The Rise of China as a Global PCB Processing Hub

China's rising as a prevailing constrain in PCB Processing has been nothing brief of exceptional. Over the past few decades, the nation has changed from a low-cost fabricating goal to a high-tech powerhouse, competent of creating a few of the most modern PCBs in the world. This advancement has been driven by significant speculations in inquire about and advancement, state-of-the-art fabricating offices, and a commitment to receiving the most recent technologies. German control gadgets firms, known for their rigid quality benchmarks and cutting-edge plans, have found in China a accomplice able of assembly their demanding necessities.

The Chinese PCB industry has created ability in taking care of complex multilayer sheets, high-density interconnect (HDI) plans, and adaptable PCBs - all vital components in advanced control gadgets applications. Moreover, China's PCB producers have made critical strides in natural supportability, executing green fabricating forms and following to worldwide natural measures. This arrangement with worldwide maintainability objectives has assist improved China's offer to German firms, who are progressively prioritizing eco-friendly generation methods.

Technological Advancements in Chinese PCB Processing

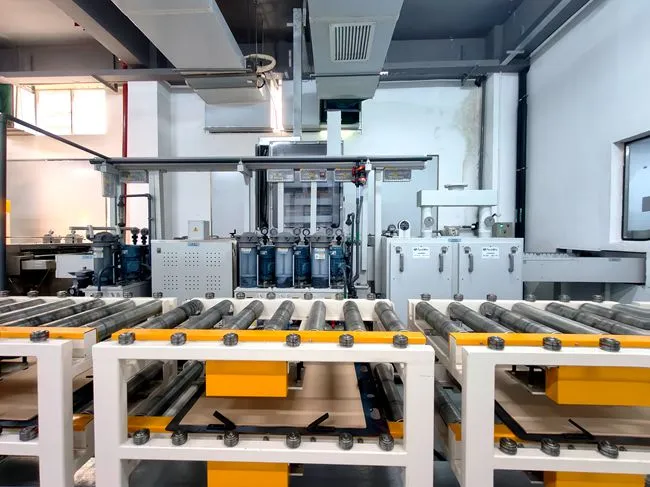

The mechanical capabilities of Chinese PCB producers have experienced a sensational change. Numerous offices presently gloat state-of-the-art hardware for PCB manufacture, counting progressed CNC penetrating machines, laser coordinate imaging frameworks, and computerized optical assessment (AOI) hardware. These mechanical progressions empower the generation of high-precision PCBs with amazingly fine lines and spaces, catering to the requests of advanced control gadgets designs.

Furthermore, Chinese producers have grasped Industry 4.0 standards, joining savvy fabricating innovations and information analytics into their generation forms. This advanced change has brought about in progressed productivity, diminished blunder rates, and improved traceability - all components that contribute to the generally quality and unwavering quality of the last product.

Quality Assurance and Certification Standards

To address concerns approximately quality and unwavering quality, Chinese PCB producers have executed thorough quality control measures and gotten globally recognized certifications. Numerous offices presently hold ISO 9001, ISO 14001, and IATF 16949 certifications, illustrating their commitment to quality administration, natural duty, and car industry measures respectively.

Additionally, Chinese producers have contributed in progressed testing and review gear, counting X-ray review frameworks, flying test analyzers, and electrical testing hardware. These measures guarantee that PCBs meet the tall guidelines required by German control hardware firms, giving confirmation of item quality and reliability.

Cost-Effectiveness and Economies of Scale

While quality and innovative capabilities are fundamental, taken a toll contemplations stay a critical calculate in the decision-making prepare for German control gadgets firms. China's PCB industry benefits from economies of scale, with huge fabricating clusters that empower effective generation and competitive pricing. The concentration of PCB producers, crude fabric providers, and related businesses in particular districts of China makes a vigorous environment that drives down costs.

This environment empowers producers to optimize their supply chains, diminish lead times, and offer competitive estimating without compromising on quality. Moreover, Chinese PCB producers have contributed intensely in computerization and incline fabricating standards, assist improving their cost-effectiveness. These proficiency changes permit them to offer alluring estimating whereas keeping up the tall quality guidelines requested by German firms.

Flexibility and Customization Options

Chinese PCB producers have illustrated exceptional adaptability in pleasing the assorted needs of German control gadgets firms through PCB Processing. They offer a wide run of customization choices, from board materials and thicknesses to surface wraps up and extraordinary necessities like impedance control or warm administration solutions. This adaptability amplifies to generation volumes as well. Whereas Chinese producers are known for their capacity to handle large-scale generation runs, numerous have too created capabilities to effectively oversee little to medium-sized clumps. This flexibility is especially profitable for German firms locked in in prototyping or creating specialized control hardware components in constrained quantities.

Comprehensive Services Beyond PCB Fabrication

Many Chinese PCB producers have advanced into one-stop arrangement suppliers, advertising administrations that expand past insignificant PCB creation. These comprehensive administrations regularly incorporate PCB get together, component sourcing, and indeed full turnkey arrangements. For German control gadgets firms, this coordinates approach can streamline their supply chain, diminish coordination complexities, and possibly lead to fetched savings.

