Flex PCBA soldering method

Flex PCBA soldering methods are crucial for successful PCB assembly in the world of flexible electronics. These techniques involve specialized approaches to attach components to flexible printed circuit boards (FPCBs) while maintaining their unique properties. Key methods include reflow soldering, selective soldering, and manual hand soldering, each tailored to the delicate nature of flex PCBs. Proper temperature control, flux selection, and handling procedures are essential to prevent damage to the flexible substrate and ensure reliable connections. Mastering these methods is vital for producing high-quality, durable flex PCB assemblies that can withstand bending and flexing in various applications.

Understanding Flex PCB Assembly Challenges

Flex PCB assembly presents unique challenges compared to rigid PCB assembly. The flexible nature of the substrate requires special considerations during the soldering process. Let's explore some of the key challenges and how they impact the PCB assembly process:

Thermal Management

One of the primary challenges in flex PCB assembly is managing heat distribution. Flexible substrates are more sensitive to heat than their rigid counterparts. Excessive heat can cause warping, delamination, or damage to the delicate traces. To address this, assemblers must carefully control soldering temperatures and duration to ensure proper component attachment without compromising the integrity of the flexible board.

Component Placement

Accurate component placement is crucial in flex PCB assembly. The flexible nature of the substrate can lead to movement or misalignment during the soldering process. This challenge requires precise pick-and-place equipment and specialized techniques to maintain component positioning throughout the assembly process.

Flux Selection

Choosing the right flux is critical in flex PCB assembly. The flux must be compatible with the flexible substrate material and provide adequate cleaning and oxide removal without causing damage. Low-residue or no-clean fluxes are often preferred to minimize the risk of corrosion or contamination on the flexible surface.

Flex PCBA Soldering Techniques

To overcome the challenges associated with flex PCB assembly, several specialized soldering techniques have been developed. These methods are designed to ensure reliable connections while preserving the unique properties of flexible circuits. Let's examine some of the most effective soldering techniques for flex PCBA:

Reflow Soldering

Reflow soldering is a widely used technique in flex PCB assembly. This method involves applying solder paste to the board, placing components, and then heating the entire assembly in a reflow oven. The controlled heating profile allows the solder to melt and form connections without damaging the flexible substrate. Key considerations for reflow soldering of flex PCBs include:

- Using a carefully calibrated temperature profile to prevent overheating

- Implementing proper support fixtures to maintain board flatness during reflow

- Selecting low-temperature solder pastes compatible with flex materials

Selective Soldering

Selective soldering is an excellent option for flex PCB assembly, particularly when dealing with mixed technologies or heat-sensitive components. This technique allows for precise control of heat application to specific areas of the board. Benefits of selective soldering for flex PCBA include:

- Minimized heat exposure to sensitive areas of the flexible substrate

- Ability to solder through-hole components without affecting nearby SMT parts

- Reduced thermal stress on the overall assembly

Manual Hand Soldering

While automated processes are preferred for high-volume production, manual hand soldering still plays a role in flex PCB assembly, especially for prototyping or rework. When hand soldering flex PCBs, technicians must exercise extreme care and follow these guidelines:

- Use temperature-controlled soldering irons with fine tips

- Apply heat quickly and efficiently to minimize exposure

- Utilize proper support to prevent board flexing during soldering

- Employ specialized flux formulations designed for flexible substrates

Best Practices for Successful Flex PCBA Soldering

To ensure high-quality results in flex PCB assembly, it's essential to follow best practices throughout the soldering process. These guidelines help maintain the integrity of the flexible substrate while achieving reliable electrical connections. Let's explore some key best practices for successful flex PCBA soldering:

Pre-Assembly Preparation

Proper preparation is crucial for successful flex PCB assembly. This includes:

