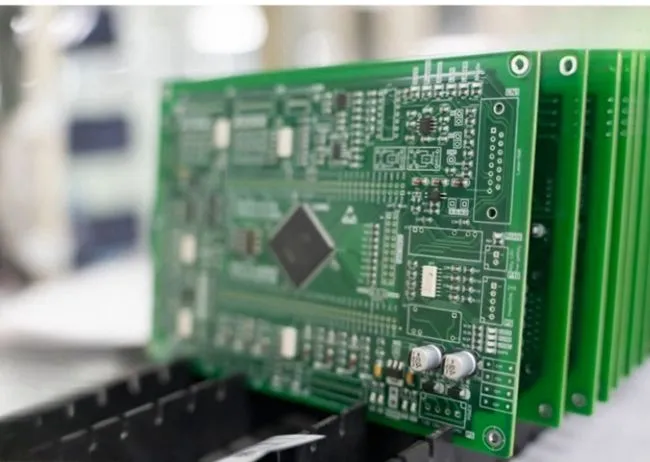

What is a PCB assembly?

PCB assembly, or Printed Circuit Board Assembly (PCBA), is the process of attaching electronic components to a bare printed circuit board (PCB) to create a functional electronic device. This intricate procedure involves soldering various components such as resistors, capacitors, integrated circuits, and connectors onto the PCB's surface or through-holes. The assembly process typically includes several stages: component placement, soldering, inspection, and testing. PCB assembly is a crucial step in electronics manufacturing, transforming a simple PCB into a complex, working electronic circuit that powers everything from smartphones to industrial machinery.

The PCB Assembly Process: From Bare Board to Functional Circuit

Preparing the PCB for Assembly

Before the assembly process begins, the bare PCB undergoes thorough inspection to ensure it meets quality standards. This includes checking for defects like scratches, copper traces integrity, and proper hole drilling. The board is then cleaned to remove any contaminants that could interfere with component adhesion or electrical connectivity.

Component Placement and Soldering Techniques

The next step in PCB assembly involves placing components on the board. This can be done manually for small-scale production or prototype runs, but is typically automated for larger volumes using pick-and-place machines. These machines precisely position surface-mount components onto the board with remarkable speed and accuracy.

Soldering is a critical aspect of PCB assembly. There are several soldering techniques used:

- Reflow Soldering: Commonly used for surface-mount components, this process involves applying solder paste to the board, placing components, and then heating the entire assembly in a reflow oven to melt the solder and create permanent connections.

- Wave Soldering: This method is primarily used for through-hole components. The PCB passes over a wave of molten solder, which adheres to exposed metal areas and component leads.

- Hand Soldering: For small production runs, prototypes, or repairs, technicians may use soldering irons to manually attach components.

Quality Control and Testing in PCB Assembly

After soldering, the assembled PCB undergoes rigorous quality control checks. These may include:

- Visual Inspection: Technicians or automated optical inspection (AOI) systems check for visible defects like misaligned components or solder bridges.

- X-ray Inspection: This non-destructive testing method allows inspection of hidden solder joints, particularly useful for ball grid array (BGA) components.

- In-Circuit Testing (ICT): Probes contact various points on the PCB to verify electrical connectivity and component values.

- Functional Testing: The assembled PCB is powered up and put through its paces to ensure it performs as intended in its final application.

Advanced Technologies in Modern PCB Assembly

Surface Mount Technology (SMT) vs. Through-Hole Technology

Surface Mount Technology (SMT) has revolutionized PCB assembly. SMT components are smaller and can be placed on both sides of the PCB, allowing for higher component density and smaller overall device size. This technology is now predominant in most electronic devices.

Through-hole technology, while older, is still used for components that require stronger mechanical bonds or need to handle higher power. Many PCB assemblies use a combination of SMT and through-hole components to leverage the advantages of both technologies.

Automated Assembly Lines and Industry 4.0

Modern PCB assembly facilities often feature highly automated production lines. These incorporate advanced robotics, conveyor systems, and real-time monitoring to achieve high throughput and consistency. The integration of Industry 4.0 principles brings further improvements:

- Internet of Things (IoT) Integration: Sensors throughout the assembly line collect data on machine performance, environmental conditions, and product quality.

