Grasping DFM in One-Stop PCBA Services

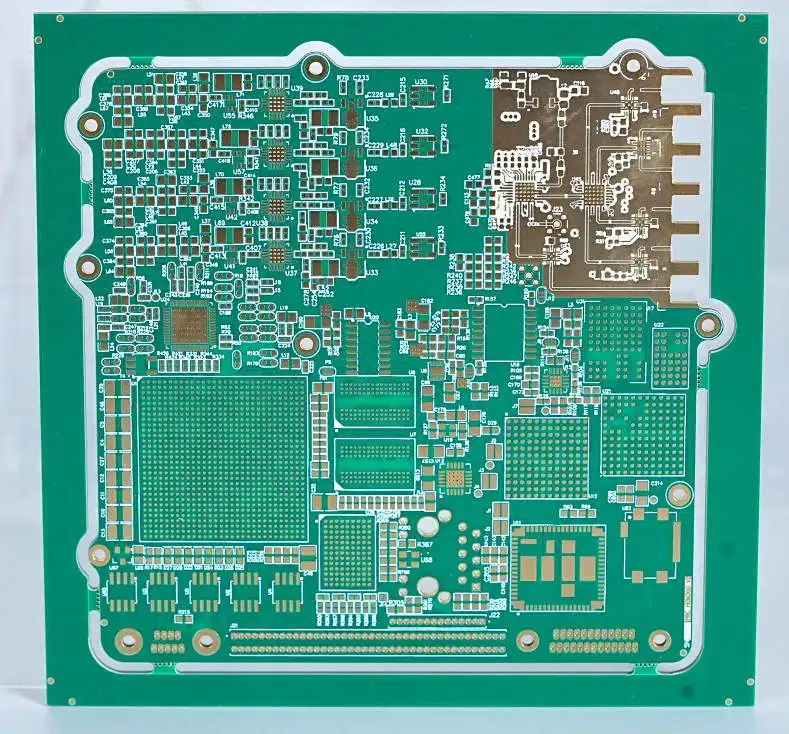

Design for Manufacturing (DFM) is a critical aspect of the one-stop PCBA service process. It involves creating PCB designs that are optimized for efficient production, assembly, and testing. By implementing DFM principles, manufacturers can significantly reduce production costs, improve product quality, and accelerate time-to-market.

In the context of one-stop PCBA services, DFM encompasses a wide range of considerations, from PCB layout and component selection to assembly processes and testing procedures. The goal is to create a design that not only meets functional requirements but also aligns with manufacturing capabilities and constraints.

Key Benefits of DFM in PCBA Projects

Implementing DFM rules in one-stop PCBA projects offers numerous advantages:

- Reduced manufacturing defects and rework

- Improved yield rates and production efficiency

- Lower overall production costs

- Enhanced product reliability and performance

- Faster time-to-market for new products

By addressing potential manufacturing issues early in the design phase, companies can avoid costly redesigns and production delays. This proactive approach is particularly valuable in complex PCBA projects involving high-density interconnect (HDI) boards or advanced packaging technologies.

Critical DFM Rules for PCB Layout and Design

When designing PCBs for one-stop PCBA services, several critical DFM rules should be followed to ensure manufacturability and assembly quality:

Component Placement and Orientation

Proper component placement is essential for efficient assembly and reliable operation. Key considerations include:

- Maintaining adequate spacing between components to allow for pick-and-place equipment and wave soldering

- Aligning components in the same direction to simplify automated assembly

- Grouping similar components together to optimize production flow

- Ensuring sufficient clearance for automatic optical inspection (AOI) and functional testing

Trace Width and Spacing

Optimizing trace width and spacing is crucial for manufacturability and electrical performance:

- Adhere to minimum trace width and spacing requirements based on the PCB fabrication process

- Consider current-carrying capacity when determining trace widths for power and ground planes

- Maintain consistent trace widths and spacing throughout the design to simplify manufacturing

- Use appropriate copper weight and layer stack-up to meet impedance control requirements

Via Design and Placement

Proper via design is essential for reliable interconnections and manufacturability:

- Follow minimum via size and aspect ratio guidelines based on the PCB technology (e.g., through-hole, blind, or buried vias)

- Avoid placing vias under surface-mount components to prevent solder wicking

- Use teardrops at via-to-trace connections to improve mechanical strength

- Consider via-in-pad design for high-density boards, but be aware of potential manufacturing challenges

