Top 5 Fast Turn PCB Assembly Services for Urgent Projects

Product development timelines compress year after year. Engineering teams face relentless pressure to deliver functional prototypes faster while maintaining quality standards. A supplier delay of just three days can derail entire project schedules, push back investor demonstrations, or cause critical market window closures. Fast turn PCB assembly has evolved from a premium service into an essential capability that separates competitive manufacturers from obsolete ones. When your project faces urgent deadlines—whether launching a consumer product before holiday shopping seasons, demonstrating a prototype to venture capitalists, or replacing failed production units—the assembly partner you choose determines success or expensive failure.

Speed alone isn't enough; rapid turnaround must deliver reliability, precision, and full compliance with specifications. The wrong choice creates more problems than it solves: rushed assembly causing defects, communication breakdowns delaying approvals, or hidden fees destroying budgets. This guide examines the top five fast turn PCB assembly providers that balance speed, quality, and comprehensive service for urgent electronics projects across industries.

Ring PCB Technology Co., Limited - Your 24/7 Fast Turn Assembly Partner

Ring PCB Technology Co., Limited, headquartered in China with global service infrastructure, has delivered rapid PCB fabrication and assembly solutions since 2008. The company operates continuous 24/7 production lines supported by three-shift engineering and sales teams, enabling true round-the-clock collaboration regardless of client time zones. This operational model transforms fast turn PCB assembly from a rush service into a standard capability.

Core specifications span 1-48 layer PCB fabrication with comprehensive assembly services covering SMT, DIP, and mixed-technology builds. Ring PCB's component sourcing network accesses over 100,000 part numbers through authorized distributor relationships, eliminating procurement delays that cripple urgent projects. The full turnkey service encompasses bare board manufacturing, complete component procurement, precision assembly, functional testing, and box-build integration—streamlining what typically requires coordinating multiple vendors into a single, accountable partnership.

Certification credentials include ISO9001, ISO14001, ISO13485 (medical devices), IATF16949 (automotive), and UL certifications that demonstrate systematic quality management across diverse industry requirements. Annual production capacity exceeds millions of assemblies, with substantial export volume serving North American, European, and Asian markets. This scale provides resource flexibility that smaller operations cannot match when urgent projects arrive.

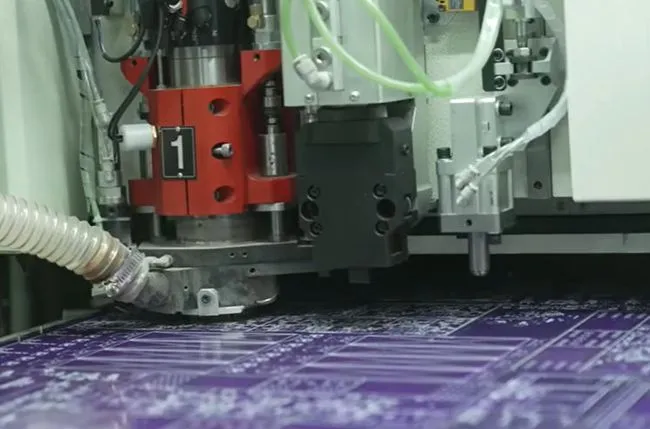

Technical advantages emerge from continuous equipment investment and process optimization. Advanced automated optical inspection (AOI) systems, X-ray inspection for complex packages (BGA, QFN), selective soldering equipment, and comprehensive testing capabilities ensure rapid assembly doesn't compromise quality. Ring PCB's 500+ professionals include dedicated R&D engineers who conduct Design for Manufacturing (DFM) reviews, identifying potential assembly issues before production begins. This proactive approach prevents delays from discovering problems mid-assembly—a common failure mode in rushed projects.

Typical customers span consumer electronics manufacturers racing to market windows, industrial equipment companies replacing failed legacy boards, medical device developers validating prototypes for regulatory testing, automotive electronics suppliers supporting just-in-time production schedules, and telecommunications equipment manufacturers launching network infrastructure upgrades. One automotive sensor client faced a production line shutdown when their previous assembler delivered defective boards. Ring PCB completed DFM review, sourced 47 components, assembled 500 boards, and delivered tested units within 72 hours—preventing a multi-day manufacturing halt that would have cost hundreds of thousands.

Innovation capability shows through intelligent automation integration that accelerates throughput without sacrificing precision. Ring PCB's investment in smart production equipment enables rapid changeover between different projects—critical for fast turn PCB assembly where small batches and varied designs define the workload. The company's quality defect rates consistently achieve levels below 50 PPM (parts per million), demonstrating that speed and quality aren't mutually exclusive when proper systems exist.

