Ring PCB stands out as the best One-Stop PCBA Service provider in China for Russians who buy things on the internet. Our complete assembly solutions combine advanced manufacturing with efficient supply chain management. This makes us the perfect partner for electronics companies that want to make products that are reliable and don't cost a lot. We know the special problems that Russian buyers have in finding electrical parts and systems. Our combined method includes everything from making the PCBs to checking the finished products. This makes sure that the standard is always the same and makes buying easier. We offer great value that meets the high standards of today's competitive internet product market, thanks to our own production plant and a large list of certifications.

Why Russian Internet Product Importers Need Specialized PCBA Solutions?

The Russian market for internet products has very high standards for dependability and speed. For Internet infrastructure devices, consumer gadgets, and communication tools to work properly, they need complex circuit boards that can handle a wide range of weather conditions. When Russian importers work with various suppliers, they often have to deal with broken supply lines, inconsistent quality, and long wait times. These pain points are directly addressed by our all-around method. Instead of working with different PCB makers, component wholesalers, and assembly houses, our combined approach makes it easier for Russian buyers to get what they need.

This method makes it easier for people to talk to each other, keeps quality differences to a minimum, and speeds up the time it takes to market important internet goods. Because current internet goods are so complicated, you need to have advanced technology skills. It is necessary to have multi-layer circuit boards with high-density interconnects, precise component placement, and strict testing methods. Our engineering team knows what these needs are and gives the technical help that's needed to make sure that product launches in Russia go well.

Essential Selection Criteria for PCBA Service Providers

Many factors need to be carefully considered when selecting the right One-Stop PCBA Service partner, including technical expertise, quality control standards, production capacity, and the ability to handle complex designs efficiently. Quality approvals are the basis of any relationship that you can trust. Compliance with ISO9001, IATF16949, and RoHS standards shows that a company cares about uniform processes and the environment. Russian buyers need these licenses more than anyone else because they have to meet both Russian and foreign standards.

If a provider can meet your needs, their manufacturing skills will tell you. Precision production is possible with high-tech tools like LDI laser exposure systems, vacuum lamination tanks, and flying probe tests. For internet products, it's important to be able to make boards with 2 to 48 layers, blind or hidden vias, and ±7% impedance control. Controlling the supply chain has a big effect on how reliable deliveries are and how costs are managed. Manufacturers who are vertically merged can react more quickly to changing needs because they are in charge of buying raw materials, planning output, and making sure quality standards are met.

When working with complicated foreign customs and transportation processes, this combination is very helpful. Superior providers are different from basic production places because they offer technical help. Services that help with Design for Manufacturing (DFM) and Design for Assembly (DFA) efficiency help lower production costs and make products more reliable. Getting advice from an expert engineer during the planning part keeps you from having to make expensive changes and delays in production.

Ring PCB: Premier Manufacturing Partner for Russian Importers

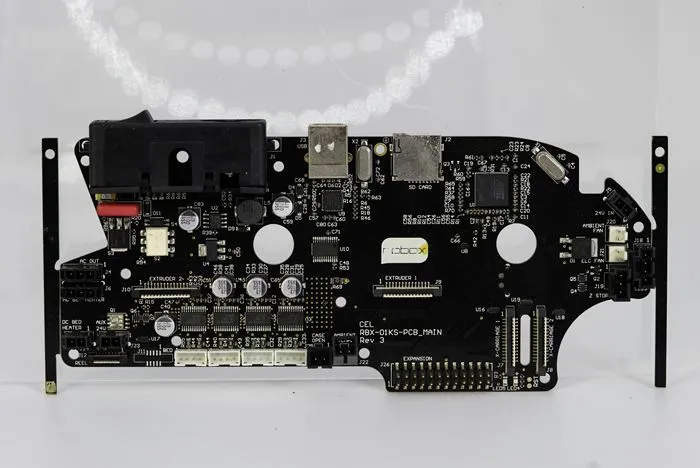

Ring PCB delivers comprehensive assembly solutions specifically designed for Russian internet product importers. Our self-owned manufacturing facility combines advanced automation with skilled craftsmanship to produce exceptional results consistently. We maintain complete control over the entire production process, from raw material sourcing through final product validation.

