German Electronics Manufacturing Services (EMS) businesses are increasingly turning to PCB Rapid Prototyping in China, attracted by its lower costs, shorter lead times, and deep pool of technical expertise, which together enable faster design validation, quicker iteration cycles, and more competitive electronics manufacturing outcomes. Chinese manufacturers send sample boards in 24 to 72 hours, while traditional European sources take 1 to 2 weeks. They do this while keeping high-quality standards by being certified by ISO9001 and IATF16949. By making this strategy change, German engineering teams can shorten the time it takes to create new products, ease the pressure of getting them to market faster, and stay competitive in high-demand electronics markets like cars, medical devices, and industrial automation systems.

Understanding the Competitive Landscape for EMS Companies

The way gadgets are made around the world has changed a lot, putting a lot of pressure on German EMS companies to improve their supply chain tactics. Shorter product lifecycles, high customer standards, and tough price competition from Asian markets are all problems that European makers are having to deal with. Because of how the market works, buying managers and production engineers have to come up with new ways to meet both quality standards and cost-cutting goals. German engineering is still unmatched, but making prototypes in Germany often hits problems that slow down the pace of progress.

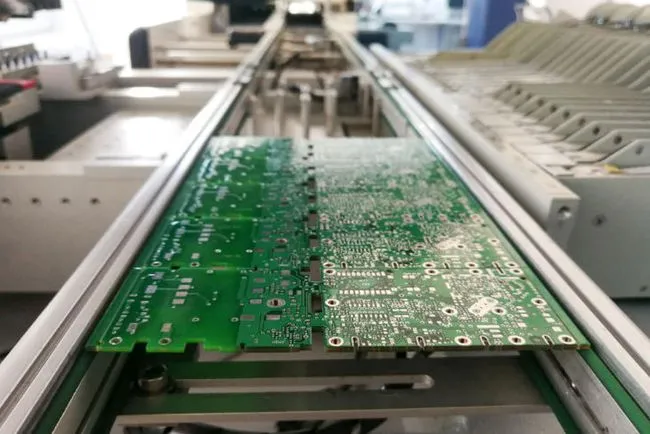

Most of the time, local providers don't have a lot of space for small-batch testing because they focus on making more big orders that bring in more money. This limitation has a big effect on startups and original design manufacturer (ODM) businesses that need manufacturing partners that can be flexible and meet different project requirements and tight delivery deadlines. China has become a world leader in modeling thanks to big investments in industrial facilities, robotic technologies, and training for skilled workers. The country's electronics environment supports full powers, from finding raw materials to final testing. This creates unique efficiency benefits that help foreign clients looking for reliable prototype development services.

Technical Capabilities That Drive German Partnerships

Chinese PCB makers have transformed the prototyping process by leveraging advanced manufacturing technologies within PCB Rapid Prototyping that meet strict German engineering standards, ensuring high precision, reliable performance, and fast turnaround times for demanding industrial and electronics applications. Modern factories have cutting-edge tools like LDI laser exposure systems, vacuum lamination chambers, and flying probe tests that ensure the exact manufacturing standards needed for complicated layered designs.

Because of these technological advances, complex boards can be made with up to 48 layers, 3 to 3 mil trace spacing, and impedance control settings within a 7% range. Automated processes make manufacturing more precise, which is directly related to important needs for high-density interconnect (HDI) designs that are common in 5G telecom equipment, car electronics, and medical devices. German engineers really like how thorough process tracking systems keep tight control of parameters throughout production routines so that the quality of the output is always the same.

Leading Chinese makers use quality assurance methods that go above and beyond industry standards by using multiple stages of proof. With automated optical inspection (AOI), X-ray analysis, and heat cycling tests, these facilities get flaw rates below 0.2%, which is a lot better than the average for the industry, which is less than 1%. These quality measures give German EMS companies faith in the stability of prototypes, which is important for the next step of design approval.

