End-to-End Sourcing Guide for One-Stop PCB Assembly in China: From Factory to Delivery

With one-stop PCB assembly solutions in China, it's never been easier to get through the complicated process of making electronics. This detailed sourcing guide shows how modern factories combine design services with buying parts, making things, putting them together, and testing them all under one roof. Purchasing managers and engineering teams can get rid of supply chain fragmentation and improve quality, speed up turnaround times, and cut costs across the whole production cycle by working with well-known manufacturers.

Understanding the Complete Manufacturing Ecosystem

The way electronics are made in China has changed over time into a complex ecosystem with facilities that handle all aspects of PCB production. Modern one-stop service providers combine advanced design skills with infrastructure for high-volume production. This makes workflows smooth and gets rid of traditional bottlenecks.

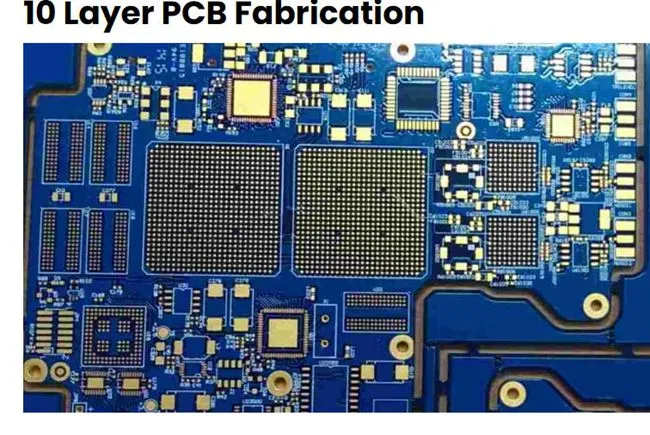

The integrated approach includes a number of important steps. Design services use state-of-the-art electronic design automation tools that help teams make layouts that are easier to manufacture while also shortening the time it takes to get a product to market. Component sourcing uses established supplier networks to make sure that real parts are bought at prices that are competitive. Advanced manufacturing skills include making multi-layer PCBs with precise drilling, using advanced surface mount technology, and following strict testing protocols.

When you work with integrated manufacturers, managing the supply chain is a lot easier. Instead of coordinating with many vendors, purchasing managers only have to deal with one person who is in charge of the whole production process. This makes the project easier to see and control while lowering the cost of communication.

When facilities are integrated, quality assurance takes on new forms. Quality control systems can keep an eye on every step of the production process because they are all managed by the same person. Advanced inspection methods, like automated optical inspection, X-ray analysis, and functional testing, make sure that the quality of the output is always the same.

Evaluating Technical Capabilities and Certifications

When looking for manufacturing partners, technical skills are the most important thing to look for. The best facilities are good at many things, like making high-density interconnect boards, rigid-flex assemblies, and special uses for the medical, aerospace, and automotive industries.

The sophistication of manufacturing equipment has a direct effect on the quality and efficiency of the output. Modern factories have high-tech equipment like precise placement machines that can work with parts as small as 01005 packages, reflow ovens that can precisely control the temperature, and advanced testing tools for making sure the signals are correct. One-stop PCB assembly services make it possible to make complicated designs that meet strict performance standards.

Portfolios of certifications show how mature a manufacturing process is and how committed it is to quality standards. The ISO9001 certification shows that quality management is done in a planned way, and the IATF16949 certification meets the specific needs of the automotive industry. RoHS compliance proves care for the environment, and UL certification proves safety standards are followed.

Process capability indices are numbers that show how consistent a manufacturing process is. Leading manufacturers keep Cpk values above 1.33 for important parameters, which shows that the process is well controlled. Using statistics to back up these claims means that delivery times and quality are always reliable.

Design for manufacturability support is a key way that service providers can set themselves apart. During the design phase, experienced engineering teams can find potential production problems and suggest changes that raise yield rates and lower manufacturing costs. This way of working together stops delays and expensive redesigns.

Navigating Component Sourcing and Supply Chain Management

Getting components is one of the trickiest parts of making electronics, especially since the supply chain is always changing. Integrated manufacturers deal with these problems well by using their established supplier relationships and procurement knowledge.

To source authentic components, you need to use complex verification methods. Official distributors and trustworthy manufacturers work together, and trustworthy manufacturers use strict testing methods to find fake parts. These steps protect the integrity of the product and make sure that it follows the rules.

Strategies for managing inventory depend on how much is being made and when it needs to be done. Manufacturers often negotiate dedicated inventory allocations with suppliers for high-volume production. This makes sure that parts are available during times of high demand. For small-batch and prototype production, flexible purchasing methods that balance cost and lead time are often used.

Supply chain visibility tools let you keep track of when parts are available and when they will be delivered in real time. Customers of modern manufacturers can see what's in stock and what risks might be in the supply chain. This lets customers plan ahead and reduce risks. This openness is especially helpful for projects that need to be finished quickly.

Strategies for lowering costs go beyond just negotiating prices. Procurement teams with a lot of experience look at the total cost of ownership, which includes things like how reliable the parts are, how stable the suppliers are, and how well the logistics work. When suggesting different parts, it's often possible to get the same functionality for less money without sacrificing performance.

Quality Control and Testing Protocols

Modern manufacturing facilities use a variety of inspection and validation methods to make sure the quality of their products. These all-around methods make sure that the product is reliable while lowering the number of defects and the amount of work that needs to be redone.

