French companies mostly get their high-layer multilayer PCBs from China's three main manufacturing hubs: Shenzhen for fast prototyping and new ideas, Dongguan-Huizhou for cheap mass production, and Shanghai for advanced materials processing. These areas work together to provide full multilayer PCB solutions with sophisticated stack-up configurations and layers ranging from 2 to 48. They serve the aerospace, telecommunications, automotive electronics, and industrial automation industries through well-established supply chains that are tailored to European buying needs.

Comprehending High-Layer Multilayer PCBs in Industrial Applications

What Are High-Layer Multilayer PCBs?

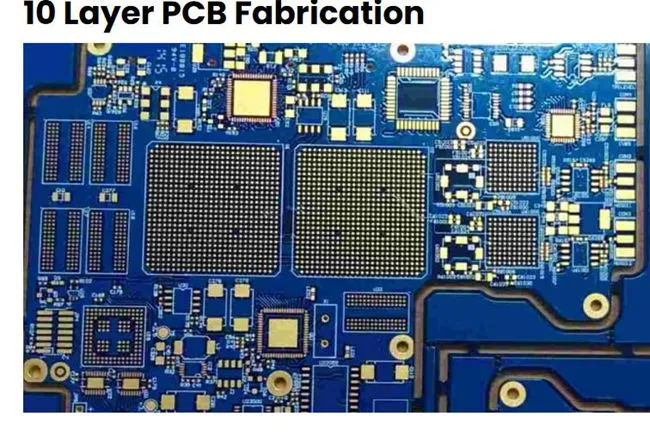

There are usually between 8 and 48 high-layer multilayer PCBs, which are complex circuit boards with many conductive layers split by insulating materials. To get the most routing density, these complicated assemblies use advanced stack-up topologies that include microvias, blind vias, and buried vias. Copper foil layers are sandwiched between dielectric materials like FR4, polyimide, and special Rogers laminates during the building process.

To make something, it has to be precisely laminated at controlled temperatures and pressures, and then it has to be drilled, plated, and etched. Each layer has a specific job to do, like sending signals, distributing power, and acting as a ground plane. This lets engineers fit more features into smaller packages.

Advantages of Using High-Layer Multilayer PCBs in Industrial Settings

High-layer designs are especially useful for industrial uses that need high levels of reliability and performance. Better thermal management spreads heat more evenly across multiple layers, which keeps parts from getting too hot in tough conditions. Dedicated ground planes and controlled impedance routing improve signal integrity, which is very important for high-frequency uses.

Engineers can fit complex circuits into smaller enclosures because they take up less space. This is very important for current industrial equipment where size is very important. By strategically placing layers and using filtering methods, the multilayer approach lowers electromagnetic interference. This makes sure that stable operation can happen in electrically noisy industrial settings.

Typical Applications Among French Industrial Firms

High-layer boards are used a lot by French aerospace companies in avionics systems, flying controls, and satellite communications equipment that has to be reliable. These PCBs are used by companies that make industrial automation equipment like programmable logic controllers, servo drives, and human-machine interfaces that need to be accurate and respond quickly.

Multilayer designs are needed for 5G base stations, fiber optic networking gear, and data center hardware as part of telecommunications infrastructure projects. These boards are used by defense contractors in radar systems, electronic warfare gear, and secure communication devices that need to work reliably in harsh circumstances.

Key Locations and Clusters for High-Layer Multilayer PCB Manufacturing in China

Major Manufacturing Hubs in China for Multilayer PCBs

With more than 300 sites specializing in rapid prototyping and small-batch production, Shenzhen is known as China's innovation capital for

PCB manufacturing. Because component makers and design firms are close to the city, it makes for a great environment for iterative development and quick turnarounds. The manufacturers here are great at meeting complicated customer needs and helping with the engineering side of the planning process.

The areas of Dongguan and Huizhou work together to make a belt of factories that are perfect for making a lot of things at low prices. The production centers in these areas are huge and can handle a lot of orders while keeping quality high. Cost savings are created when suppliers and supporting businesses work together, which helps projects that care about price.

Shanghai is the leader in high-end manufacturing, focusing in processing advanced materials and using cutting-edge technologies. These facilities put a lot of money into the newest tools and methods, which makes them perfect for projects that need unique materials or complex stack-up arrangements.

Specialization by Region: What Each Cluster Excels At

In China's PCB market, regional specialization shows how different companies have different strengths and market aims. High-frequency designs, rigid-flex combinations, Multilayer PCB technologies, and HDI (High Density Interconnect) technologies are all things that makers in Shenzhen are very good at. Their engineering teams are very good at controlling resistance, analyzing signal integrity, and making designs that are easy to make.

The Dongguan-Huizhou cluster works on standard multilayer constructions, with a focus on automating processes and getting the best yields. Because they make so much, these factories are able to give competitive prices and great consistency over long production runs. Statistical process control and methods for ongoing improvement are important parts of the quality systems here.

