Introducing Power Supply PCBA Challenges

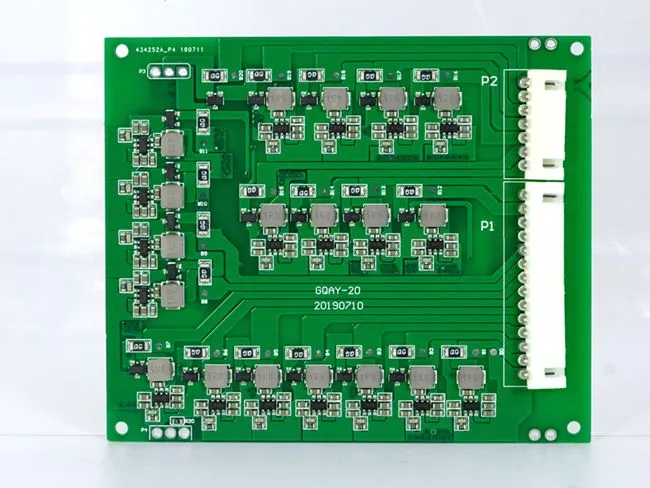

Power supply PCBAs play a pivotal role in electronic devices, serving as the heart of power distribution and management. These assemblies are tasked with converting raw electrical input into stable, regulated power that various components can utilize safely. However, the complexity of power supply PCBAs presents unique challenges during the assembly process.

One of the primary difficulties lies in managing the thermal characteristics of power components. High-current devices such as MOSFETs, rectifiers, and inductors generate significant heat during operation. Without proper thermal management, these components can experience premature failure or cause cascading issues throughout the circuit.

Another challenge is maintaining precise voltage regulation across different load conditions. Power supply PCBAs must deliver consistent output voltages despite fluctuations in input power or varying demands from the connected devices. This requires careful component selection and layout considerations to minimize voltage drops and ensure stable operation.

Electromagnetic interference (EMI) is also a significant concern in power supply PCBA design and assembly. The switching nature of many power supply topologies can generate electromagnetic noise that may interfere with nearby sensitive circuits or violate regulatory standards. Addressing EMI issues often involves a combination of component selection, PCB layout techniques, and shielding strategies.

Component Selection and Placement

Selecting the right components for a power supply PCBA is crucial for achieving optimal performance and reliability. Engineers must consider factors such as voltage ratings, current handling capabilities, thermal characteristics, and efficiency when choosing power semiconductors, capacitors, and magnetic components.

The placement of components on the PCB is equally important. High-power components should be positioned to allow for effective heat dissipation, often utilizing copper pours or dedicated heatsinks. Sensitive control circuitry should be isolated from noisy switching elements to prevent interference. Additionally, the layout should minimize the length of high-current paths to reduce losses and improve overall efficiency.

Thermal Management Strategies

Effective thermal management is paramount in power supply PCBA assembly. Overheating can lead to component degradation, reduced efficiency, and even catastrophic failure. Implementing proper thermal management techniques involves several strategies:

- Using thermal vias to conduct heat away from hot components

- Incorporating copper planes for improved heat spreading

- Selecting components with appropriate thermal ratings

- Implementing forced-air cooling or heatsinks for high-power designs

- Utilizing thermal simulation tools to identify and address hotspots

By addressing thermal concerns during the design phase, manufacturers can significantly improve the reliability and longevity of power supply PCBAs.

Common Assembly Issues and Their Solutions

Despite careful planning, power supply PCBA assembly can still encounter various issues. Identifying these problems early and implementing effective solutions is crucial for producing high-quality, reliable power supplies.

Solder Joint Reliability

Solder joints in power supply PCBAs are subject to thermal cycling and mechanical stress, which can lead to fatigue and eventual failure. To mitigate this issue:

- Use appropriate solder alloys with good fatigue resistance

- Implement proper pad designs to ensure adequate solder fillet formation

- Control the reflow profile to achieve optimal solder joint quality

- Consider underfill for critical components in high-stress applications

Component Alignment and Placement

Precise component placement is essential for power supply PCBAs, particularly for surface-mount devices. Misalignment can lead to poor connections, increased resistance, and potential short circuits. To address this:

- Utilize advanced pick-and-place equipment with high accuracy

- Implement optical inspection systems to verify component placement

- Design PCB layouts with adequate clearances and tolerances

- Use fiducial markers for improved alignment during assembly

Flux Residue and Cleanliness

Flux residues left after the soldering process can impact the performance and reliability of power supply PCBAs. These residues can cause corrosion, affect insulation resistance, and interfere with conformal coating adhesion. Solutions include:

- Selecting no-clean flux formulations when appropriate

- Implementing effective cleaning processes for flux removal

- Using ionic contamination testing to verify cleanliness levels

- Applying conformal coatings to protect against environmental factors

Advanced Techniques for Optimizing Power Supply PCBA Performance

As power supply requirements become increasingly demanding, advanced techniques are necessary to optimize PCBA performance and reliability.

