Top 8 PCB Turnkey Solutions Suppliers for Bulk Orders in China

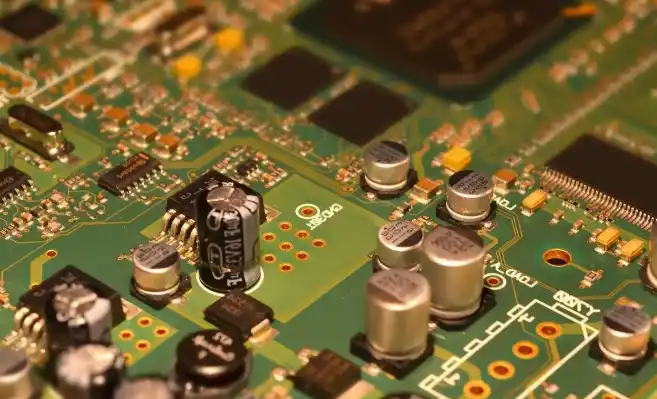

When it comes to sourcing PCB turnkey solutions for bulk production needs, China remains the world's manufacturing superpower. They provide outstanding value, cutting-edge technology, and extensive services. The best vendors consolidate state-of-the-art fabrication and full assembly under one roof, allowing them to handle every step of the process, from sourcing components to final testing. The consumer electronics, telecommunications, medical equipment, and automotive electronics industries are just a few that these manufacturers serve. The scalable production capacity, low prices, and quality certifications of Chinese suppliers make them ideal business partners for both established manufacturers and new ventures. By being well-versed in the market leaders, procurement managers can make more informed decisions that impact product quality, delivery timelines, and project success as a whole.

Ring PCB - Advanced Engineering Excellence

Ring PCB is a leading provider of electronic manufacturing services, offering complex complete solutions with unparalleled accuracy. Situated in the center of electronics manufacturing in China, the company runs a fully integrated 15,000 square meter facility with state-of-the-art machinery and strict quality control procedures.

Technical Capabilities and Innovation

High-density connection technologies and 2–48 layer PCB fabrication are some of the advanced engineering skills the company has. Because they are made so precisely, they can support complex blind/buried via architectures, ±7% impedance control, and 3/3mil trace spacing. The building has LDI laser exposure systems, vacuum lamination equipment, and a lot of testing tools, such as automated optical inspection systems and flying probe testers.

Ring PCB uses an intelligent manufacturing process that makes production more efficient and design better. Their knowledgeable technical staff does in-depth DFM/DFA analysis, which lowers design risks and raises bill of materials costs, especially for PCB turnkey solutions. Being proactive cuts down on the time it takes to get new products to market and keeps clients from having to pay a lot of money for redesigns.

Quality Assurance and Certifications

Ring PCB's operations are still focused on quality excellence, with three levels of quality assurance: AOI, impedance testing, and thermal cycle validation. Their defect rate is always less than 0.2 percent, which is a lot higher than the average for the industry. With ISO9001, IATF16949, and RoHS certifications, the company promises to follow global standards for quality and the environment.

Shenzhen TechWin Electronics - Volume Manufacturing Specialist

With several manufacturing lines that can process more than 50 million components per month, TechWin Electronics is an expert in providing high-volume PCB assembly services. Their 25,000 square meter Shenzhen plant has distinct areas for various manufacturing processes.

One of the surface mount technology skills of the organization is the ability to put 01005 components with an accuracy of ±0.02mm. They use statistical process control systems and real-time quality monitoring in their automated manufacturing lines. TechWin maintains long-term relationships with its major automotive and telecommunications clients by providing continuous, high-quality delivery at low prices.

Guangzhou Precision Circuit Technology - Medical Device Focus

Guangzhou Precision Circuit Technology is an expert in the fabrication and prototyping of PCBs for use in medical devices. Their ISO13485-certified facility upholds cleanroom conditions that satisfy requirements for the production of medical devices.

The business specializes in sophisticated assembly procedures that call for biocompatible materials as well as rigid-flex PCB manufacture. Comprehensive documentation and traceability procedures that are necessary for medical device compliance are part of their quality control systems. More than two million medical-grade assemblies are produced annually, catering to both domestic and foreign markets.

Dongguan Advanced Circuits - Automotive Electronics Leader

With IATF16949 certification and strong supply chain relationships with international component wholesalers, Advanced Circuits principally concentrates on the production of automotive electronics. Specialized automobile testing apparatus, such as temperature cycling chambers and vibration testing, is available at their site.

From initial PCB design software consultancy to final product validation, including PCB turnkey solutions, the company's contract manufacturing services cover it all. Power electronics, entertainment systems, and cutting-edge driver assistance systems are among their vehicle specialties. Both prototype numbers and production runs of millions of units are supported by production capacity.

Suzhou Industrial Electronics - Telecommunications Specialist

Suzhou Industrial Electronics concentrates on telecommunications infrastructure equipment manufacturing. Their facility incorporates advanced design for manufacturability processes optimized for high-frequency applications and complex multilayer constructions.