Advanced DFM Considerations for Complex PCBA Projects

As PCBA technology advances, additional DFM considerations become necessary for complex projects:

High-Speed Design Considerations

For high-speed PCBAs, additional DFM rules must be observed:

- Implement controlled impedance routing for critical signal paths

- Use appropriate stack-up design to minimize crosstalk and maintain signal integrity

- Consider electromagnetic compatibility (EMC) requirements in the PCB layout

- Apply proper grounding and power distribution techniques to reduce noise and improve signal quality

Thermal Management

Effective thermal management is crucial for high-power PCBAs:

- Design adequate thermal relief for power components and high-current traces

- Incorporate thermal vias and copper planes to improve heat dissipation

- Consider the use of metal-core or aluminum PCBs for high-power applications

- Evaluate the need for additional cooling solutions, such as heatsinks or fans

Flex and Rigid-Flex PCB Considerations

Flexible and rigid-flex PCBs require special DFM considerations:

- Design bend radii to meet manufacturing and reliability requirements

- Use appropriate materials and layer stack-ups for flex and rigid sections

- Consider the impact of flexing on component placement and solder joint reliability

- Implement strain relief features to protect flex-to-rigid transitions

By adhering to these advanced DFM rules, manufacturers can ensure the successful production of complex PCBAs using one-stop PCBA services. This approach enables the creation of high-performance, reliable products that meet the demands of modern electronic systems.

Conclusion

Implementing essential DFM rules is crucial for successful one-stop PCBA projects. By carefully considering component placement, trace design, via configuration, and advanced manufacturing requirements, companies can optimize their PCB designs for efficient production and assembly. This proactive approach not only reduces manufacturing costs but also improves product quality and reliability.

When selecting a PCBA manufacturer or supplier, it's essential to choose a partner with extensive experience in DFM optimization and advanced PCB technologies. Look for suppliers that offer comprehensive one-stop PCBA services, including PCB fabrication, component sourcing, assembly, and testing. By partnering with a skilled PCBA manufacturer, you can ensure that your designs are optimized for production and meet the highest quality standards.

FAQ

What is the difference between PCB and PCBA?

PCB (Printed Circuit Board) is the bare board without components, while PCBA (Printed Circuit Board Assembly) is the completed board with all components soldered in place.

What types of PCBs can be manufactured using one-stop PCBA services?

One-stop PCBA services typically cover a wide range of PCB types, including multilayer, high-density interconnect (HDI), flex, rigid-flex, and metal-core PCBs.

How does automated optical inspection (AOI) improve PCBA quality?

AOI systems use high-resolution cameras and advanced algorithms to detect defects in PCB assembly, such as missing components, incorrect placements, or solder joint issues, ensuring high-quality production.

Comprehensive One-Stop PCBA Solutions | Ring PCB

Ring PCB offers state-of-the-art one-stop PCBA services, combining cutting-edge PCB fabrication, efficient component sourcing, precision SMT assembly, and rigorous quality control. Our expert engineering team optimizes designs for manufacturability, reducing risks and costs. With advanced X-ray inspection, AOI testing, and 100% functional validation, we ensure zero-defect delivery for even the most complex PCBA projects. Trust our ISO-certified factory for your high-reliability, multi-layer, and HDI PCB manufacturing needs. Contact us at [email protected] for unparalleled PCBA solutions.

References

1. Smith, J. (2022). Advanced Design for Manufacturing Techniques in PCB Assembly. Journal of Electronics Manufacturing, 15(2), 78-92.

2. Johnson, R., & Williams, T. (2021). Optimizing PCB Layout for High-Speed and High-Density Applications. IEEE Transactions on Electronics Packaging Manufacturing, 44(3), 301-315.

3. Chen, L., et al. (2023). Thermal Management Strategies for High-Power PCB Assemblies. International Journal of Thermal Sciences, 178, 107654.

4. Brown, A. (2022). Design Considerations for Flex and Rigid-Flex PCBs in Modern Electronics. Flexible Electronics, 6(2), 25-39.

5. Anderson, D., & Miller, S. (2023). Implementing Effective DFM Rules in One-Stop PCBA Services. Proceedings of the International Symposium on Electronic Manufacturing Technology, 112-125.