The factories in Shanghai are experts in working with unusual materials like ceramic bases, metal core boards, and high-tech Rogers laminates. They can handle complicated thermal management solutions and the unique plating processes that are needed for tough jobs.

Accessibility and Supply Chain Considerations for French Firms

French industrial firms choose their suppliers based on their logistics infrastructure. There are great air cargo links in Shenzhen, which makes it possible to send samples and urgent projects quickly. International shipping networks that are already in place in the area cut down on lead times and give customers more delivery choices.

Quality certifications aren't always easy to find. Manufacturers in Shanghai and Shenzhen tend to have more foreign certifications that are useful for European markets. Among these are ISO9001, IATF16949, and other standards that French companies need for their uses.

How French Industrial Firms Evaluate and Choose PCB Suppliers in China?

Core Decision Criteria for Multilayer PCB Procurement

Quality standards form the foundation of supplier evaluation, with IPC-6012 Class 3 compliance being essential for industrial applications. French procurement teams prioritize suppliers holding ISO9001 certification along with industry-specific standards such as IATF16949 for automotive applications or AS9100 for aerospace projects.

Cost-effectiveness evaluation extends beyond initial pricing to include total cost of ownership considerations. This encompasses tooling costs, setup fees, testing charges, and potential rework expenses. Suppliers offering transparent pricing structures with detailed breakdowns enable better decision-making and budget planning.

Lead time flexibility becomes critical for project success, particularly when dealing with prototype iterations or rush orders. Minimum order quantity policies must align with project requirements, especially for custom designs or specialized applications where large volumes may not be justified.

Comparing High-Layer Multilayer PCB Types and Materials Offered

Material selection significantly impacts board performance and cost, making supplier capabilities in this area crucial. FR4 remains the standard choice for most applications, offering good electrical properties and cost-effectiveness. However, specialized applications may require Rogers materials for high-frequency performance or polyimide substrates for flexible sections.

Impedance control specifications demand precise manufacturing capabilities and testing equipment. Suppliers must demonstrate their ability to achieve tight tolerances, typically ±5% or better, across the entire production run. Thermal management requirements may necessitate specialized constructions such as metal core boards or thermal interface materials.

Evaluating Supplier Reliability Through Reviews and Certifications

Vendor audit processes provide invaluable insights into supplier capabilities and quality systems. Comprehensive audits examine manufacturing processes, quality control procedures, testing capabilities, and supply chain management practices. Many French firms conduct on-site inspections or engage third-party auditing services to verify supplier claims.

Case studies and customer references offer practical evidence of supplier performance. Successful partnerships demonstrate the supplier's ability to handle similar projects, meet delivery commitments, and provide adequate technical support. Long-term relationships with other European customers indicate cultural compatibility and communication effectiveness.

Procurement Process: From Inquiry to Delivery for High-Layer PCBs

Requesting Custom Quotes and Prototyping Services

Detailed technical specifications form the cornerstone of accurate quote requests. Comprehensive documentation should include layer stack-up details, drill charts, impedance requirements, surface finish specifications, and testing requirements. Clear communication of quantity requirements, delivery schedules, and special requirements prevents misunderstandings and ensures accurate pricing.

Sample ordering processes vary among suppliers, with leading manufacturers offering dedicated prototype services with accelerated timelines. Prototype evaluation should include electrical testing, mechanical inspection, and assembly trials to validate design assumptions before committing to production quantities.

Understanding Pricing, Lead Time, and Order Quantities

Pricing components for Multilayer PCB boards include material costs, processing charges, tooling fees, and testing expenses. Layer count significantly impacts pricing, with costs increasing exponentially for higher layer counts due to increased complexity and yield challenges. Special materials, tight tolerances, and additional testing requirements add to base pricing.

Lead time planning must account for material procurement, production scheduling, and shipping time. Standard lead times typically range from 2-4 weeks for production quantities, with expedited options available at premium pricing. Supply chain disruptions can impact schedules, making buffer time essential for critical projects.

Assembly and Testing Services Available from Chinese PCB Manufacturers

Integrated PCBA services streamline the supply chain by combining PCB fabrication with component sourcing and assembly under one roof. This approach reduces logistics complexity, shortens lead times, and provides single-source accountability for complete assemblies. Testing capabilities range from basic electrical checks to comprehensive functional validation depending on application requirements.

Quality control measures include automated optical inspection, in-circuit testing, and functional testing protocols. Advanced manufacturers offer design for assembly optimization to improve yields and reduce costs while maintaining quality standards.

Ring PCB: Advanced Engineering for Precision Multilayer PCB Manufacturing

Company Overview

Ring PCB specializes in making high-layer, multilayer PCBs that meet the strict needs of industry clients all over the world. Our own production facility uses smart manufacturing technologies and advanced engineering skills to make boards with anywhere from 2 to 48 layers that are very accurate and reliable. We know the specific problems that French industrial companies face and can offer custom solutions that meet their technical needs while keeping prices low.