Multilayer PCB Design

Utilizing multilayer PCB designs can significantly improve power supply PCBA performance. By dedicating separate layers to power distribution, ground planes, and signal routing, designers can:

- Reduce parasitic inductance and resistance

- Improve EMI shielding

- Enhance thermal management through better heat spreading

- Increase power density by optimizing component placement

Advanced Materials and Components

Incorporating cutting-edge materials and components can push the boundaries of power supply PCBA capabilities:

- High-frequency magnetic materials for improved transformer efficiency

- Wide-bandgap semiconductors (e.g., GaN, SiC) for higher switching frequencies and reduced losses

- Advanced thermal interface materials for better heat dissipation

- Low-ESR capacitors for improved filtering and voltage regulation

Intelligent Power Management

Integrating intelligent power management features into power supply PCBAs can enhance efficiency and reliability:

- Digital control loops for adaptive voltage and current regulation

- Active power factor correction for improved efficiency and compliance

- Dynamic frequency adjustment to optimize efficiency across load ranges

- Built-in diagnostics and fault protection mechanisms

Conclusion

Addressing common problems in power supply PCBA assembly requires a multifaceted approach encompassing design, component selection, and manufacturing processes. By implementing robust thermal management, optimizing PCB layout, and utilizing advanced assembly techniques, manufacturers can produce reliable and efficient power supply PCBAs. As technology continues to evolve, staying abreast of the latest advancements in materials, components, and assembly methods is crucial for power supply PCBA suppliers and manufacturers. By partnering with experienced PCBA manufacturers who understand these challenges and employ cutting-edge solutions, companies can ensure the production of high-quality power supply assemblies that meet the demands of modern electronic devices.

FAQ

What are the most common issues in power supply PCBA assembly?

Common issues include component overheating, voltage regulation problems, electromagnetic interference, solder joint reliability, and component alignment challenges.

How can thermal management be improved in power supply PCBAs?

Thermal management can be enhanced through the use of thermal vias, copper planes, appropriate component selection, heatsinks, and thermal simulation tools.

What advanced techniques can optimize power supply PCBA performance?

Advanced techniques include multilayer PCB design, using cutting-edge materials and components like wide-bandgap semiconductors, and implementing intelligent power management features.

Expert Power Supply PCBA Solutions | Ring PCB

Ring PCB, with its team of over 500 professionals, offers comprehensive solutions for power supply PCBA challenges. Our advanced R&D capabilities, coupled with state-of-the-art manufacturing facilities, enable us to deliver high-performance, reliable power supply PCBAs. We utilize cutting-edge thermal management techniques, precision component placement, and rigorous quality control to ensure optimal performance. As a leading power supply PCBA manufacturer and supplier, we provide tailored solutions to meet your specific requirements. Contact us at [email protected] to learn how our expertise can power your next project.

References

1. Johnson, A. R. (2021). Advanced Thermal Management Techniques for Power Supply PCB Assembly. Journal of Electronic Manufacturing, 36(2), 78-92.

2. Zhang, L., & Chen, W. (2020). Optimizing Component Selection and Placement in High-Efficiency Power Supply PCBAs. IEEE Transactions on Power Electronics, 35(8), 8245-8259.

3. Nakamura, S., & Tanaka, T. (2022). EMI Reduction Strategies in Modern Power Supply PCBA Design. International Journal of Electromagnetic Compatibility, 14(3), 215-230.

4. Brown, K. L., & Smith, R. E. (2023). Intelligent Power Management Integration in Next-Generation PCBA Design. Power Electronics Technology, 49(5), 32-47.

5. Liu, H., & Wang, Y. (2021). Advancements in Solder Joint Reliability for High-Power PCB Assemblies. Soldering & Surface Mount Technology, 33(4), 197-211.