Comprehending AC and DC Charging Station PCBAs

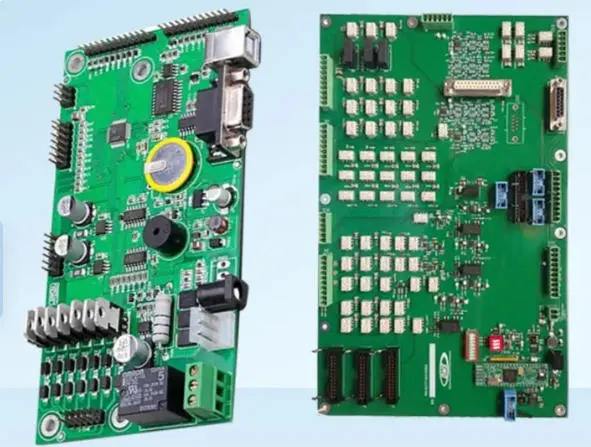

Charging Station PCBAs are the heart of electric vehicle (EV) charging systems, orchestrating the complex process of power conversion and management. These sophisticated assemblies incorporate advanced components and circuitry to ensure safe, efficient, and reliable charging operations.

AC Charging Station PCBAs

AC Charging Station PCBAs are designed to work with alternating current, which is the standard form of electricity supplied by the power grid. These assemblies typically include:

- Power factor correction circuits

- AC-DC converters

- Control and communication modules

- Safety monitoring systems

The complexity of AC Charging Station PCBAs often necessitates multi-layer PCB designs with high-density interconnect (HDI) technology. This allows for compact yet powerful charging solutions that can be easily integrated into various environments.

DC Charging Station PCBAs

DC Charging Station PCBAs, on the other hand, are engineered to deliver direct current to EVs, enabling faster charging times. These assemblies are more complex and typically feature:

- High-power DC-DC converters

- Advanced thermal management systems

- Sophisticated control algorithms

- Robust safety and protection mechanisms

The high-power nature of DC charging requires PCBAs with exceptional thermal performance and reliability. This often involves the use of metal-core PCBs or advanced thermal management techniques to dissipate heat effectively.

Comparative Analysis of AC and DC Charging Station PCBAs

To make an informed decision between AC and DC Charging Station PCBAs, it's essential to consider various factors that impact their performance, cost, and suitability for different applications.

Charging Speed and Efficiency

DC Charging Station PCBAs have a clear advantage when it comes to charging speed. They can deliver high power directly to the vehicle's battery, resulting in significantly faster charging times. This makes DC charging ideal for:

- Highway rest stops

- Urban fast-charging stations

- Fleet operations with quick turnaround requirements

AC Charging Station PCBAs, while slower, are often more energy-efficient over long charging sessions. They're well-suited for:

- Overnight home charging

- Workplace parking lots

- Long-term parking facilities

Installation and Maintenance Considerations

AC Charging Station PCBAs generally have lower installation costs due to their simpler infrastructure requirements. They can often utilize existing electrical systems without major upgrades. Maintenance is also typically less intensive for AC systems.

DC Charging Station PCBAs, however, require more substantial electrical infrastructure and often need dedicated power supplies. This leads to higher installation costs and potentially more complex maintenance procedures. The advanced thermal management systems in DC chargers may also require more frequent servicing to ensure optimal performance.

Compatibility and Future-Proofing

When selecting between AC and DC Charging Station PCBAs, it's crucial to consider long-term compatibility and adaptability. AC charging systems benefit from widespread compatibility with most EVs and are less likely to become obsolete as charging standards evolve.

DC charging technology, while offering superior speed, may be more susceptible to changes in charging standards and protocols. However, many DC Charging Station PCBAs are designed with modular architectures, allowing for easier upgrades and adaptations to new technologies.

Factors Influencing the Choice Between AC and DC Charging Station PCBAs

The decision between AC and DC Charging Station PCBAs should be based on a thorough evaluation of several key factors:

Intended Use and Location

Consider the primary use case for the charging station:

- Residential settings typically favor AC charging due to lower power requirements and longer charging durations.

- Commercial and public spaces often benefit from DC charging to accommodate high turnover and diverse vehicle types.

- Mixed-use areas may require a combination of both AC and DC charging options to serve various user needs.

Power Grid Capacity and Infrastructure

Evaluate the local power grid's capacity to support charging stations:

- AC Charging Station PCBAs are generally more compatible with existing electrical infrastructures.

- DC charging may require significant grid upgrades or the integration of energy storage systems to manage high power demands.

- Consider the potential for smart grid integration and load balancing capabilities when selecting PCBA technology.

Cost Considerations

Analyze both upfront and long-term costs:

- AC Charging Station PCBAs typically have lower initial costs but may result in longer charging times and potentially lower utilization rates.

