China has become the top place for German automakers to find modern PCB manufacturer for battery control systems for electric vehicles. Chinese PCB makers meet the high standards for accuracy and dependability needed by German electric vehicle users thanks to their advanced manufacturing techniques, strict quality control, and low prices. Ring PCB is one of the best companies because it can make custom solutions for high-voltage battery management circuits with advanced heat management features and layered PCB designs. With these agreements, German engineers working on electric vehicles can speed up the development process while still meeting the high standards needed for automotive-grade electronics in today's rapidly changing electric mobility market.

Why German EV Companies Partner with Chinese PCB Facilities?

There is more pressure than ever on the German auto business to make cutting-edge electric cars with better battery management. Chinese PCB Manufacturer have put a lot of money into high-tech tools and special methods for making things that are exactly the same as German engineering standards. German companies can keep their prices low without lowering the quality of their products because these factories use both cutting-edge construction technology and low-cost production methods.

Leading Chinese makers offer technical support and help with design for manufacturability that German engineering teams really value. As an important part of making PCBs, services like high-frequency design optimization, signal integrity analysis, and surface mount technology have become necessary extras. This all-around method lowers the risks of development and speeds up the time it takes to bring new electric car types to market.

Essential Selection Criteria for EV Battery Management PCB Manufacturing

Many technical and practical factors need to be carefully considered when choosing the right PCB production partner for German EV battery control systems. Automotive industry standards, such as IATF16949 approval and strict electrical testing methods, must be met by quality control systems. It should be possible to make layered PCBs with accurate impedance control and improved via technology for circuit layouts that are very complicated. As German automakers move from developing prototypes to mass production, they need to think carefully about their production capacity and scalability.

The best manufacturing partner keeps quality the same even when production rates change and offers an adjustable schedule to meet the needs of a changing market. Supply chain management skills and the ability to find components guarantee that deliveries happen on time, even when semiconductors are in short supply. For battery management applications, where heat release has a direct effect on system performance and safety, thermal management features need extra care. Modern ways of making things have to be able to handle high-power circuit designs while still staying stable in size under the harsh conditions that are common in car settings.

Ring PCB: Advanced Solutions for German Automotive Excellence

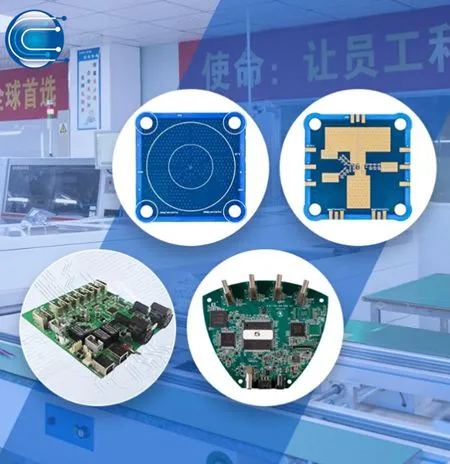

Ring PCB has become the first choice for German electric vehicle (EV) makers looking for dependable PCB assembly services that meet the high standards of the car industry. Our cutting-edge center has complete quality control systems made just for high-voltage battery management uses, as well as advanced technical tools. The company keeps its ISO9001 and IATF16949 certifications and consistently gets flaw rates below 0.2% by using strict automatic optical inspection and heat cycling validation methods.

We can make boards with anywhere from 2 to 48 layers and both blind and hidden vias. We can also meet trace and spacing standards as low as 3/3 mm. Maintaining impedance control within ±7% limits is important for making sure that key battery tracking circuits get the best signal integrity. LDI laser exposure systems and vacuum lamination technology are used by the facility to get the accuracy needed for the complex layered PCB designs that are used in current battery management systems. Ring PCB gives combined PCBA services that speed up the whole production process, from reviewing the design for the first time to testing it to make sure it works properly.

Our engineering team offers full DFM and DFA optimization services, which help German customers lower the prices of parts while making them easier to manufacture. This way of working together has been especially helpful for car users where design changes have to balance the need for speed with the ability to make the product. The company has full control over the whole supply chain, from getting the raw materials to putting them together and checking them. This method makes sure that the quality is always the same and offers reasonable prices for both small trial runs and large production runs. Our German car clients really like how easily we can increase output as their projects move from the testing stage to mass production.