Advanced Circuits - U.S.-Based Rapid Prototyping Specialist

Advanced Circuits operates as a Colorado-based PCB manufacturer with strong capabilities in rapid turnaround prototyping and small-batch production. The company has built its reputation on quick-turn PCB fabrication and assembly services targeting U.S. customers who value domestic manufacturing for communication ease, IP protection, and logistics predictability.

Technical specifications emphasize rapid prototype capabilities with quoted lead times as short as 24 hours for bare boards and quick-turn assembly services for urgent projects. Advanced Circuits maintains domestic component inventory that reduces sourcing delays for common parts. The company's online quoting tools provide immediate pricing transparency, appealing to engineering teams working within fixed budgets. Quality certifications include ISO9001 and various military/aerospace approvals that demonstrate process maturity.

Customer base skews toward established U.S. companies, defense contractors requiring ITAR compliance, and startups prioritizing domestic manufacturing. The company's pricing generally runs higher than Asian competitors but delivers value through reduced shipping times, simplified communication (single time zone, native English speakers), and lower minimum order quantities. Advanced Circuits serves customers who calculate that domestic fast turn PCB assembly justifies premium pricing through faster iteration cycles and reduced project risk.

Geographic proximity benefits U.S. customers needing face-to-face consultations or rapid physical delivery. Projects requiring security clearances, export control compliance, or simply preferring domestic sourcing find Advanced Circuits a logical choice despite higher costs compared to offshore alternatives.

JLCPCB - High-Volume Automation at Aggressive Pricing

JLCPCB operates massive automated fabrication and assembly facilities in China, leveraging economies of scale to offer remarkably low pricing for fast turn PCB assembly. The company targets hobbyists, startups, and cost-conscious projects through aggressive pricing strategies that democratize access to professional assembly services.

Core capabilities emphasize high-volume production efficiency applied to small batch orders. JLCPCB's component library contains thousands of parts available for immediate assembly without sourcing delays. The streamlined online ordering platform appeals to tech-savvy customers comfortable with web-based workflows. Quoted lead times often range from 24 hours for fabrication to several days for complete assembly, with pricing significantly below Western competitors.

The company serves price-sensitive customers including makers, crowdfunding projects, startups validating concepts before major investments, and educational institutions. Component selection limitations—assembly relies heavily on parts already stocked in JLCPCB's inventory—can restrict design flexibility for specialized projects. Customer support operates primarily through ticketing systems rather than dedicated account management, which works for straightforward projects but may frustrate complex, urgent applications requiring real-time technical consultation.

JLCPCB excels for standardized projects using common components where cost minimization drives decisions. Complex assemblies requiring specialized components, extensive DFM consultation, or hands-on project management may encounter limitations that offset pricing advantages.

PCBWay - Integrated Prototyping Ecosystem for Startups

PCBWay positions itself as a comprehensive prototyping partner offering PCB fabrication, assembly, 3D printing, CNC machining, and injection molding services through an integrated platform. This ecosystem approach appeals to startups and product developers who need multiple manufacturing services coordinated efficiently.

The company operates facilities in China with global shipping infrastructure. Fast turn PCB assembly capabilities include SMT and through-hole assembly with typical lead times around 5-7 days for standard projects and expedited options for urgent needs. PCBWay's component sourcing accepts both customer-supplied parts and procurement services, providing flexibility for designs using specialized components outside standard inventory.

Technical support includes engineering review services, though depth varies based on project complexity. The company's online platform streamlines quoting, ordering, and project tracking—particularly valuable for distributed teams or remote startups lacking purchasing department infrastructure. Pricing sits between premium Western manufacturers and ultra-low-cost providers, targeting value-conscious customers willing to pay moderate premiums for broader service integration.

Customer demographics lean toward hardware startups, Kickstarter campaigns, university research projects, and small-to-medium enterprises. PCBWay's ability to handle mechanical enclosures alongside PCB assembly simplifies prototype development for products requiring both electronics and housings. The integrated service model reduces vendor coordination overhead that bogs down small teams with limited resources.

Quality consistency receives mixed reviews, with some customers reporting excellent results while others encounter communication challenges or quality variations. Projects with tight specifications benefit from detailed documentation, clear requirements, and proactive communication to ensure expectations align with delivered results.

MacroFab - Cloud-Based Manufacturing Platform

MacroFab offers a distinctive cloud-based approach to fast turn PCB assembly, operating as a manufacturing platform connecting customers with a distributed network of assembly facilities across the United States. This model provides flexibility and theoretical redundancy while introducing complexity compared to single-facility providers.

The platform emphasizes digital workflow management, allowing engineering teams to manage multiple projects, track builds, and coordinate revisions through web interfaces. Real-time visibility into production status appeals to remote teams and companies managing numerous concurrent projects. MacroFab handles component procurement, assembly coordination, and quality management through their platform, abstracting away the complexity of dealing directly with individual assembly houses.