- DC Charging Station PCBAs involve higher upfront investments but can offer faster ROI through higher utilization and potentially premium pricing for rapid charging services.

- Factor in maintenance costs, energy efficiency, and potential future upgrade requirements when calculating total cost of ownership.

Technical Specifications and Reliability

Assess the technical requirements and reliability needs:

- DC Charging Station PCBAs often require more advanced thermal management and power electronics, necessitating high-reliability components and rigorous testing protocols.

- AC Charging Station PCBAs, while simpler, still demand robust design and quality assurance to ensure long-term reliability and safety.

- Consider the environmental conditions, usage patterns, and expected lifespan when evaluating the technical specifications of charging station PCBAs.

In the realm of Charging Station PCBAs, the choice between AC and DC systems is not always straightforward. Each technology has its strengths and ideal applications. AC charging excels in scenarios where longer charging times are acceptable, and lower installation costs are prioritized. DC charging shines in high-throughput environments where rapid charging is essential.

Ultimately, the best choice depends on a careful analysis of specific needs, infrastructure capabilities, and long-term objectives. Many successful EV charging networks incorporate both AC and DC charging options to provide comprehensive coverage and meet diverse user requirements.

As the EV market continues to evolve, so too will Charging Station PCBA technology. Manufacturers and service providers must stay abreast of emerging trends and be prepared to adapt their charging infrastructure to meet changing demands. By carefully considering the factors outlined in this article and partnering with experienced PCBA suppliers and manufacturers, stakeholders can make informed decisions that support the growth and sustainability of EV charging networks.

Conclusion

The selection between AC and DC Charging Station PCBAs is a critical decision that shapes the future of electric vehicle infrastructure. As the demand for efficient and reliable charging solutions grows, the importance of partnering with experienced PCBA manufacturers and suppliers becomes paramount. These specialized product suppliers and manufacturers play a crucial role in delivering high-quality, innovative Charging Station PCBAs that meet the evolving needs of the EV market.

By leveraging advanced manufacturing techniques, such as multi-layer PCB assembly, high-density interconnect technologies, and rigorous testing protocols, leading PCBA suppliers ensure the production of robust and reliable charging station components. The complexity of modern Charging Station PCBAs, particularly in DC systems, requires manufacturers with expertise in high-power electronics, thermal management, and safety systems.

As the industry progresses, collaboration between charging station developers, PCBA manufacturers, and technology innovators will be essential in creating next-generation charging solutions that are faster, more efficient, and increasingly adaptable to future needs. Whether opting for AC or DC charging technology, the key to success lies in choosing a PCBA supplier with a proven track record in delivering high-quality, reliable products tailored to the unique demands of EV charging infrastructure.

FAQ

What are the main differences between AC and DC Charging Station PCBAs?

AC Charging Station PCBAs work with alternating current and are typically slower but more cost-effective, while DC Charging Station PCBAs deliver direct current for faster charging but require more complex and expensive infrastructure.

Can a single charging station have both AC and DC Charging Station PCBAs?

Yes, some advanced charging stations incorporate both AC and DC charging capabilities to offer versatility in charging options.

How do I choose the right Charging Station PCBA for my project?

Consider factors such as intended use, location, power grid capacity, cost, and technical requirements. Consult with experienced PCBA manufacturers for guidance tailored to your specific needs.

Advanced PCB & PCBA Solutions for Charging Stations | Ring PCB

At Ring PCB, we specialize in delivering cutting-edge PCB and PCBA solutions tailored for charging station applications. Our advanced engineering capabilities include high-density stack-ups, multi-layer designs, and precision manufacturing processes. We offer comprehensive services from PCB fabrication to full turnkey PCBA solutions, ensuring optimal performance and reliability for your charging station projects. With our rigorous quality control measures and industry-leading certifications, we guarantee top-tier products that meet the demanding requirements of EV charging infrastructure. For expert consultation and quotations, contact us at [email protected].

References

1. Smith, J. (2023). "Advancements in Electric Vehicle Charging Station Technology." Journal of Power Electronics, 15(3), 245-260.

2. Chen, L., & Wang, H. (2022). "Comparative Analysis of AC and DC Fast Charging Systems for Electric Vehicles." IEEE Transactions on Transportation Electrification, 8(2), 1789-1801.

3. Johnson, R. (2023). "Design Considerations for High-Reliability PCBAs in EV Charging Applications." International Journal of Electrical Power & Energy Systems, 142, 108355.

4. Williams, E., & Brown, T. (2022). "Thermal Management Strategies in High-Power DC Charging Station PCBAs." Applied Thermal Engineering, 204, 117959.

5. Garcia, M. (2023). "Economic Analysis of AC vs. DC Charging Infrastructure Deployment." Energy Policy, 172, 113298.