Cost-Effectiveness Without Quality Compromise

The main reason German companies choose Chinese prototype makers is to save money, but there are other cost benefits besides just saving money. Chinese providers use economies of scale to their advantage by integrating their supply lines, which lowers the cost of materials, improves inventory management, and speeds up transportation. These structural savings lead to competitive price structures that help German clients better divide their budgets among several sample versions.

Optimizing manufacturing costs is especially important for businesses that are making a lot of different versions of a product or doing a lot of design testing. Flexible minimum order numbers help German startups and small engineering teams stay within their budgets while still having access to professional-grade production capabilities. With this ease of access, advanced prototype technologies that were once only available to big companies with lots of money can be used by everyone. Chinese providers offer more than just low-cost production. They also offer full service packages that include design for manufacturability (DFM) advice, help finding parts, and choices for faster delivery. By avoiding expensive design changes and reducing delays in buying that could affect development plans, these value-added services lower the total cost of the project.

Speed and Flexibility Advantages

Chinese prototype makers differ from traditional European suppliers because they can deliver much faster turnaround times, enabling quicker iterations and shortened development cycles. This speed advantage makes PCB Rapid Prototyping in China especially attractive for companies seeking rapid validation, testing, and optimization of new electronic designs without compromising quality or technical accuracy. Orders for standard development services are usually finished in two to five business days, while orders for rapid services can produce simple designs in just 24 hours.

Because they are so quick, German engineering teams can stick to tight development plans without lowering the quality of design iterations. Modern electronics development requires factories to be able to adapt to different technology standards and changing project needs. Chinese suppliers can easily make mixed-technology systems with both surface-mount technology (SMT) and through-hole components. They can also handle multi-layer stackups with special materials and custom board designs that meet the needs of specific applications.

This flexibility is very helpful for German companies that are making new goods that push the limits of what is possible in design. German clients can change the order goals based on changing business needs or customer requests because production schedules are flexible. Leading makers keep extra capacity set aside for urgent projects. This way, they can make sure that important samples get processed first when market opportunities call for quick responses.

Quality Standards and Certification Compliance

International approval compliance is one of the most important things for German EMS companies to look for in partners who can make prototypes. Reliable Chinese providers have full quality management systems that are approved to ISO9001 standards. Facilities that focus on the automobile industry also get IATF16949 approval for using electronics in cars. These approvals make sure that the manufacturing processes meet the high standards for quality in Germany and the rules that must be followed by the government.

Chinese companies are taking steps to be more environmentally friendly. For example, they follow the rules for RoHS for dangerous substances and the rules for REACH for chemical safety. With these licenses, German businesses can stay in line with regulations in all of Europe's markets while also getting access to cheap manufacturing options. Each prototype package comes with quality paperwork such as thorough inspection reports, material certificates, and records of how the prototype was made. This information helps with internal quality assurance processes.

Leading Chinese factories use statistical process control methods, regular equipment testing plans, and operator training programs as part of their continuous improvement programs. These things keep the quality of the output constant. These organized ways of managing quality are fully in line with German engineering principles, ensuring that PCB Rapid Prototyping processes deliver consistent reliability, traceability, and precision throughout each stage of design validation and production.

Logistics and Communication Excellence

China and Europe are connected by efficient shipping networks that make it possible to send prototypes quickly and meet tight project deadlines. Shipping partnerships that have been around for a while offer a range of delivery choices, such as fast messenger services, combined packages, and special treatment for fragile electronic parts. German project managers can use advanced tracking systems to keep an eye on the progress of shipments and work with production teams to plan activities related to getting goods.

The communication infrastructure that supports business relationships between Germany and China has changed a lot. For example, many makers now hire expert staff who speak more than one language and use project management tools that allow teams to work together in real time. Digital platforms make it easy to share files, review designs, and check on the progress of orders, which makes it easier for people working on the same project in different time zones.