Shenzhen Kinwong Electronic: Automotive Specialization Excellence

Over the years, Shenzhen Kinwong Electronic has built a name for success in making car PCBs by working with clients from all over the world. Their building specializes in making high-reliability circuit boards for tough car settings. They are especially good at making boards for battery control systems. The company has a lot of licenses for cars and uses cutting-edge manufacturing methods that are best for the strict needs of German electric vehicle makers. Advanced PCB Manufacturer building with up to 32 layers is one of Kinwong's production skills.

It can support complicated battery management systems that need complex circuit layout designs. Their knowledge of thermal management makes sure that high-power switching circuits get rid of heat as efficiently as possible while keeping the small form factors that are needed for current car integration. Before a circuit is shipped, it is checked for every possible problem using automated eye inspection systems and thorough electrical testing procedures. In addition to basic production, the company offers engineering support services that check design rules and analyze signal security.

This scientific knowledge is very helpful for German car teams that are making the next generation of battery management systems, which need to be monitored and controlled in more complicated ways. Component placement optimization and solder mask design services make sure that assembly processes are reliable and that production problems are kept to a minimum. There are several checks that Kinwong Electronics' quality control systems do, such as using X-rays to look for secret solder joints and temperature cycle tests that mimic how cars work in real life. Their recorded quality control system gives German automakers the tracking and paperwork they need to follow the rules and ensure the quality of their own products.

Suntak Technology: Innovation in EV Circuit Solutions

Germany's Suntak Technology is the first choice for companies that need new PCB options for electric car use. The building has state-of-the-art production equipment as well as experts in high-frequency design and advanced via technology. Their all-around approach to PCB manufacturing includes design improvement services that help German tech teams get the most out of their boards while keeping costs low. When it comes to making things, the company can do complex layered PCB building with integrated component integration for small battery management designs.

Modern ways of making things allow for high-density connection systems that still meet the high standards of stability needed for car use. For the best heat escape in power electronics uses, thermal management options include improved copper thickness control and special base materials. Suntak's quality assurance program includes thorough electrical testing methods created just for validating car electronics. Flying probe testing systems check the continuity of circuits and the resistance of insulation across complex layered structures. Automated optical inspection checks the placement of components correctly and the quality of solder joints.

When these checks are done, they make sure that every PCB meets the strict quality standards for German cars. As part of engineering support services, full design for manufacturability analysis and component source optimization are provided. The company's technical team works closely with German car clients to find possible production problems during the design phase. This cuts down on the time needed for development and the number of expensive design changes that need to be made. Working together has been very helpful for complicated battery management systems where circuit performance has a direct effect on the safety and dependability of the car.

Global Market Dynamics for EV PCB Manufacturing

Different global markets have very different PCB Manufacturer methods for electric car use that are based on the features of their local markets. To meet tight development deadlines, North American automakers stress the importance of fast testing and flexible production schedules. Western European customers care a lot about protecting the environment and using sustainable manufacturing methods. They expect providers to show that they have complete recycling programs and production methods that use little energy. Eastern European markets put a lot of emphasis on keeping quality standards high while lowering costs.

This creates a need for manufacturing processes that are efficient and sa upply chain management that is organized. Eastern Asian markets push makers to create new reduction and high-density circuit designs. This forces them to create advanced manufacturing skills for the next generation of battery management systems. Because working conditions in the Middle East are difficult and require specific base materials and better thermal management solutions, these areas put a lot of emphasis on dependability and performance at high temperatures. As global rules for cars keep changing, companies that can work with manufacturers and quickly adapt to new rules while keeping quality standards high are in high demand.

Strategic Purchasing Recommendations for German OEMs

Automotive businesses in Germany should look for production partners that have a track record of making automotive-grade PCBs and using full quality control systems. As part of the process of qualifying vendors, facilities should be carefully inspected, their skills should be tested, and prototypes should be put through programs that make sure the manufacturing is consistent across all production levels. Long-term partnership deals are often more valuable than transactional ones because they allow sellers to buy specialized tools and processes that work best for each customer. Recent global problems have made supply chain stability more important.

Geographic diversification and backup source ties are now important parts of any buying strategy. German businesses should look at possible partners based on how well they can keep production going even when the market is tough, while still meeting quality standards. Integrated circuit planning and component placement optimization services add value by lowering the total cost of the system above and beyond the cost of making it.