Technical capabilities vary based on which network facility executes specific builds, though MacroFab maintains quality standards across partners. The distributed model can offer geographic advantages for customers wanting assemblies produced near final destinations, potentially reducing shipping time and costs. Lead times depend on facility availability and project complexity, typically ranging from several days to two weeks.

Target customers include U.S.-based companies preferring domestic manufacturing, teams comfortable with cloud-based workflows, and organizations managing complex multi-project portfolios. The platform approach introduces an additional layer between customer and physical manufacturing, which some find valuable for coordination and others see as distancing them from production realities.

Pricing generally reflects U.S. domestic manufacturing costs—higher than Asian alternatives but competitive within the domestic market. Companies valuing distributed risk, cloud-based project management, and domestic sourcing find MacroFab's model appealing despite premium pricing compared to direct offshore manufacturing relationships.

Conclusion

Selecting the optimal fast turn PCB assembly partner requires evaluating speed, quality, technical capability, communication responsiveness, and total cost beyond just quoted pricing. The five providers examined—Ring PCB, Advanced Circuits, JLCPCB, PCBWay, and MacroFab—each bring distinct strengths serving different customer priorities. Ring PCB Technology Co., Limited distinguishes itself through genuine 24/7 operations, comprehensive turnkey services eliminating multi-vendor coordination, extensive certifications spanning medical/automotive/general electronics, global support infrastructure, and 17 years of refined processes balancing rapid turnaround with uncompromising quality.

Whether your urgent project involves medical device validation, automotive production recovery, consumer product launch acceleration, or industrial equipment replacement, the assembly partner you choose directly impacts whether tight deadlines become successful launches or expensive failures. Ring PCB delivers the speed, expertise, capacity, and reliability that urgent projects demand without compromising the quality that final products require.

Where to Buy Fast Turn PCB Assembly Services?

Sourcing reliable fast turn PCB assembly requires evaluating provider capabilities, certifications, communication infrastructure, and proven execution under pressure. Ring PCB Technology Co., Limited has delivered rapid turnaround PCB fabrication and assembly since 2008, serving urgent projects across electronics, automotive, aerospace, medical, and telecommunications industries. Our 24/7 production operations—supported by three-shift engineering and sales teams—enable true continuous manufacturing that doesn't stop for weekends, holidays, or time zone differences.

Comprehensive services eliminate vendor coordination delays: PCB fabrication (1-48 layers), electronic component sourcing from authorized distributors, expert SMT and DIP assembly, functional testing, and complete turnkey solutions extending through box-build integration. Our 500+ professionals bring specialized expertise across R&D optimization, global sales support, customer service, and precision manufacturing backed by ISO9001, ISO14001, ISO13485, IATF16949, and UL certifications.

Ring PCB's component sourcing network accesses over 100,000 part numbers, preventing procurement delays that derail tight schedules. Advanced equipment—automated optical inspection, X-ray systems for complex packages, selective soldering, thermal management—ensures rapid assembly maintains quality standards. Our engineering team conducts Design for Manufacturing reviews, identifying potential issues before production begins and preventing mid-assembly delays.

Whether you need prototype assemblies in 24-48 hours, small-batch production within a week, or bridge production while ramping larger volumes, Ring PCB delivers fast turn PCB assembly without sacrificing reliability. Visit turnkeypcb-assembly.com to explore our comprehensive capabilities, review technical specifications, and examine case studies from successful urgent projects across diverse industries. Contact our team directly at [email protected] to discuss your specific timeline requirements, technical specifications, and quality expectations.

References

1. Coombs, Clyde F. "Printed Circuits Handbook: Fast Turn Manufacturing and Assembly Techniques, Seventh Edition." New York: McGraw-Hill Professional, 2016.

2. Institute for Printed Circuits. "IPC-A-610G: Acceptability of Electronic Assemblies - Standards for Fast Turn Production Environments." Bannockburn: IPC Publications, 2020.

3. Prasad, Ray P. "Surface Mount Technology: Principles and Practice for Rapid Prototyping and High-Volume Assembly, Third Edition." Boston: Springer, 2018.

4. Judd, Michael and Brindley, Keith. "Soldering in Electronics Assembly: Quality Standards for Quick-Turn Manufacturing." Oxford: Newnes Technical Books, 2019.

5. Brassard, Jean-Pierre. "Electronics Manufacturing Management: Optimizing Lead Times in PCB Assembly Operations." Boca Raton: CRC Press, 2021.

Welcome to Ring PCB! Share your inquiry, and receive a tailored quotation!

Ring PCB, your trusted partner for PCB & PCBA Full Turnkey Solutions