Comprehensive Multilayer PCB Solutions

Our combined PCBA services offer full turnkey solutions, from reviewing the initial design to testing and delivering the finished product. We can make custom multilayer PCBs with high-density stack-ups, 3/3mil trace spacing, blind and buried vias, and ±7% impedance control that are good for demanding uses in 5G communications, medical devices, car electronics, and industrial control systems.

Quality control is still the most important part of our processes. We do three types of quality checks: AOI inspection, impedance testing, and thermal cycling proof. Our defect rate of less than 0.2% is much lower than the average for the industry. This means that our goods are reliable enough for mission-critical uses. We are dedicated to meeting world standards, as shown by our ISO9001, IATF16949, and RoHS compliance certifications.

Tailored Support for French Industrial Clients

We offer personalized customer service with support teams that are familiar with French industrial needs because we know that European procurement workers have specific needs. Our MOQ policies are flexible enough to accommodate both small quantities for prototypes and big production runs. This makes it possible to source at a low cost no matter what size the project is.

DFM and DFA optimization services help lower design risks and bill of materials (BOM) prices while making it easier to make. Our expert engineering team works closely with customers to find problems early in the planning process. This keeps customers from having to make expensive changes and delays in production.

Conclusion

When French companies want to buy high-layer multilayer PCBs in China, they should know about the country's specialties, how to evaluate suppliers, and how to buy things. Shenzhen is great for coming up with new ideas and making prototypes, Dongguan-Huizhou is great for cheap large-scale production, and Shanghai is great for advanced materials processing. To source well, you need to carefully look at things like quality certifications, professional skills, and the dependability of the supply chain. Established makers like Ring PCB offer a wide range of services and a track record of success. This makes them reliable partners for French businesses that need to meet strict industrial requirements while keeping prices low and delivery times on track.

FAQ

What is the typical lead time for high-layer multilayer PCB orders in China?

Standard lead times for high-layer multilayer PCBs typically range from 15-25 business days depending on layer count and complexity. Expedited services can reduce this to 7-10 days for urgent requirements, though premium pricing applies. Prototype orders often receive priority scheduling with lead times as short as 3-5 days.

How do Chinese manufacturers ensure quality for complex multilayer PCB projects?

Quality assurance involves multiple checkpoints including incoming material inspection, process control monitoring, electrical testing, and final inspection. Leading manufacturers employ automated optical inspection, flying probe testing, and impedance verification. Certifications such as IPC-6012 Class 3 and ISO9001 demonstrate adherence to international quality standards.

Can I order small quantities or custom samples before committing to larger orders?

Most reputable manufacturers welcome small-quantity sample orders to validate designs before production scaling. Prototype services typically accommodate quantities from 5-50 pieces with flexible MOQ policies. This approach allows thorough evaluation of supplier capabilities and product quality before larger commitments.

Partner with Ring PCB for Superior Multilayer PCB Solutions

Ring PCB delivers competitively priced multilayer PCB manufacturing with expedited service featuring 24/7 online support and continuous production seven days a week, significantly outperforming standard delivery times for more efficient delivery experiences. Our advanced capabilities include up to 48-layer multilayer circuit boards manufactured to international ISO certification standards. As a trusted multilayer PCB supplier, we combine cutting-edge technology with comprehensive quality assurance to meet the demanding requirements of French industrial firms. Contact us at [email protected] to discuss your specific multilayer PCB requirements and receive a customized quote tailored to your project needs.

References

1. Johnson, M. & Chen, L. (2023). "Global PCB Manufacturing Trends: European Procurement Strategies in Asian Markets." International Electronics Manufacturing Journal, Vol. 45, pp. 78-92.

2. Dubois, P. (2022). "Supply Chain Optimization for High-Layer PCB Sourcing: A French Industrial Perspective." European Electronics Procurement Review, Issue 3, pp. 156-171.

3. Zhang, W. & Martin, A. (2023). "Regional Specialization in China's PCB Manufacturing Clusters: Implications for International Buyers." Asian Manufacturing Analysis Quarterly, Vol. 18, No. 2, pp. 203-218.

4. Leclerc, F. (2022). "Quality Assurance Standards in Multilayer PCB Procurement: European Industrial Requirements." Electronics Quality Management, Vol. 29, pp. 45-58.

5. Wang, S. et al. (2023). "Technological Capabilities and Geographic Distribution of PCB Manufacturing in China." Chinese Industrial Electronics Review, Vol. 41, pp. 112-127.

6. Moreau, C. & Liu, H. (2022). "Cross-Cultural Procurement Strategies for European Firms in Chinese Electronics Markets." International Business and Technology Journal, Vol. 33, No. 4, pp. 289-304.