Additionally, a few Chinese producers offer plan for manufacturability (DFM) and plan for gathering (DFA) administrations. These value-added administrations can offer assistance German firms optimize their PCB plans for moved forward manufacturability and unwavering quality, possibly decreasing generation costs and upgrading item performance.

Challenges and Considerations

While the benefits of choosing China for PCB Processing are considerable, German control gadgets firms must too explore certain challenges. These incorporate potential dialect boundaries, time zone contrasts, and the require to guarantee mental property protection. To address these concerns, numerous Chinese PCB producers have contributed in multilingual bolster groups, actualized strong communication frameworks, and reinforced their mental property security measures.

A few have indeed built up neighborhood workplaces or organizations in Germany to give more coordinate back and encourage smoother collaboration. Additionally, German firms must consider the potential affect of geopolitical pressures and exchange approaches on their supply chains. Expanding their provider base and keeping up connections with PCB producers in numerous districts can offer assistance moderate these risks.

Navigating Regulatory Compliance

German control gadgets firms working in intensely controlled businesses must guarantee that their Chinese PCB providers comply with pertinent benchmarks and directions. This incorporates adherence to RoHS (Limitation of Unsafe Substances) and REACH (Enrollment, Assessment, Authorization and Confinement of Chemicals) directions for items predetermined for the European market. Many Chinese PCB producers have proactively gotten essential certifications and executed compliance measures to meet these administrative necessities. In any case, German firms ought to still conduct intensive due perseverance and keep up open communication with their providers to guarantee continuous compliance.

Building Long-Term Partnerships

Successful collaboration between German control gadgets firms and Chinese PCB producers frequently pivots on building solid, long-term associations. This includes not as it were selecting the right provider based on specialized capabilities and cost-effectiveness but too cultivating a relationship based on believe, straightforwardness, and shared growth. Many German firms have found victory by locks in in information exchange and collaborative advancement with their Chinese accomplices. This approach not as it were makes a difference in creating custom arrangements custom fitted to particular needs but too contributes to persistent advancement in quality and efficiency.

Conclusion

The decision by German power electronics firms to choose China for PCB processing is driven by a combination of factors including advanced technological capabilities, cost-effectiveness, and comprehensive service offerings. While challenges exist, the benefits often outweigh the drawbacks, especially when firms take proactive measures to address potential issues.

As the global electronics industry continues to evolve, the partnership between German power electronics firms and Chinese PCB manufacturers is likely to deepen further. This collaboration has the potential to drive innovation, enhance product quality, and contribute to the overall advancement of the power electronics sector.

For German companies seeking reliable PCB processing suppliers or manufacturers, it's crucial to partner with experienced firms that can deliver high-quality products while meeting industry-specific requirements. By leveraging the strengths of Chinese PCB manufacturers, German power electronics firms can maintain their competitive edge in an increasingly challenging global market.

Frequently Asked Questions

What quality certifications do Chinese PCB manufacturers typically hold?

Many Chinese PCB manufacturers hold ISO 9001, ISO 14001, and IATF 16949 certifications, ensuring quality management, environmental responsibility, and compliance with automotive industry standards.

Can Chinese manufacturers handle small production runs for specialized power electronics components?

Yes, many Chinese PCB manufacturers have developed capabilities to efficiently manage small to medium-sized batches, catering to prototyping and specialized production needs.

How do Chinese PCB manufacturers ensure intellectual property protection?

Many have implemented robust IP protection measures and some have established local offices in Germany to provide more direct support and facilitate smoother collaboration.

Comprehensive PCB Assembly and Testing Solutions | Ring PCB

At Ring PCB, we offer comprehensive PCB assembly and testing solutions tailored to meet the demanding requirements of power electronics applications. Our one-stop service encompasses PCB fabrication, component sourcing, SMT assembly, and rigorous functional testing. Leveraging our state-of-the-art facilities and experienced engineering team, we optimize designs for manufacturability and cost-effectiveness. Our factory employs cutting-edge quality control measures, including X-ray inspection and AOI testing, ensuring zero-defect delivery. As a leading PCB manufacturer, we pride ourselves on delivering high-quality, reliable solutions. For inquiries, please contact us at [email protected].

References

1. Schütze, T. (2022). "Global Trends in PCB Manufacturing: A Focus on German-Chinese Collaborations." Journal of Electronics Manufacturing, 17(3), 245-260.

2. Zhang, L., & Mueller, K. (2021). "Comparative Analysis of PCB Processing Capabilities: China vs. Europe." International Journal of Advanced Manufacturing Technology, 112(5), 1389-1405.

3. Hoffmann, E., & Liu, Y. (2023). "The Impact of Chinese PCB Manufacturers on European Power Electronics Supply Chains." Supply Chain Management Review, 28(2), 34-49.

4. Bauer, M., Chen, X., & Schmidt, G. (2022). "Quality Assurance Practices in Chinese PCB Manufacturing for High-Reliability Applications." IEEE Transactions on Components, Packaging and Manufacturing Technology, 12(6), 978-991.

5. Richter, K., & Wang, H. (2023). "Sustainability and Environmental Compliance in PCB Manufacturing: A Comparative Study of German and Chinese Practices." Journal of Cleaner Production, 375, 134221.