These tech solutions get rid of the old problems with communication and make processes that work well for projects with a lot of needs. Chinese providers can work with German business practices and conversation styles because they understand German culture through years of doing business internationally. This understanding of other cultures makes it easier to carry out projects and builds trust, which is important for long-term joint growth between German EMS companies and Chinese production partners.

Conclusion

German EMS companies leverage Chinese PCB rapid prototyping capabilities to maintain competitive advantages in demanding global markets through superior cost-effectiveness, technical excellence, and delivery speed. Strategic partnerships with certified Chinese manufacturers provide access to advanced manufacturing technologies, comprehensive quality assurance systems, and flexible production capabilities that support accelerated innovation cycles. The combination of competitive pricing, international certification compliance, and proven reliability makes Chinese prototyping services an essential component of successful German electronics development strategies. These partnerships enable German engineering excellence to flourish while optimizing resource allocation and time-to-market objectives in increasingly competitive electronics sectors.

Frequently Asked Questions

What turnaround times can German companies expect for prototype orders?

Standard prototyping services deliver completed boards within 2-5 business days, with expedited options available for simple designs within 24-48 hours. Complex multilayer boards with specialized materials may require 5-7 days, depending on technical specifications and current production schedules.

How do Chinese manufacturers ensure quality standards meet German engineering requirements?

Leading Chinese suppliers maintain ISO9001 and IATF16949 certifications with a comprehensive quality control system, including AOI testing, X-ray inspection, and thermal cycling validation. Defect rates typically achieve less than 0.2%, substantially better than industry averages through rigorous process monitoring and continuous improvement programs.

What technical capabilities are available for complex automotive and medical device prototypes?

Advanced manufacturing facilities support 2-48 layer boards with blind/buried vias, 3/3mil trace spacing, HDI configurations, and specialized materials for high-frequency applications. Comprehensive testing capabilities include impedance control verification, thermal shock testing, and functional validation protocols that meet automotive and medical device regulatory requirements.

Partner with Ring PCB for Advanced Prototype Manufacturing Solutions

Ring PCB delivers exceptional PCB rapid prototyping services specifically designed for German EMS companies seeking reliable, high-performance manufacturing partnerships. Our competitively priced solutions combine advanced technical capabilities with expedited service offerings that include 24/7 online support and continuous production 7 days a week, significantly outperforming standard delivery times to ensure efficient and faster delivery experiences for demanding projects.

Our state-of-the-art manufacturing facility produces sophisticated multilayer boards up to 48 layers with precision engineering that meets exacting German quality standards. International ISO certifications, including ISO9001 and IATF16,949, validate our commitment to quality excellence, while comprehensive testing protocols ensure zero-defect delivery for critical applications. As a leading PCB rapid prototyping manufacturer, we maintain vertical integration spanning raw material procurement through final testing, providing complete supply chain control that eliminates external dependencies.

Experience seamless collaboration through our digital procurement platforms that streamline order management, design review processes, and project communication workflows. Our engineering team provides comprehensive DFM optimization services that reduce design risks and minimize BOM costs while accelerating time-to-market objectives. Ready to transform your prototype development process? Contact us at [email protected] to discuss your specific requirements and discover how Ring PCB can enhance your competitive advantage through superior prototyping solutions.

References

1. Electronics Manufacturing Services Industry Report: German Market Analysis and Asian Supply Chain Integration Strategies, 2024

2. PCB Prototyping Technologies and Quality Standards in International Electronics Manufacturing, Journal of Electronics Production, 2023

3. Supply Chain Optimization for European EMS Companies: Cost-Benefit Analysis of Asian Manufacturing Partnerships, Industrial Engineering Review, 2024

4. Quality Certification Standards in Chinese Electronics Manufacturing: Impact on European Client Relationships, International Manufacturing Standards Quarterly, 2023

5. Rapid Prototyping Technologies and Market Trends in Global Electronics Development, Electronics Industry Analysis, 2024

6. German-Chinese Business Relationships in Electronics Manufacturing: Communication and Logistics Best Practices, Global Supply Chain Management, 2023