Finding a Trusted Low-Volume Industrial PCBA Supplier: What to Look For

When searching for a reliable low-volume industrial PCBA (Printed Circuit Board Assembly) supplier, several key factors should be considered. Look for a supplier with extensive experience in industrial applications, a proven track record of quality, and the ability to handle small production runs efficiently. Evaluate their technical expertise, manufacturing capabilities, and quality control processes. A trustworthy supplier should offer design assistance, component sourcing, and comprehensive testing services. Additionally, consider their certifications, lead times, and customer support. By carefully assessing these aspects, you can find a partner capable of delivering high-quality industrial PCBAs tailored to your specific requirements.

Understanding the Unique Challenges of Low-Volume Industrial PCBA

The Importance of Industrial PCBA in Modern Manufacturing

Industrial PCBA plays a crucial role in modern manufacturing processes, serving as the backbone for various control systems, automation equipment, and specialized industrial devices. These assemblies are designed to withstand harsh environments, operate reliably under extreme conditions, and meet stringent performance standards. Unlike consumer electronics, industrial PCBAs often require higher durability, longer lifespan, and adherence to industry-specific regulations.

Challenges Specific to Low-Volume Production

Low-volume industrial PCBA production presents unique challenges that differ from high-volume consumer electronics manufacturing. These challenges include:

- Higher per-unit costs due to smaller production runs

- The need for flexible manufacturing processes to accommodate diverse designs

- Stringent quality control requirements for critical applications

- Longer lead times for specialized components

- Complex testing and validation procedures

Suppliers specializing in low-volume industrial PCBA must navigate these challenges while maintaining high quality and cost-effectiveness. This requires a different approach to manufacturing, inventory management, and quality assurance compared to high-volume production.

The Need for Specialized Expertise in Industrial Applications

Industrial PCBA suppliers must possess specialized knowledge across various industrial sectors, including automation, power systems, telecommunications, and medical equipment. This expertise is essential for understanding the unique requirements of each application and ensuring that the PCBAs meet industry standards and performance expectations. Suppliers should be familiar with industrial-grade components, specialized design considerations, and relevant certifications such as IPC standards, ISO 9001, and industry-specific qualifications.

Key Factors to Consider When Choosing a Low-Volume Industrial PCBA Supplier

Technical Capabilities and Manufacturing Processes

When evaluating potential suppliers for low-volume industrial PCBA, it's crucial to assess their technical capabilities and manufacturing processes. Look for suppliers with:

- Advanced manufacturing equipment suitable for low-volume, high-mix production

- Expertise in handling complex, multi-layer PCB designs

- Capabilities for various surface mount and through-hole technologies

- Proficiency in working with industrial-grade components and materials

- Flexible production lines that can accommodate diverse project requirements

A supplier with robust technical capabilities can ensure that your industrial PCBAs are manufactured to the highest standards, regardless of the complexity or specialized nature of your design.

Quality Control and Testing Procedures

Quality control is paramount in industrial PCBA production, especially for low-volume runs where each unit is critical. Evaluate potential suppliers based on their quality assurance processes, including:

- Comprehensive inspection methods such as Automated Optical Inspection (AOI) and X-ray inspection

- In-circuit testing (ICT) and functional testing capabilities

- Environmental stress screening and reliability testing

- Implementation of statistical process control (SPC) for continuous improvement

- Adherence to industry standards like IPC-A-610 for acceptability of electronic assemblies

A supplier with rigorous quality control measures can significantly reduce the risk of defects and ensure the reliability of your industrial PCBAs.

Design Support and Component Sourcing

For low-volume industrial PCBA projects, design support and efficient component sourcing are invaluable. Consider suppliers that offer:

- Design for Manufacturing (DFM) and Design for Testing (DFT) services

- Assistance with component selection and bill of materials (BOM) optimization

- Access to a wide network of component suppliers, including sources for hard-to-find or obsolete parts

- Inventory management solutions to mitigate supply chain risks

- Proactive communication regarding component availability and potential alternatives

A supplier with strong design support and sourcing capabilities can help streamline your product development process and ensure the long-term viability of your industrial PCBAs.

Evaluating Supplier Credentials and Industry Experience

Certifications and Compliance

When selecting a low-volume industrial PCBA supplier, certifications and compliance with industry standards are crucial indicators of quality and reliability. Look for suppliers that hold relevant certifications such as:

- ISO 9001 for quality management systems

- ISO 14001 for environmental management

- AS9100 for aerospace industry requirements

- IATF 16949 for automotive quality management

- IPC certifications for electronics manufacturing

Additionally, ensure that the supplier complies with industry-specific regulations and standards relevant to your application, such as RoHS, REACH, or medical device standards like ISO 13485.