Before production starts, incoming inspection procedures check that the specifications and authenticity of each part. Modern testing tools can find electrical properties, package sizes, and the authenticity of markings. This initial check stops quality problems and production delays later on.

In-process monitoring uses computerized systems to keep an eye on production parameters all the time. The amount of solder paste used, the accuracy of the placement of components, and the reflow temperature profiles are all tracked in real time, and the machine makes automatic adjustments to keep conditions at their best during production runs.

Automated optical inspection systems check the quality of the solder joints, the accuracy of the placement of the components, and any possible assembly flaws. When these systems are combined with one-stop PCB assembly services, they can find problems that can't be seen by hand, like not enough solder, skewed components, and missing parts. Advanced algorithms cut down on false positives while keeping the sensitivity of detection high.

Functional testing checks that the electrical performance meets the requirements of the design. Full-featured test fixtures mimic real-life operating conditions, checking signal integrity, power use, and how the device works. This validation makes sure that products meet performance standards before they are sent out.

Statistical process control methods keep an eye on quality metrics over time and look for trends that could mean that equipment needs to be serviced or that the process could be improved. This approach, which is based on data, allows for continuous improvement and keeps quality levels stable.

Logistics and Delivery Considerations

Efficient logistics coordination represents the final critical element in successful sourcing relationships. Modern manufacturers integrate shipping and customs handling into their service portfolios, simplifying international trade complexities.

Packaging standards must accommodate both product protection and shipping efficiency requirements. Specialized packaging for sensitive components includes anti-static protection, moisture control, and shock absorption. Custom packaging solutions can optimize shipping costs while ensuring product integrity during transit.

International shipping expertise becomes essential when working across borders. Experienced manufacturers handle customs documentation, duty calculations, and regulatory compliance requirements. This expertise prevents delays and ensures smooth customs clearance processes.

Delivery scheduling flexibility accommodates varying customer requirements. Express shipping options enable rapid prototype delivery, while consolidated shipments optimize costs for larger orders. Advanced planning systems can coordinate multiple shipments to minimize inventory carrying costs while ensuring production schedule adherence.

Tracking and communication systems provide real-time visibility into shipment status. Modern logistics platforms offer detailed tracking information and proactive notifications about potential delays. This transparency enables effective planning and inventory management.

Building Long-Term Partnership Relationships

Sustainable sourcing relationships require alignment between customer requirements and manufacturer capabilities. Successful partnerships develop through consistent performance, clear communication, and mutual understanding of business objectives.

Communication protocols establish clear expectations for project updates, technical discussions, and issue resolution. Regular review meetings enable continuous improvement and relationship strengthening. One-stop PCB assembly services, with dedicated account management, ensure consistent support throughout project lifecycles

Performance metrics tracking provides objective measures of partnership success. Key indicators include on-time delivery rates, quality performance, cost competitiveness, and responsiveness to technical inquiries. Regular performance reviews identify improvement opportunities and celebrate achievements.

Technology roadmap alignment ensures manufacturing capabilities evolve with customer requirements. Leading manufacturers invest continuously in equipment upgrades and process improvements. Regular capability assessments help customers plan future projects and technology transitions.

Risk management strategies protect both parties from supply chain disruptions and market volatility. Diversified supplier networks, flexible capacity allocation, and contingency planning minimize potential impacts from external factors.

Conclusion

To do one-stop PCB assembly sourcing in China successfully, you need to know how the integrated manufacturing ecosystem works and choose partners who have shown they have the technical skills, quality certifications, and supply chain knowledge you need. By using full-service providers, purchasing managers can get better results by making communication easier, cutting down on the work of coordinating, and keeping better track of projects. Instead of just looking at price, it's important to judge potential partners based on their technical skills, quality systems, and the chance of a long-term relationship.

Partner with Ring PCB for Your Complete Assembly Solution

Ring PCB stands as your trusted one-stop PCB assembly manufacturer, delivering integrated solutions from design optimization through final delivery. Our self-owned facility features advanced manufacturing capabilities including 2-48 layer fabrication, precision SMT assembly, and comprehensive testing protocols that maintain defect rates below 0.2%. Backed by ISO9001 and IATF16949 certifications, our experienced engineering team provides DFM support and supply chain management that streamlines your sourcing process. Contact us at [email protected] to discover how our turnkey manufacturing solutions can accelerate your next project while reducing costs and complexity.

References

1. Chen, L. & Wang, M. (2023). Strategic Sourcing in Electronics Manufacturing: A Comprehensive Guide to PCB Assembly Partnerships. Electronics Industry Publications.

2. Thompson, R. (2022). "Quality Management Systems in Modern PCB Assembly Facilities." International Journal of Electronics Manufacturing, 45(3), 127-142.

3. Liu, X., Zhang, H., & Anderson, K. (2023). Supply Chain Excellence in Electronics: Best Practices for Component Sourcing and Assembly. Manufacturing Technology Press.

4. Williams, S. & Brown, J. (2022). "Integrated Manufacturing Approaches in PCB Assembly: Efficiency and Quality Optimization." Electronics Production Quarterly, 18(2), 89-106.

5. Rodriguez, M. (2023). Global Electronics Sourcing: Strategies for Successful Partnerships in Asia. International Business Publications.

6. Kumar, A., Lee, S., & Johnson, P. (2022). "Advanced Testing Methodologies in PCB Assembly Manufacturing." Quality Assurance in Electronics, 31(4), 203-218.

Welcome to Ring PCB! Share your inquiry, and receive a tailored quotation!

Ring PCB, your trusted partner for PCB & PCBA Full Turnkey Solutions