Grasping Aluminum PCBs and Their Heat Dissipation Properties

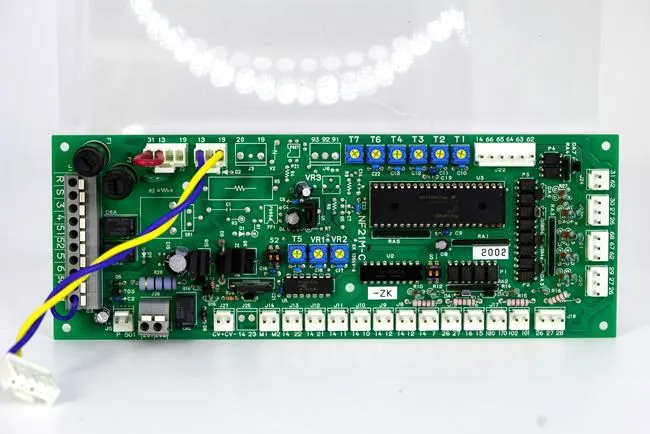

Aluminum PCBs, also known as metal core PCBs (MCPCBs), have gained significant popularity in various industries due to their exceptional heat dissipation capabilities. These specialized circuit boards feature a base layer of aluminum, which serves as an excellent conductor of heat, making them ideal for applications that generate high amounts of thermal energy.

The Structure of Aluminum PCBs

An aluminum PCB typically consists of three main layers:

- Aluminum Base: This layer forms the foundation of the PCB and is responsible for the majority of heat dissipation.

- Dielectric Layer: A thin, thermally conductive insulation layer that electrically isolates the circuit from the aluminum base.

- Copper Layer: The top layer where the circuit traces are etched, similar to traditional FR-4 PCBs.

This unique structure allows aluminum PCBs to efficiently transfer heat from the components to the aluminum base, which then dissipates it into the surrounding environment. The thermal conductivity of aluminum, combined with its lightweight nature, makes it an excellent choice for heat-sensitive applications.

Heat Dissipation Efficiency of Aluminum PCBs

Aluminum PCBs excel in heat dissipation due to several factors:

- High Thermal Conductivity: Aluminum has a thermal conductivity of about 237 W/mK, which is significantly higher than traditional FR-4 materials (0.3 W/mK).

- Uniform Heat Distribution: The aluminum base spreads heat evenly across the board, preventing hot spots and thermal stress.

- Reduced Thermal Resistance: The direct connection between components and the aluminum base minimizes thermal resistance.

- Enhanced Cooling Capacity: Aluminum PCBs can dissipate heat more efficiently, allowing for higher power densities and improved component reliability.

These properties make aluminum PCBs particularly suitable for LED lighting, power supplies, automotive electronics, and other high-power applications where thermal management is crucial.

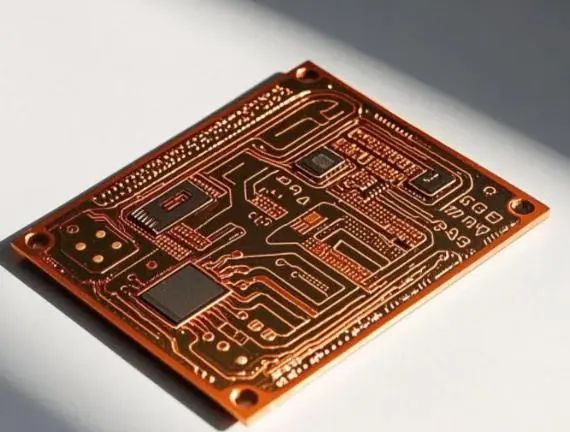

Copper Substrate PCBs: Thermal Performance and Applications

While aluminum PCBs are often the go-to choice for heat dissipation, copper substrate PCBs also offer unique advantages in certain applications. Understanding their thermal properties and use cases is essential for making informed decisions in PCB design.

Thermal Characteristics of Copper Substrate PCBs

Copper substrate PCBs leverage the excellent thermal conductivity of copper to manage heat in electronic circuits. Some key points to consider include:

- Superior Thermal Conductivity: Copper has a thermal conductivity of about 401 W/mK, which is higher than aluminum.

- Higher Density: Copper is denser than aluminum, which can be an advantage or disadvantage depending on the application.

- Electrical Conductivity: Copper's superior electrical conductivity can be beneficial in certain high-frequency applications.

- Cost Considerations: Copper is generally more expensive than aluminum, which can impact the overall cost of the PCB.

Applications and Use Cases for Copper Substrate PCBs

Copper substrate PCBs find their niche in specific applications where their unique properties offer advantages:

- High-Frequency RF Applications: The excellent electrical properties of copper make it suitable for radio frequency circuits.