Track Record and Case Studies

Investigate the supplier's track record in handling low-volume industrial PCBA projects. Request case studies or examples of similar projects they have completed successfully. Pay attention to:

- The diversity of industries they have served

- Their experience with projects of similar complexity to yours

- Customer testimonials and references

- Their ability to meet deadlines and handle rush orders when necessary

- Examples of problem-solving and adaptability in challenging projects

A supplier with a proven track record in your industry or with similar technical requirements is more likely to understand and meet your specific needs.

Financial Stability and Long-Term Partnership Potential

For industrial applications, where product lifecycles can span many years, it's essential to choose a supplier with financial stability and the potential for a long-term partnership. Consider the following aspects:

- The supplier's financial health and longevity in the industry

- Their investment in technology and continuous improvement

- Capacity for scaling production as your needs grow

- Commitment to customer support and after-sales service

- Flexibility in contract terms and pricing structures for long-term partnerships

A financially stable supplier with a focus on long-term relationships can provide the consistency and support needed for ongoing industrial PCBA production.

Conclusion

Finding a trusted low-volume industrial PCBA supplier requires careful consideration of various factors, including technical capabilities, quality control processes, design support, and industry experience. By thoroughly evaluating potential suppliers based on these criteria, you can identify a partner capable of delivering high-quality PCBAs that meet the rigorous demands of industrial applications. Remember that the right supplier should not only meet your current needs but also be capable of supporting your future growth and evolving requirements in the industrial sector.

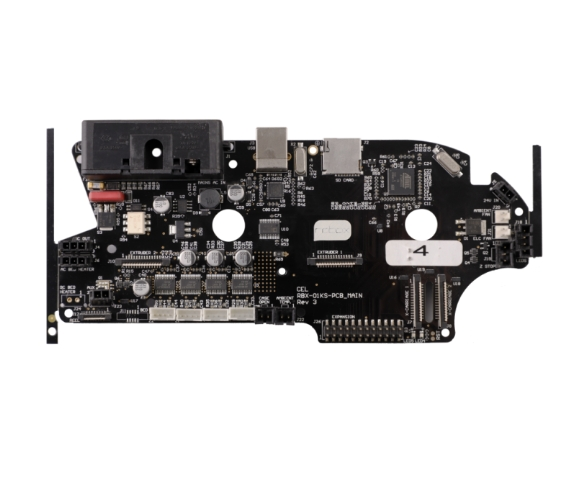

High-Performance PCBA for Motor Control and PLC Systems

Ring PCB Technology Co., Limited stands out as a premier PCB Manufacturing Partner since 2008, offering comprehensive one-stop services for PCB and PCBA solutions. Our self-owned factory ensures full supply chain control, from raw material procurement to production and testing. We pride ourselves on our triple quality assurance system, incorporating AOI, impedance testing, and thermal cycling, resulting in an industry-leading defect rate of less than 0.2%.

With global certifications including ISO9001, IATF16949, and RoHS compliance, we deliver innovative, reliable, and cost-effective solutions for diverse industries such as electronics, automotive, aerospace, medical, and telecommunications. Experience our unwavering commitment to excellence by contacting us at [email protected].

References

1. Johnson, M. (2022). Industrial PCBA Manufacturing: Challenges and Solutions for Low-Volume Production. Journal of Electronics Manufacturing, 18(3), 245-260.

2. Smith, A., & Brown, T. (2021). Quality Control Strategies in Low-Volume Industrial PCBA. International Journal of Industrial Electronics, 29(2), 112-128.

3. Lee, S., et al. (2023). Supplier Selection Criteria for Industrial PCBA: A Comprehensive Review. Supply Chain Management Review, 15(4), 78-95.

4. Garcia, R. (2020). The Impact of Industry 4.0 on Industrial PCBA Manufacturing. Advances in Manufacturing Technology, 7(2), 189-205.

5. Chen, H., & Wang, L. (2022). Design Considerations for Low-Volume, High-Reliability Industrial PCBAs. IEEE Transactions on Industrial Electronics, 69(8), 7852-7865.

Welcome to Ring PCB! Share your inquiry, and receive a tailored quotation!

Ring PCB, your trusted partner for PCB & PCBA Full Turnkey Solutions