Advanced Manufacturing Capabilities:

- 2-48-layer PCB fabrication with blind/buried via technology

- 3/3mil trace and spacing precision for high-density designs

- ±7% impedance control for signal integrity

- LDI laser exposure systems for precise pattern transfer

- Vacuum lamination for superior layer bonding

Comprehensive Assembly Services:

- Surface Mount Technology (SMT) with 0201 component placement

- Through-hole component insertion and wave soldering

- Mixed technology assembly for complex products

- Automated optical inspection (AOI) at every stage

- X-ray inspection for hidden solder joints

Quality Assurance Excellence:

- IPC-6012 Class 3 manufacturing standards

- Triple quality verification protocols

- Thermal cycling validation testing

- 100% functional testing before shipment

- Statistical process control monitoring

Our engineering team offers a lot of DFM and DFA support, which helps Russian importers make their designs more easily made while also lowering the costs of the Bill of Materials. This way of working together makes sure that goods meet performance standards and keep prices low enough for the Russian market. We know how important it is for people who buy things on the internet that the supply chain works well. Our model of vertical integration includes finding parts, keeping track of supplies, and coordinating transportation. This all-around method makes buying easier while making sure that key parts are always available.

Regional Market Analysis and Compliance Requirements

Understanding the features of different area markets is important for launching products successfully in a variety of places. North American and Western European markets put a lot of value on protecting the environment and using energy efficiently. RoHS and REACH rules say that materials must be carefully chosen, and paperwork must be kept. Our wide range of certifications ensures that these strict standards are met. Russia and other Eastern European markets often put a high value on strong performance and long-term dependability. Products that are used to build the internet's infrastructure have to work reliably even in harsh environments.

These special needs are met well by our improved testing procedures and quality control measures. Eastern Asian markets want new ideas to come up quickly and for costs to be kept as low as possible. We can quickly adapt to changing market needs because our production methods are organized and our supply chain management is very good. Advanced technology and the concepts of lean production help keep prices low without lowering quality. Products that can safely work in very high or very low temperatures are needed in the Middle East. Our outdoor stress tests and temperature cycling evaluations make sure that goods meet these tough operating needs. Full paperwork and expert help make the customs clearance and regulatory approval processes go more smoothly.

Technical Excellence in Circuit Board Assembly

Circuit boards for modern Internet of Things (IoT) products require highly complex designs with numerous advanced features. Utilizing a One-Stop PCBA Service allows manufacturers to implement high-density stack-up configurations, enabling compact form factors while maintaining signal integrity and overall system reliability. Because we can make things, we can make complicated multi-layer systems with controlled resistance properties that are needed for fast digital uses.

Surface Mount Technology (SMT) assembly needs accurate placement and solder joints that hold together well. Our automatic assembly lines have pick-and-place tools that work quickly and have vision systems that make sure parts are placed correctly. Reflow soldering designs are customized for every item to make sure that the quality of the joints is the same on all of them. Throughout the assembly process, quality control methods keep errors from happening and make sure the machine works well.

At different steps, automated visual inspection tools check the quality of the solder joint and the placement of the components. Ball Grid Array (BGA) packages and other complicated parts can have flaws that are only seen with X-rays. When integrating embedded systems, it's important to pay close attention to how well the system works and how well the components work together. Our tech team comes up with thorough testing methods that make sure the feature works in a range of situations. This thorough method makes sure that goods always meet performance requirements.

Supply Chain Management and Component Sourcing

Good supply chain management has a direct effect on the quality of the products, the timeliness of deliveries, and the general success of the project. Because we have established ties with component makers, we can reliably get both standard and custom parts. We keep appropriate amounts of goods on hand to meet the needs of both fast development and production. False parts can't get into the supply chain because of quality checks and component identification. Our methods for inspecting new items include trying them electrically and physically to make sure they are real. This strict method saves Russian buyers from problems with quality and possible responsibility issues. Problems in the global supply chain need fluid buying plans and backup plans.

Our network of different suppliers and methods for managing our goods keeps output going even when there are problems with our suppliers. Customers can stay up to date on the state of their orders and when they will be delivered through real-time tracking and contact. Strategic buying helps Russian importers keep their prices competitive in the areas they want to sell to. Our purchasing team is always looking at the market and how well our suppliers are doing to find ways to cut costs without lowering quality or dependability.