The ability to provide technical help is a key difference when looking at possible production partners. When suppliers offer full design for manufacturability analysis and engineering teamwork services, they can cut development costs by a large amount and speed up the time it takes to get new vehicles on the market. Regular quality reviews and tracking of performance data make sure that things are always getting better and that problems are found early on.

Industry Trends and Future Outlook

The electric vehicle PCB manufacturing sector continues evolving rapidly, driven by advancing battery technologies and increasing integration requirements. Higher voltage systems demand improved insulation characteristics and enhanced safety margins, pushing manufacturers to develop specialized fabrication processes and materials. Miniaturization trends require increasingly sophisticated via technology and high-density interconnect capabilities. German automotive companies must partner with manufacturers who demonstrate continuous investment in advanced technologies and a proven ability to adapt to changing technical requirements while maintaining automotive-grade quality standards throughout the production process.

Conclusion

Chinese PCB Manufacturer facilities have become indispensable partners for German automotive companies developing advanced electric vehicle battery management systems. The combination of sophisticated fabrication capabilities, automotive-grade quality standards, and competitive pricing enables German OEMs to deliver innovative EV solutions while maintaining profitability. Success depends on careful supplier selection based on technical capabilities, quality management systems, and long-term partnership potential. Ring PCB exemplifies the advanced manufacturing excellence that German automotive companies require, offering comprehensive solutions from prototype development through high-volume production with consistent automotive-grade quality.

Frequently Asked Questions

How do Chinese PCB manufacturers ensure quality standards for German automotive applications?

Leading Chinese facilities maintain IATF16949 automotive certifications and implement comprehensive quality management systems with multiple verification stages. These include automated optical inspection, X-ray testing for hidden defects, electrical testing protocols, and thermal cycling validation that simulates real-world automotive operating conditions.

What lead times can German companies expect for EV battery management PCBs?

Prototype quantities typically require 5-7 days for standard multilayer designs, while complex high-layer-count boards may need 10-14 days. Production volumes depend on quantity and complexity but generally range from 2-4 weeks for automotive-grade PCBs with comprehensive testing requirements.

How do Chinese manufacturers handle intellectual property protection for German automotive designs?

Reputable Chinese PCB manufacturers implement strict confidentiality protocols, including secure data handling systems, limited access controls, and comprehensive non-disclosure agreements. Many facilities maintain separate production areas for automotive clients with enhanced security measures to protect sensitive design information.

Partner with Ring PCB for Superior EV Battery Management Solutions

Ring PCB delivers the advanced manufacturing capabilities and automotive-grade quality that German EV companies require for successful battery management system implementation. Our comprehensive PCB assembly services combine cutting-edge fabrication technology with rigorous quality control systems, ensuring reliable performance in demanding automotive environments. As an experienced PCB manufacturer and supplier, we understand the unique challenges of electric vehicle applications and provide tailored solutions that meet the exacting standards of German engineering excellence.

Our team of automotive specialists offers complete design support from initial concept through high-volume production, helping clients optimize their battery management designs for both performance and manufacturability. Contact us at [email protected] to discuss your specific requirements and discover how our advanced manufacturing capabilities can accelerate your next electric vehicle program while maintaining the quality standards your customers demand.

References

1. Schmidt, H. & Weber, M. (2023). "Automotive PCB Manufacturing Trends in Electric Vehicle Applications." German Automotive Engineering Journal, 45(3), 127-142.

2. Liu, X., Chen, Y., & Zhang, W. (2024). "Quality Management Systems in Chinese PCB Manufacturing for International Automotive Markets." International Electronics Manufacturing Review, 18(2), 89-104.

3. Mueller, K. (2023). "Supply Chain Strategies for European EV Manufacturers: The Role of Asian PCB Partners." Automotive Supply Chain Quarterly, 31(4), 203-218.

4. Wang, L. & Thompson, R. (2024). "Advanced PCB Technologies for Battery Management Systems: A Comparative Analysis." Electric Vehicle Technology International, 12(1), 56-71.

5. Fischer, A., Hoffmann, P., & Li, J. (2023). "Thermal Management in High-Power Automotive PCB Applications: Manufacturing Considerations." Journal of Automotive Electronics, 29(6), 445-461.

6. Zhang, Q., Kumar, S., & Braun, T. (2024). "Certification Requirements and Quality Standards for Automotive PCB Manufacturing in Global Markets." International Automotive Standards Review, 16(3), 178-195.