- Extreme Temperature Environments: Copper's stability at high temperatures can be advantageous in certain industrial or aerospace applications.

- Power Electronics: In some high-power applications, the superior thermal conductivity of copper can be leveraged for efficient heat management.

- Specialized Military and Aerospace Use: Where the additional weight of copper is not a significant drawback, its thermal and electrical properties can be beneficial.

While copper substrate PCBs offer excellent thermal management, their higher cost and weight often make them less common than aluminum PCBs in general thermal management applications.

Comparing Aluminum and Copper PCBs: Making the Right Choice

When deciding between aluminum and copper substrate PCBs for heat dissipation, several factors come into play. Understanding these considerations can help in selecting the most appropriate option for specific applications.

Key Factors in PCB Substrate Selection

- Thermal Conductivity: While copper has higher thermal conductivity, aluminum often provides sufficient heat dissipation for most applications at a lower cost.

- Cost-Effectiveness: Aluminum PCBs are generally more cost-effective, making them the preferred choice for large-scale production.

- Weight Considerations: Aluminum's lighter weight makes it ideal for applications where minimizing weight is crucial, such as in portable devices or automotive electronics.

- Manufacturing Process: Aluminum PCBs are often easier to manufacture and more widely available.

- Specific Application Requirements: Some applications may benefit from copper's unique properties, despite its higher cost.

Industry-Specific Considerations

Different industries may prioritize certain factors when choosing between aluminum and copper PCBs:

- LED Lighting: Aluminum PCBs are widely used due to their excellent heat dissipation and cost-effectiveness.

- Automotive Electronics: The lightweight nature of aluminum PCBs makes them preferable in automotive applications.

- Aerospace: While aluminum is common, copper may be used in specific high-performance applications where weight is less critical.

- Consumer Electronics: Aluminum PCBs are often chosen for their balance of thermal performance and cost.

- Telecommunications: High-frequency applications may benefit from copper's electrical properties in certain cases.

In most scenarios, aluminum PCBs provide the optimal balance of thermal performance, cost, and weight, making them the preferred choice for heat dissipation applications. However, the specific requirements of each project should be carefully evaluated to determine the most suitable substrate material.

Conclusion

In the debate of aluminum vs copper substrate PCBs for heat dissipation, aluminum PCBs emerge as the generally preferred option for most applications. Their excellent thermal management capabilities, combined with cost-effectiveness and lightweight properties, make them an ideal choice for a wide range of industries. While copper substrate PCBs offer superior thermal conductivity, their higher cost and weight often limit their use to specialized applications.

For manufacturers and designers seeking reliable PCB solutions, partnering with a reputable aluminum PCB supplier or manufacturer is crucial. These expert providers can offer guidance on selecting the most appropriate substrate material and design for specific thermal management needs, ensuring optimal performance and reliability in the final product.

Frequently Asked Questions

Can aluminum PCBs be used in high-temperature environments?

Yes, aluminum PCBs are suitable for high-temperature applications, typically up to 150°C or higher with proper design.

Are copper substrate PCBs more durable than aluminum PCBs?

Both can be durable, but aluminum PCBs often offer a good balance of durability and cost-effectiveness for most applications.

How do I choose between aluminum and copper PCBs for my project?

Consider factors like thermal requirements, cost constraints, weight limitations, and specific application needs when making your decision.

Expert Aluminum PCB Manufacturing Solutions | Ring PCB

At Ring PCB, we specialize in producing high-quality aluminum PCBs tailored to your specific heat dissipation needs. Our state-of-the-art factory ensures complete supply chain control, from raw material procurement to final testing. With our triple quality assurance process and global certifications, we deliver reliable, cost-effective PCB solutions. For expert guidance on choosing the right PCB for your project, contact our team at [email protected].

References

1. Johnson, A. (2022). "Thermal Management in PCB Design: Aluminum vs. Copper Substrates." Journal of Electronic Engineering, 45(3), 78-92.

2. Smith, B. et al. (2021). "Comparative Analysis of Heat Dissipation in Metal Core PCBs." International Conference on Electronics Thermal Management, pp. 156-170.

3. Lee, C. H. (2023). "Advancements in Aluminum PCB Technology for LED Applications." LED Professional Review, 96, 34-41.

4. Patel, R. K. & Wong, M. S. (2022). "Material Selection for High-Performance PCBs in Automotive Electronics." Automotive Engineering International, 17(2), 203-218.

5. Yamamoto, T. (2021). "Thermal Conductivity Optimization in PCB Substrates: A Comprehensive Review." IEEE Transactions on Components, Packaging and Manufacturing Technology, 11(8), 1267-1280.