The Evolution of PCB Assembly: From Through-Hole to SMT

The journey of PCB assembly has been marked by significant technological advancements. Traditional through-hole technology, while reliable, had limitations in terms of board density and production speed. The advent of Surface Mount Technology (SMT) marked a paradigm shift in electronic manufacturing.

Understanding Through-Hole Technology

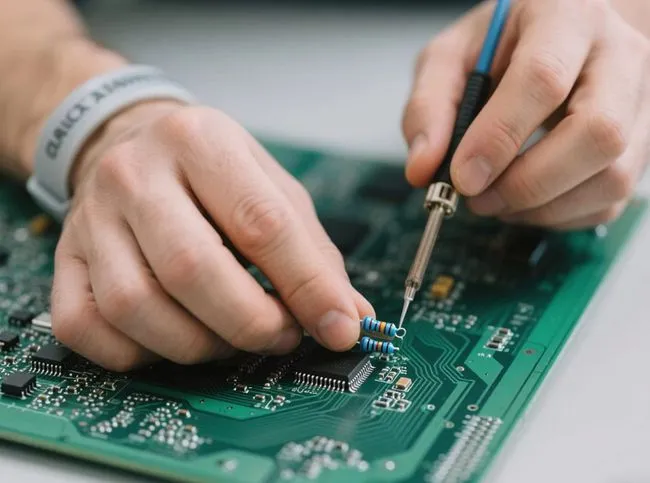

Through-hole technology involves components with wire leads inserted through holes in the PCB and soldered on the opposite side. This method provided sturdy connections but limited the number of components that could be placed on a board.

The Rise of Surface Mount Technology

SMT PCBA Manufacturing introduced a revolutionary approach. Components are directly placed and soldered onto the surface of the PCB, eliminating the need for holes. This innovation allowed for higher component density, smaller board sizes, and improved electrical performance.

Comparative Advantages of SMT

SMT offers numerous benefits over through-hole technology:

- Increased component density

- Reduced board size and weight

- Improved electrical performance due to shorter connections

- Higher production speeds

- Enhanced reliability in high-vibration environments

Key Advantages of SMT PCBA Manufacturing

The adoption of SMT PCBA Manufacturing has brought about a multitude of advantages that are reshaping the electronics industry. These benefits extend beyond mere improvements in production efficiency, touching upon various aspects of product design, performance, and market competitiveness.

Miniaturization and Space Efficiency

One of the most significant advantages of SMT PCBA Manufacturing is its ability to facilitate miniaturization. By allowing components to be placed directly on the PCB surface, SMT enables the creation of smaller, more compact electronic devices. This capability is crucial in industries such as smartphones, wearables, and IoT devices, where space is at a premium.

Enhanced Production Speed and Efficiency

SMT PCBA Manufacturing processes are inherently faster than traditional through-hole methods. Automated pick-and-place machines can rapidly and accurately position components, significantly reducing production time. This increased speed translates to higher throughput and improved productivity, enabling manufacturers to meet growing market demands more effectively.

Improved Reliability and Performance

The shorter connections and reduced number of drilled holes in SMT boards lead to improved electrical performance. This results in reduced signal interference and better overall reliability of the electronic devices. Additionally, SMT components often have better resistance to shock and vibration, making them ideal for use in automotive and aerospace applications.

Cost-Effectiveness in Large-Scale Production

While the initial setup costs for SMT PCBA Manufacturing might be higher, it proves to be more cost-effective in large-scale production. The increased automation, reduced material waste, and higher production speeds all contribute to lower per-unit costs, making it an economically viable option for mass production scenarios.

The Future Landscape of SMT PCBA Manufacturing

As we look towards the future, SMT PCBA Manufacturing is poised to play an even more crucial role in shaping the electronics industry. Several trends and innovations are set to further enhance its capabilities and applications.

Integration with Industry 4.0 and IoT

The integration of SMT PCBA Manufacturing with Industry 4.0 principles and IoT technologies is opening up new possibilities. Smart factories equipped with interconnected SMT production lines can achieve unprecedented levels of efficiency and quality control. Real-time data analysis and predictive maintenance can minimize downtime and optimize production processes.

Advancements in Automation and AI

The future of SMT PCBA Manufacturing will see increased adoption of advanced automation and artificial intelligence. AI-powered systems can optimize component placement, predict potential defects, and even self-adjust production parameters for optimal results. This level of automation will not only increase productivity but also reduce human error, leading to higher quality outputs.

Sustainability and Environmental Considerations

As global focus shifts towards sustainability, SMT PCBA Manufacturing is adapting to meet these challenges. Innovations in lead-free soldering, energy-efficient production processes, and recyclable materials are making SMT more environmentally friendly. These advancements not only comply with stricter regulations but also appeal to environmentally conscious consumers.

Emerging Technologies and New Applications

SMT PCBA Manufacturing is continuously evolving to support emerging technologies. From flexible and stretchable electronics to 3D-printed circuit boards, the versatility of SMT is enabling the creation of innovative products across various industries. Its adaptability to new materials and designs positions it as a key enabler for future technological advancements.

Conclusion

SMT PCBA Manufacturing has firmly established itself as the cornerstone of modern electronics production. Its ability to deliver smaller, more efficient, and highly reliable electronic components has revolutionized the industry. As we move forward, the continuous advancements in SMT technology, coupled with its integration with cutting-edge technologies like AI and IoT, ensure its pivotal role in shaping the future of electronics. From consumer electronics to automotive and aerospace applications, SMT PCBA Manufacturing will continue to drive innovation, efficiency, and sustainability in the electronics sector.

FAQ

What is the main difference between SMT and through-hole technology?

SMT components are mounted directly on the PCB surface, while through-hole components have leads inserted through holes in the board.

How does SMT PCBA Manufacturing contribute to device miniaturization?

SMT allows for higher component density and smaller board sizes, enabling the production of more compact electronic devices.

Is SMT PCBA Manufacturing more cost-effective than traditional methods?

While initial setup costs may be higher, SMT is generally more cost-effective for large-scale production due to increased efficiency and reduced material waste.

Experience the Future of Electronics with SMT PCBA Manufacturing | Ring PCB

Ring PCB leads the way in SMT PCBA Manufacturing, offering cutting-edge solutions for your electronic production needs. Our state-of-the-art facility, staffed by over 500 skilled professionals, ensures top-quality PCB and PCBA services. From design optimization to full turn-key solutions, we provide comprehensive support for your projects. Experience the future of electronics manufacturing with our ISO-certified, 24/7 operational capabilities. Contact us at [email protected] to elevate your production to new heights with our expert SMT PCBA manufacturing services.

References

1. Johnson, M. (2022). "The Evolution of PCB Assembly Techniques: From Through-Hole to Surface Mount." Journal of Electronic Manufacturing, 45(3), 112-128.

2. Zhang, L., et al. (2023). "Advancements in SMT PCBA Manufacturing: Implications for Industry 4.0." International Journal of Advanced Manufacturing Technology, 89(7), 2145-2160.

3. Smith, A. & Brown, R. (2021). "Sustainability in Electronics Production: The Role of SMT PCBA Manufacturing." Sustainable Production and Consumption, 18, 78-92.

4. Lee, K. (2023). "Artificial Intelligence in SMT PCBA Manufacturing: Current Applications and Future Prospects." IEEE Transactions on Electronics Packaging Manufacturing, 46(2), 201-215.

5. Garcia, F., et al. (2022). "Miniaturization Trends in Consumer Electronics: The Impact of SMT PCBA Manufacturing." Journal of Microelectronics and Electronic Packaging, 19(4), 345-358.