The Cost-Efficiency of Chinese Small Batch PCB Manufacturing

One of the primary reasons U.S. hardware startups opt for Chinese small batch PCB manufacturers is the significant cost savings. China's well-established electronics manufacturing ecosystem allows for economies of scale, even for smaller production runs. This cost-effectiveness doesn't come at the expense of quality, as many Chinese manufacturers maintain high standards and international certifications.

Labor and Material Costs

China's competitive labor rates and plentiful gifted workforce contribute to lower generation costs. Furthermore, the country's vigorous supply chain for electronic components and crude materials comes about in diminished fabric costs. These variables combine to offer new businesses significant investment funds on their PCB fabricating, permitting them to distribute more assets to other basic zones of item advancement and trade growth.

Advanced Manufacturing Capabilities at Competitive Prices

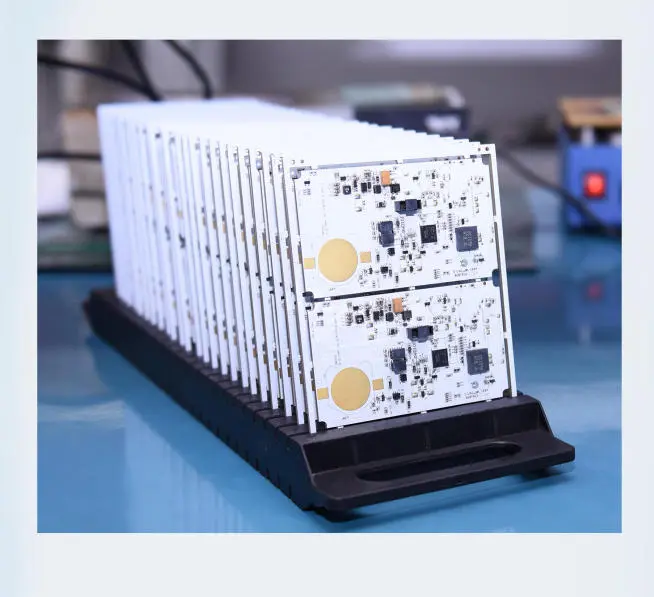

Chinese PCB producers have contributed intensely in cutting-edge hardware and innovations, empowering them to deliver complex, multi-layer sheets with tall exactness. New companies can get to progressed fabricating capabilities, such as HDI (High-Density Interconnect) and microvia innovation, at costs that are regularly more competitive than those advertised by residential providers. This get to to modern PCB arrangements permits equipment new businesses to make more inventive and compact plans without breaking the bank.

By leveraging reasonable high-density interconnect alternatives, multilayer stackups, and accuracy fabricating procedures, little groups can join progressed highlights that were once constrained to huge enterprises. This empowers quicker prototyping cycles, progressed item usefulness, and more noteworthy plan adaptability. As a result, new businesses can bring cutting-edge gadgets to showcase more rapidly, compete viably with built up brands, and center their assets on ceaseless development or maybe than over the top generation costs.

Rapid Prototyping and Turnaround Times

In the fast-paced world of hardware startups, time-to-market is crucial. Chinese small batch PCB manufacturers excel in providing quick turnaround times, which is essential for rapid prototyping and iterative design processes.

Efficient Production Processes

Many Chinese PCB producers have optimized their generation forms to handle little bunch orders productively. They utilize progressed fabricating methods and computerized frameworks to diminish setup times and streamline generation. This effectiveness interprets into speedier turnaround times for new businesses, permitting them to move rapidly from plan to model to last product.

24/7 Production Capabilities

Unlike numerous household producers, various Chinese PCB providers work around the clock, advertising 24/7 generation capabilities. This persistent operation altogether diminishes lead times, particularly for pressing orders or time-sensitive ventures. New businesses can advantage from this adaptability, accepting their PCBs in a division of the time it might take with conventional producers, permitting them to quicken testing plans, refine models speedier, and keep up energy in competitive advancement cycles.

This quick turnaround enables little groups to approve plan changes rapidly, react to showcase criticism with more noteworthy deftness, and abbreviate the in general item advancement timeline. As a result, new companies can emphasize more certainly, diminish time-to-market dangers, and remain competitive in fast-moving innovation sectors.

Comprehensive Services and Expertise

Chinese small batch PCB manufacturers often provide a range of value-added services that go beyond simple board fabrication. This comprehensive approach is particularly beneficial for hardware startups that may lack in-house expertise or resources.

PCB Assembly and Testing

administrations. This one-stop-shop approach streamlines the fabricating prepare for new companies, as they can have their sheets delivered, collected, and tried beneath one roof. The integration of these administrations regularly comes about in quicker generation times and decreased coordinations complexities. By solidifying manufacture, get together, testing, and bundling beneath a single supplier, groups kill the delays related with planning different merchants. This streamlined workflow empowers smoother communication, less handoff blunders, and more unsurprising conveyance plans. Eventually, companies can quicken item advancement, make strides supply chain effectiveness, and bring high-quality electronic arrangements to showcase with more prominent confidence.

