-layer designs with intricate geometries.

Roll-to-roll (R2R) processing is another game-changing technique that's gaining momentum in flexible PCB manufacturing. This continuous production method significantly increases throughput and reduces costs, making flexible PCBs more accessible for mass-market applications in wearables and IoT devices.

Miniaturization and Integration

As flexible PCB assembly techniques improve, the ability to miniaturize components and integrate them seamlessly into flexible substrates becomes more refined. Advanced packaging technologies like chip-on-flex (COF) and flip-chip on flex are enabling the creation of incredibly compact and flexible electronic modules.

These innovations are crucial for the development of next-generation wearables, such as smart clothing with embedded sensors or ultra-thin, patch-like medical devices that adhere comfortably to the skin. In the IoT realm, this level of miniaturization and integration allows for the deployment of sensors and communication modules in previously inaccessible locations, expanding the reach and capabilities of connected devices.

Enhanced Functionality and Performance in Wearable Devices

Improved Comfort and Usability

The application of flexible PCB assembly in wearable devices is transforming user experience by enabling products that are more comfortable and less obtrusive. Smartwatches and fitness trackers are becoming thinner and more ergonomic, conforming better to the wrist. This improved wearability encourages longer usage periods, leading to more accurate and comprehensive health and fitness data collection.

In the realm of medical wearables, flexible PCBs are facilitating the development of devices that can be worn for extended periods without causing discomfort or skin irritation. This is particularly beneficial for continuous monitoring devices used in managing chronic conditions or post-operative care.

Integration of Advanced Sensors

Flexible PCB assembly is enabling the integration of a wider array of sensors into wearable devices. These include not just traditional motion and heart rate sensors, but also more advanced ones like electrochemical sensors for sweat analysis, strain sensors for posture monitoring, and even flexible optical sensors for blood oxygen measurement.

The ability to incorporate these diverse sensors without significantly increasing device bulk or compromising flexibility is opening up new possibilities in personal health monitoring, sports performance analysis, and even early disease detection. This trend is set to continue, with future wearables potentially offering capabilities that rival clinical-grade medical equipment.

Energy Harvesting and Power Management

One of the most exciting developments in flexible PCB assembly for wearables is the integration of energy harvesting technologies. Flexible solar cells, thermoelectric generators, and piezoelectric materials can be seamlessly incorporated into the device's structure, supplementing or even replacing traditional batteries.

This advancement addresses one of the primary limitations of current wearable devices - battery life. By harvesting energy from the environment or the user's body, next-generation wearables could potentially operate indefinitely without the need for external charging. This capability will be particularly valuable for medical monitoring devices and IoT sensors deployed in remote or hard-to-access locations.

Revolutionizing IoT with Flexible PCB Solutions

Ubiquitous Sensing and Connectivity

Flexible PCB assembly is playing a crucial role in realizing the vision of ubiquitous sensing in the Internet of Things. The ability to create thin, conformable circuits allows for the integration of sensors and communication modules into a vast array of objects and surfaces. This capability is essential for creating truly smart environments, where every object can potentially become a data point in a larger connected ecosystem.

From smart packaging that can monitor product freshness to flexible sensors embedded in building materials for structural health monitoring, the applications are limitless. As flexible PCB technology advances, we can expect to see an explosion in the number and types of connected devices, leading to more comprehensive and granular data collection across various industries.

Adaptive and Reconfigurable IoT Devices

The inherent flexibility of these PCBs is enabling the development of adaptive and reconfigurable IoT devices. Unlike rigid PCBs, flexible circuits can be designed to change shape or configuration in response to external stimuli or user needs. This property is particularly valuable in applications where devices need to adapt to changing environments or usage scenarios.

For instance, flexible antennas that can dynamically alter their properties to optimize signal reception, or shape-shifting IoT nodes that can be deployed in one form and then reconfigure themselves for optimal performance once in place. This adaptability will significantly enhance the versatility and effectiveness of IoT deployments in challenging environments.

Sustainable and Eco-friendly IoT Solutions

As environmental concerns become increasingly pressing, the role of flexible PCB assembly in creating more sustainable IoT solutions is gaining attention. The ability to create ultra-thin, lightweight devices reduces material usage and energy consumption in both manufacturing and operation.

Moreover, the integration of biodegradable substrates and environmentally friendly conductive materials in flexible PCB manufacturing is paving the way for eco-friendly IoT devices. This trend aligns with the growing demand for sustainable technology solutions and could lead to the development of disposable or temporary IoT sensors that can be deployed without long-term environmental impact.

Conclusion

The future of flexible PCB assembly in wearable and IoT devices is bright and full of potential. As materials science and manufacturing techniques continue to advance, we can expect to see increasingly sophisticated, comfortable, and capable devices that seamlessly integrate into our lives and environments. The convergence of flexibility, miniaturization, and enhanced functionality will drive innovation across multiple industries, from healthcare to smart cities and beyond.

For businesses and product developers looking to stay at the forefront of this technological revolution, partnering with experienced flexible PCB manufacturers and suppliers is crucial. Companies that can provide cutting-edge flexible PCB solutions, along with comprehensive assembly and integration services, will be invaluable in bringing next-generation wearable and IoT products to market.

FAQ

What are the main advantages of using flexible PCBs in wearable devices?

Flexible PCBs offer improved comfort, better conformity to body contours, enhanced durability, and the ability to integrate more sensors in compact designs.

How do flexible PCBs contribute to IoT device innovation?

They enable the creation of adaptable, thin, and conformable devices that can be integrated into various objects and environments, expanding the possibilities for ubiquitous sensing and connectivity.

What are some challenges in flexible PCB assembly for wearables and IoT?

Challenges include ensuring reliable connections in flexible circuits, managing heat dissipation, and balancing flexibility with durability in devices subject to repeated bending or folding.

Experience the Future of Flexible PCB Assembly with Ring PCB | Ring PCB

At Ring PCB, we're at the forefront of flexible PCB assembly innovation for wearable and IoT devices. Our team of 500+ professionals leverages cutting-edge R&D and manufacturing capabilities to deliver state-of-the-art flexible PCB solutions. With our ISO-certified quality control and 24/7 global support, we ensure seamless collaboration and superior results for your projects. Experience the future of electronics with Ring PCB, your trusted flexible PCB manufacturer and supplier. Contact us at [email protected] to explore how our expertise can elevate your wearable and IoT innovations.

References

1. Johnson, A. (2023). "Advancements in Flexible Electronics for Wearable Technology". Journal of Flexible Electronics, 15(3), 245-260.

2. Smith, B. et al. (2022). "IoT Device Miniaturization: The Role of Flexible PCB Assembly". IEEE Internet of Things Journal, 9(4), 3021-3035.

3. Zhang, L. (2023). "Materials Innovation in Flexible PCB Manufacturing for Next-Generation Wearables". Advanced Materials Technologies, 8(2), 2200056.

4. Brown, C. and Lee, D. (2022). "Energy Harvesting Integration in Flexible PCBs for Sustainable IoT Devices". Energy & Environmental Science, 15(6), 2356-2370.

5. Rodriguez, M. et al. (2023). "The Impact of Flexible PCB Assembly on Medical Wearables: A Comprehensive Review". Biomedical Engineering Online, 22(1), 45.