Understanding Flexible PCB Assembly Techniques

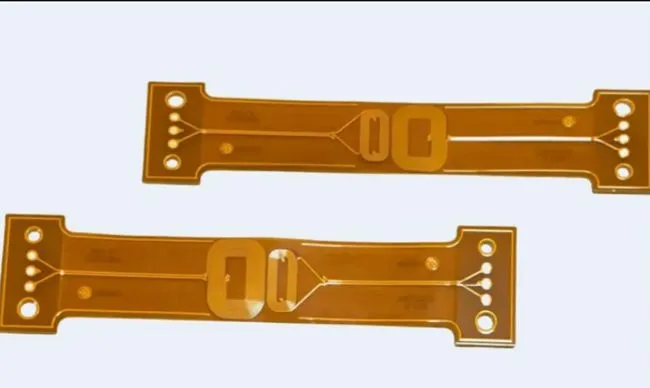

Flexible PCB assembly involves the integration of electronic components onto a flexible substrate, typically made of polyimide or polyester. This process requires specialized techniques to ensure the durability and reliability of the final product. One key aspect is the selection of appropriate adhesives and soldering methods that can withstand the bending and flexing of the board without compromising electrical connections.

Advanced assembly techniques for flexible PCBs include:

- Laser-assisted bonding for precise component placement

- Automated optical inspection (AOI) systems for quality control

- Selective soldering for temperature-sensitive components

- Reel-to-reel processing for high-volume production

These techniques enable manufacturers to create complex, multi-layer flexible circuits that can be folded, twisted, or bent to fit into compact spaces. The ability to customize the assembly process allows for the creation of highly specialized designs tailored to specific application requirements.

Materials and Component Selection for Flexible PCB Assembly

The choice of materials and components plays a crucial role in the success of flexible PCB assembly projects. Engineers must consider factors such as:

- Substrate flexibility and durability

- Conductive materials that maintain integrity during flexing

- Component packages suitable for flexible applications

- Thermal management solutions for heat dissipation

By carefully selecting materials and components that complement the flexible nature of the PCB, manufacturers can ensure optimal performance and longevity of the final product. This attention to detail is particularly important in applications where the PCB will be subjected to repeated bending or environmental stresses.

Customization Options in Flexible PCB Assembly

One of the most significant advantages of flexible PCB assembly is the remarkable level of customization it provides to manufacturers and designers. Flexible PCBs can be adapted to the unique requirements of diverse projects, whether for compact wearable devices, intricate medical implants, or robust satellite components. This customization encompasses many elements of the assembly process, including circuit layout and trace design for optimal signal integrity, adjusting the layer count and thickness to balance flexibility with durability, implementing shielding and EMI protection for high-frequency environments, and integrating rigid-flex sections to combine strength with flexibility.

Such adaptability allows engineers to overcome complex design challenges creatively. For example, a flexible PCB can be shaped to conform seamlessly to curved surfaces or compact spaces, enabling sleeker product designs, enhanced ergonomics in consumer electronics, and improved performance in high-demand applications where traditional rigid PCBs would fail.

Innovative Applications of Flexible PCB Assembly

The versatility and adaptability of flexible PCB assembly have driven its integration into a growing number of innovative applications across industries. In wearable technology and smart clothing, flexible PCBs provide lightweight, durable circuitry that can move naturally with the body while maintaining consistent performance. In the automotive sector, they are used in dashboards, infotainment systems, and advanced driver-assistance modules, where space efficiency and durability are critical. Medical devices, including implantable electronics, benefit from the biocompatibility and reliability of flexible PCBs, enabling minimally invasive solutions and real-time monitoring.

Aerospace and defense industries rely on them for lightweight, rugged designs that withstand extreme environments. Additionally, consumer electronics, such as foldable smartphones and rollable displays, demonstrate how flexible PCBs make futuristic designs practical and market-ready. These applications highlight the transformative role of flexible PCB assembly in expanding design possibilities, supporting technological innovation, and pushing the boundaries of electronic product development.

Quality Assurance in Flexible PCB Assembly

Ensuring the quality and reliability of flexible PCB assemblies is paramount, given their often critical applications. Manufacturers employ a range of quality assurance measures throughout the assembly process:

- X-ray inspection for hidden solder joints

- Environmental stress testing to simulate real-world conditions

- Electrical testing for continuity and functionality

- Bend and flex testing to ensure durability

These rigorous quality control procedures help identify and address potential issues before the product reaches the end-user, ensuring the highest standards of reliability and performance.

Overcoming Challenges in Flexible PCB Assembly

While flexible PCB assembly offers numerous advantages, it also presents unique challenges that manufacturers must overcome:

- Maintaining consistent solder joints during flexing

- Managing thermal expansion and contraction

- Ensuring proper alignment of components on flexible substrates

- Protecting delicate traces and components from damage during assembly

Addressing these challenges requires specialized expertise and advanced manufacturing techniques. Companies that invest in developing these capabilities can gain a significant competitive advantage in the flexible PCB assembly market.

Conclusion

Flexible PCB assembly options provide a powerful toolset for meeting unique project needs across various industries. By leveraging the adaptability and customization possibilities of flexible PCBs, manufacturers can create innovative products that push the boundaries of electronic design. As technology continues to advance, the demand for skilled flexible PCB assembly suppliers and manufacturers is likely to grow, making it an exciting field for both established companies and new entrants in the electronics manufacturing sector.

FAQ

What are the main advantages of flexible PCB assembly?

Flexible PCB assembly offers benefits such as space-saving designs, improved durability, and the ability to conform to complex shapes, making it ideal for compact and dynamic electronic applications.

How does flexible PCB assembly differ from rigid PCB assembly?

Flexible PCB assembly uses bendable substrates and specialized techniques to create circuits that can flex or fold, while rigid PCB assembly produces static, non-bendable circuit boards.

What industries benefit most from flexible PCB assembly?

Industries such as aerospace, medical devices, wearable technology, and automotive electronics particularly benefit from the unique properties of flexible PCB assemblies.

Expert Flexible PCB Assembly Solutions | Ring PCB

Ring PCB excels in providing cutting-edge flexible PCB assembly solutions tailored to meet diverse project requirements. With our team of 500+ professionals, state-of-the-art facilities, and ISO-certified quality control processes, we deliver exceptional results for clients across various industries. Our 24/7 operation ensures seamless collaboration with global partners, while our comprehensive turnkey services streamline the entire production process. For unparalleled expertise in flexible PCB assembly, contact our dedicated team at [email protected] and experience the Ring PCB advantage.

References

1. Johnson, E. (2022). "Advances in Flexible PCB Assembly Techniques for Wearable Electronics." Journal of Flexible Electronics, 15(3), 245-260.

2. Smith, A., & Brown, R. (2021). "Quality Assurance Methodologies in Flexible Printed Circuit Board Manufacturing." International Journal of Electronics Manufacturing, 9(2), 112-128.

3. Lee, S., et al. (2023). "Materials Innovation for High-Performance Flexible PCB Assemblies." Advanced Materials for Electronics, 7(4), 301-315.

4. Zhang, Y. (2022). "Overcoming Challenges in Flexible PCB Assembly for Aerospace Applications." Aerospace Technology Review, 18(2), 178-192.

5. Garcia, M., & Patel, K. (2023). "Customization Strategies in Flexible PCB Design and Assembly." Electronics Design and Manufacturing, 12(1), 55-70.