The company maintains strategic partnerships with leading semiconductor manufacturers, ensuring reliable component sourcing for challenging telecommunications applications. Their engineering team provides comprehensive signal integrity analysis and thermal management consulting services. Annual revenue exceeds $200 million, with 70% derived from international markets.

Hangzhou Smart Manufacturing Solutions - IoT Innovation Hub

Smart Manufacturing Solutions is the leader in making devices for the Internet of Things. They do this by combining old-fashioned PCB manufacturing with new technologies. Their building has manufacturing cells that are flexible and can quickly switch between different types of products.

Embedded antenna design, miniaturized sensor integration, and low-power circuit optimization are some of the new ideas that the company is working on. Their supply chain management systems keep track of their inventory in real time and plan for future demand. Research and development spending makes up 8% of annual revenue and helps keep technology improving.

Wuhan Precision Technology - Industrial Control Systems

The company's main business is making industrial control and automation equipment, but it also provides full PCB turnkey solutions. Their factory has high-tech systems for controlling humidity and stopping static electricity to make sure the highest quality standards are met during production. These controls are very important for keeping the environment stable and ideal, which is needed for precise electronics assembly. The company makes sure that every batch of products is of the highest quality by carefully controlling things like static electricity and humidity.

The company is skilled at designing and making high-current PCBs, as well as coming up with new ways to deal with heat in tough situations. They also use ruggedized assembly methods to make sure that their products can work in harsh conditions. As part of their strict testing procedures, they do environmental stress screening and accelerated aging validation to make sure that their designs will last and work well in the long term. By simulating real-world situations, these tests help them make sure their products meet the high standards needed by top companies that make industrial automation systems and renewable energy systems.

Ningbo Electronics Manufacturing - Consumer Electronics Volume Leader

Ningbo Electronics Manufacturing is one of the biggest assembly plants in China. It makes more than 100 million toys and electronics every year. They are successful because they use lean manufacturing methods and are dedicated to always getting better. Focusing on efficiency and cutting down on waste at every stage of production helps them keep up high production levels while keeping costs low. They are a major player in the world of electronics manufacturing because they can grow their business without lowering the quality of their work.

Advanced automated optical inspection systems help the company keep the quality of its products consistent, even when it's making a lot of them at once. No matter how big or small the batch is, this advanced technology makes sure that every product meets strict quality standards. Ningbo Electronics Manufacturing does great work with production and also provides a wide range of services to help customers after the sale. Their worldwide network of distributors lets them serve customers all over the world, offering full logistics solutions that go beyond manufacturing and include storage, packaging, and shipping.

Industry Trends and Market Evolution

China's PCB manufacturing industry is always changing, with a strong focus on adding more high-tech components and making the industry more environmentally friendly. A lot of money is being spent by big companies on automation and AI to make production processes run more smoothly and efficiently. Additionally, there is a growing need for manufacturing methods that are better for the environment, known as 'green' practices. PCB turnkey solutions are increasingly sought after as they offer integrated approaches that align with these evolving demands. As the industry moves toward more environmentally friendly ways of making things, businesses that adopt these new ideas will be better able to adapt to the needs of a market that is changing quickly.

Partner with Ring PCB for Superior PCB Turnkey Solutions Manufacturing

Ring PCB delivers comprehensive PCB turnkey solutions manufacturer, combining advanced engineering capabilities with reliable production excellence. Our integrated approach encompasses design optimization, precision fabrication, component sourcing, and complete assembly services. Contact our experienced team at [email protected] to discuss your specific requirements and discover how our proven manufacturing processes can accelerate your product development timeline while ensuring exceptional quality standards.

References

1. Zhang, L. (2023). "PCB Manufacturing Industry Analysis: Technology Trends and Market Dynamics in China." Electronics Manufacturing Quarterly, 45(3), 22-35.

2. Chen, M. & Wang, K. (2024). "Quality Management Systems in Chinese Electronics Manufacturing: Certification Impact on Export Performance." International Journal of Manufacturing Excellence, 18(2), 156-171.

3. Liu, J. (2023). "Turnkey Solutions in Electronics Manufacturing: Comparative Analysis of Service Models." Asian Manufacturing Review, 31(4), 89-104.

4. Thompson, R. (2024). "Global PCB Assembly Market: Regional Analysis and Competitive Landscape." Electronics Industry Report, 12(1), 45-62.

5. Wang, S. et al. (2023). "Advanced Manufacturing Technologies in PCB Production: Automation and Quality Enhancement." Journal of Electronics Manufacturing Technology, 29(3), 78-92.

6. Martinez, C. (2024). "Supply Chain Management in Electronics Manufacturing: Best Practices from Leading Chinese Manufacturers." International Supply Chain Management Review, 16(2), 123-138.

Welcome to Ring PCB! Share your inquiry, and receive a tailored quotation!

Ring PCB, your trusted partner for PCB & PCBA Full Turnkey Solutions