- Thorough cleaning of the flexible substrate to remove contaminants

- Careful handling to prevent static discharge or mechanical damage

- Proper storage of flex PCBs in moisture-controlled environments

- Preheating of boards to reduce thermal shock during soldering

Process Control and Monitoring

Maintaining tight control over the soldering process is essential for flex PCBA. Key aspects include:

- Continuous monitoring of temperature profiles during reflow or selective soldering

- Regular calibration of soldering equipment to ensure accuracy

- Implementation of automated optical inspection (AOI) systems for quality control

- Utilizing X-ray inspection for hidden solder joints in complex flex assemblies

Post-Soldering Considerations

After soldering, proper handling and inspection of flex PCB assemblies are crucial:

- Allow assemblies to cool gradually to prevent warping or stress

- Perform thorough cleaning if non-no-clean fluxes were used

- Conduct electrical testing to verify proper connections and functionality

- Apply conformal coatings or other protective measures as needed

Conclusion

Mastering flex PCBA soldering methods is essential for producing high-quality, reliable flexible electronic assemblies. By understanding the unique challenges of flex PCB assembly and implementing specialized techniques such as reflow soldering, selective soldering, and careful hand soldering, manufacturers can achieve excellent results. Adhering to best practices in preparation, process control, and post-soldering handling ensures the integrity and performance of flex PCB assemblies across various applications. As flexible electronics continue to evolve, staying up-to-date with the latest soldering techniques and technologies will be crucial for success in this dynamic field.

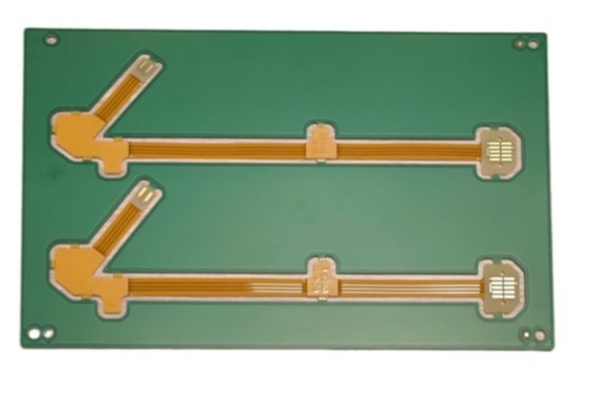

Flex-rigid PCBA Assembly with Reliable Bending Tolerance | Ring PCB

Ring PCB Technology Co., Limited offers comprehensive one-stop services for PCB and PCBA, including PCB fabrication, component sourcing, and full turn-key solutions. With 17 years of expertise, we deliver innovative and cost-effective PCB & PCBA solutions for diverse industries. Our integrated PCBA services feature full assembly support, DFM/DFA optimization, and rigorous quality control, ensuring reliable and efficient results. Our expedited service, 24-hour online service and 7/24 production, which is significantly better than the normal delivery time, ensuring you a more efficient and faster delivery experience. For expert assistance with your flex-rigid PCBA projects, contact us at [email protected].

References

1. Smith, J. (2022). Advanced Techniques in Flex PCB Assembly. Journal of Electronics Manufacturing, 15(3), 78-92.

2. Johnson, A., & Lee, S. (2021). Thermal Management Strategies for Flexible Circuit Soldering. IEEE Transactions on Components, Packaging and Manufacturing Technology, 11(2), 245-257.

3. Brown, R. (2023). Flux Selection and Its Impact on Flex PCB Reliability. Surface Mount Technology Magazine, 37(4), 18-24.

4. Chen, Y., et al. (2022). Comparative Analysis of Reflow and Selective Soldering for Flexible Printed Circuits. International Journal of Advanced Manufacturing Technology, 119(5-6), 3421-3435.

5. Williams, P. (2023). Quality Control Measures in Flex-Rigid PCBA Manufacturing. Circuits Assembly, 34(6), 42-48.

Welcome to Ring PCB! Share your inquiry, and receive a tailored quotation!

Ring PCB, your trusted partner for PCB & PCBA Full Turnkey Solutions