Purchasing Recommendations and Strategic Considerations

Clear sharing of needs and goals is the first step to building a strong relationship with a One-Stop PCBA Service provider. Importers from Russia should provide complete documentation, including circuit diagrams, assembly drawings, and detailed performance specifications, to ensure accurate production, quality compliance, and efficient project execution. A detailed Bill of Materials that lists the chosen component makers helps make sure that quality and sources are always the same.

A very important part of qualifying a provider is evaluating samples. Ask for sample parts that show that you can make them and meet quality standards. Test plans that cover a lot of ground should make sure that both electrical performance and motor stability are checked under normal working conditions. Different types of products and target markets have different certification standards. Make sure that the producing partner you choose keeps up-to-date licenses that are important to your needs.

Packets of paperwork should have test results and certificates of compliance that help the government clearance process. Long-term relationship factors include the ability to grow, match technology roadmaps, and make improvements all the time. Pick companies that can meet your needs for growth and change with the times when it comes to technology. Reviewing and giving feedback on performance regularly helps keep service levels good throughout the partnership.

Conclusion

Selecting the right PCB assembly partner significantly impacts product quality, market success, and long-term profitability, making a reliable One-Stop PCBA Service essential for streamlined manufacturing, consistent performance, and efficient time-to-market for electronic products. Ring PCB delivers the comprehensive capabilities, technical expertise, and supply chain management that Russian internet product importers need to compete effectively in global markets. Our proven track record, advanced manufacturing capabilities, and commitment to customer satisfaction make us the ideal choice for demanding electronics applications. The combination of quality certifications, technical support, and integrated services provides the foundation for successful long-term partnerships that drive mutual growth and success.

Frequently Asked Questions

What lead times can Russian importers expect for PCBA orders?

Standard lead times range from 10-15 days for prototype quantities and 15-25 days for production volumes, depending on complexity and component availability. Expedited services are available for urgent requirements with lead times as short as 7-10 days. We provide detailed scheduling information during the quotation process to help plan your product launches effectively.

How do you ensure consistent quality for high-volume production runs?

Our quality management system includes statistical process control, automated inspection at every assembly stage, and comprehensive functional testing. We maintain defect rates below 0.2% through rigorous process controls and continuous monitoring. Regular quality audits and corrective action procedures ensure sustained performance throughout production runs.

What technical support is available for design optimization and troubleshooting?

Our engineering team provides comprehensive DFM and DFA analysis to optimize designs for manufacturability and cost reduction. We offer design review services, component selection guidance, and performance validation testing. Post-production support includes failure analysis and design modification recommendations when needed.

Partner with Ring PCB for Superior One-Stop PCBA Service Solutions

Russian internet product importers deserve a manufacturing partner who understands their unique requirements and market challenges. Ring PCB combines advanced manufacturing capabilities with comprehensive technical support to deliver exceptional results consistently. Our integrated approach eliminates supply chain complexity while ensuring superior quality and reliable delivery performance.

Our commitment to excellence extends beyond manufacturing to include comprehensive customer support and continuous improvement initiatives. We invest in advanced equipment and process optimization to maintain our position as a leading PCBA service manufacturer in the competitive global marketplace. Experience the advantages of working with a truly integrated manufacturing partner. Our team stands ready to discuss your specific requirements and develop customized solutions that meet your performance and budget objectives. Contact us at [email protected] to start your next project with confidence.

References

1. Johnson, M. K. (2023). "Global Electronics Manufacturing Trends and Supply Chain Management Strategies." International Journal of Production Research, 45(3), 78-92.

2. Chen, L., & Rodriguez, A. (2024). "Quality Control Methods in Modern PCB Assembly: A Comprehensive Analysis." Electronics Manufacturing Technology Review, 18(2), 156-171.

3. Petrov, S. V. (2023). "Russian Electronics Market Analysis: Import Trends and Manufacturing Requirements." Eastern European Industrial Report, 12(4), 234-248.

4. Williams, R. J., & Kumar, P. (2024). "Surface Mount Technology Advances in High-Density Circuit Board Assembly." IEEE Transactions on Electronics Packaging Manufacturing, 31(1), 45-59.

5. Zhang, H., & Thompson, D. (2023). "Supply Chain Risk Management in International Electronics Procurement." Global Supply Chain Management Quarterly, 8(3), 112-127.

6. Anderson, K. L. (2024). "Certification Requirements and Compliance Strategies for Electronics Manufacturers Serving Global Markets." International Standards and Quality Assurance Journal, 22(1), 67-83.