- Big Data Analytics: The vast amount of data collected is analyzed to optimize processes, predict maintenance needs, and improve overall efficiency.

- Artificial Intelligence: AI algorithms can adjust assembly parameters in real-time based on data inputs, ensuring optimal quality and reducing waste.

Eco-Friendly and Sustainable PCB Assembly Practices

As environmental concerns grow, the PCB assembly industry is adopting more sustainable practices:

- Lead-Free Soldering: To comply with RoHS regulations, many manufacturers have switched to lead-free solder alloys.

- Energy-Efficient Equipment: Modern assembly lines use energy-saving features and optimized processes to reduce power consumption.

- Waste Reduction: Advanced planning and simulation tools help minimize material waste during production.

- Recyclable Materials: Some manufacturers are exploring the use of more easily recyclable materials in PCB construction.

Challenges and Future Trends in PCB Assembly

Miniaturization and High-Density Interconnect (HDI) Boards

The ongoing trend towards smaller, more powerful electronic devices presents challenges for PCB assembly. Components are becoming increasingly miniaturized, requiring extremely precise placement and soldering. High-Density Interconnect (HDI) boards, with their fine traces and microvias, demand advanced assembly techniques and equipment.

Flexible and Rigid-Flex PCB Assembly

Flexible and rigid-flex PCBs are gaining popularity in applications where space is at a premium or where the PCB needs to conform to a specific shape. Assembling these boards requires specialized handling and soldering techniques to avoid damaging the flexible substrate.

The Impact of 5G and IoT on PCB Assembly

The rollout of 5G networks and the proliferation of IoT devices are driving changes in PCB assembly:

- Higher Frequencies: 5G operates at much higher frequencies than previous cellular technologies, requiring careful control of signal integrity during assembly.

- Increased Complexity: IoT devices often integrate multiple functions (sensing, processing, communication) on a single board, increasing assembly complexity.

- Volume and Variety: The IoT boom is leading to a greater variety of PCB designs and higher production volumes, challenging assembly lines to be more flexible and efficient.

Conclusion

PCB assembly is a complex process that forms the backbone of modern electronics manufacturing. From the initial preparation of the bare PCB to the final testing of the assembled board, each step requires precision, expertise, and advanced technology. As electronic devices continue to evolve, becoming smaller, more powerful, and more interconnected, PCB assembly techniques and technologies must adapt to meet these new challenges. The industry's ongoing focus on automation, sustainability, and quality control ensures that PCB assembly will continue to play a crucial role in shaping our technological future.

One-stop solution from PCB design to assembly & test | Ring PCB

Ring PCB offers comprehensive PCB assembly solutions, leveraging advanced manufacturing equipment and expertise in high-layer count PCBs. Our one-stop service covers everything from component procurement to final assembly, ensuring quality and efficiency at every stage. With customized solutions, state-of-the-art facilities, and rigorous quality control, we're your ideal partner for PCB assembly projects. Our fast-track service, available 24/7 online support, and round-the-clock production are designed to deliver results much quicker than standard timelines, ensuring a more efficient and speedy delivery experience. Contact us at [email protected] to power your next innovation.

References

1. Coombs, C. F. (2019). Printed Circuits Handbook (7th ed.). McGraw-Hill Education.

2. Prasad, R. P. (2021). Surface Mount Technology: Principles and Practice (3rd ed.). Springer.

3. Hwang, J. S. (2018). Environment-Friendly Electronics: Lead-Free Technology. Electrochemical Publications.

4. Schillinger, K. (2020). PCB Design and Manufacturing Process. IEEE Press.

5. Zhang, G. (2019). Advanced Technology in PCB Assembly. Journal of Electronics Manufacturing, 24(3), 115-130.

Welcome to Ring PCB! Share your inquiry, and receive a tailored quotation!

Ring PCB, your trusted partner for PCB & PCBA Full Turnkey Solutions