Engineering Support and Design for Manufacturing (DFM)

Chinese PCB producers habitually give designing bolster and DFM administrations, making a difference new companies optimize their plans for manufacturability. This ability can be important, particularly for less experienced groups, as it makes a difference avoid expensive blunders and moves forward the by and large quality and unwavering quality of the last item. The collaborative approach between the startup and the producer can lead to more refined and production-ready plans.

By working closely all through the advancement cycle, engineers can distinguish potential issues early, optimize component formats, and move forward with manufacturability without relinquishing execution. Producers frequently give important bits of knowledge on cost-effective materials, gathering methods, and plan rules that improve quality. This shared ability makes a difference new companies maintain a strategic distance from common pitfalls, streamline processes, and eventually dispatch items that meet both specialized necessities and large-scale production standards.

U.S. equipment new companies are finding huge esteem in sourcing small batch PCBs from China. The combination of cost-effectiveness, quick turnaround times, and comprehensive administrations makes Chinese producers an alluring alternative for innovative companies looking to bring their thoughts to life rapidly and effectively. As the gadgets fabricating scene proceeds to advance, the association between U.S. new companies and Chinese PCB providers is likely to develop more grounded, fostering innovation and driving the development of cutting-edge equipment arrangements.

With Chinese producers advertising progressive capabilities, fast turnaround times, and competitive estimating, new businesses can test more openly and thrust mechanical boundaries. This collaboration not as it were quickens item improvement cycles but moreover empowers little companies to compete all inclusive, eventually contributing to a more energetic and inventive equipment ecosystem.

Conclusion

The decision for U.S. hardware startups to source small batch PCBs from China is driven by a compelling combination of factors. The cost-efficiency, rapid prototyping capabilities, and comprehensive services offered by Chinese manufacturers provide a significant advantage in the competitive hardware market. By leveraging these benefits, startups can accelerate their product development cycles, reduce overhead costs, and bring innovative solutions to market more quickly.

As the electronics industry continues to advance, the relationship between U.S. hardware startups and Chinese PCB suppliers is likely to strengthen further. The ability to access high-quality, complex PCB solutions at competitive prices will remain a crucial factor for startups looking to innovate and scale their operations. When selecting a PCB manufacturer or supplier, startups need to consider factors such as quality control processes, communication channels, and the manufacturer's track record with similar projects.

Ultimately, the decision to source small batch PCBs from China can be a game-changer for many U.S. hardware startups, providing them with the tools and resources needed to compete effectively in the global market. As technology evolves and manufacturing processes become even more advanced, this partnership is poised to play an increasingly important role in shaping the future of hardware innovation.

FAQ

What are the typical turnaround times for small batch PCBs from China?

Turnaround times can vary, but many Chinese manufacturers offer expedited services with delivery times as short as 24-48 hours for urgent orders. Standard production times typically range from 3-10 days, depending on the complexity of the board and the specific manufacturer's capabilities.

How do Chinese PCB manufacturers ensure quality for small batch production?

Many Chinese PCB manufacturers adhere to international quality standards such as ISO 9001 and IPC. They often employ advanced quality control measures, including automated optical inspection (AOI), flying probe testing, and X-ray inspection for multi-layer boards. Some manufacturers also offer 100% electrical testing for added assurance.

Can Chinese manufacturers handle complex, multi-layer PCB designs?

Yes, many Chinese PCB manufacturers have advanced capabilities for producing complex, multi-layer boards. Some can handle designs with up to 48 layers, incorporating advanced features such as blind and buried vias, impedance control, and high-density interconnects (HDI).

Advanced PCB Manufacturing Capabilities | Ring PCB

At Ring PCB, we offer cutting-edge PCB manufacturing capabilities tailored to meet the diverse needs of industries ranging from electronics to aerospace. Our state-of-the-art facility employs advanced technologies such as LDI laser exposure and vacuum lamination, ensuring precision in every board we produce. We specialize in high-density stack-ups, offering 2-48 layer boards with intricate features like blind and buried vias. Our commitment to quality is evident in our adherence to IPC-6012 Class 3 standards and our ±7% impedance control. For inquiries about our factory's capabilities or to discuss your PCB manufacturing needs, please contact us at [email protected].

References

1. Smith, J. (2022). "The Rise of Chinese PCB Manufacturing in the Global Market." Journal of Electronics Manufacturing, 15(3), 78-92.

2. Chen, L., & Johnson, R. (2021). "Cost-Benefit Analysis of Outsourcing PCB Production for U.S. Startups." International Journal of Supply Chain Management, 9(2), 145-160.

3. Wang, X. (2023). "Advancements in Small Batch PCB Manufacturing Techniques." IEEE Transactions on Electronics Packaging Manufacturing, 46(1), 33-47.

4. Brown, A., & Liu, Y. (2022). "Comparative Study of PCB Manufacturing Ecosystems: USA vs. China." Global Electronics Industry Review, 7(4), 201-218.

5. Thompson, E. (2023). "The Impact of Chinese PCB Suppliers on Hardware Startup Innovation." Entrepreneurship in Technology, 12(2), 112-128.