Flexible PCB Assembly Services for Smart Tech Products

Flexible PCB Assembly has revolutionized the world of smart tech products, offering unparalleled versatility and efficiency. These bendable circuit boards are the backbone of modern wearables, medical devices, and compact electronics. As demand for sleeker, more adaptable devices grows, manufacturers are increasingly turning to flexible PCB solutions. This article delves into the intricacies of flexible PCB assembly, its applications in smart technology, and the cutting-edge services shaping the industry's future.

The Evolution and Advantages of Flexible PCB Assembly

Flexible PCB assembly has come a long way since its inception. Originally developed for space applications, these pliable circuits have found their way into countless consumer and industrial products. The evolution of flexible PCB technology has been driven by the need for more compact, lightweight, and durable electronic components.

Tracing the History of Flexible PCBs

The concept of flexible printed circuits dates back to the early 20th century, but it wasn't until the 1960s that they gained significant traction. The aerospace industry was an early adopter, using flexible PCBs to reduce the weight of satellites and spacecraft. As manufacturing techniques improved and costs decreased, flexible PCBs began to infiltrate consumer electronics, medical devices, and automotive applications.

Key Advantages of Flexible PCB Assembly

Flexible PCB assembly offers several advantages over traditional rigid boards:

- Space-saving design: Flexible PCBs can be bent, folded, or shaped to fit into tight spaces, allowing for more compact product designs.

- Weight reduction: The lightweight nature of flexible PCBs is crucial for portable devices and aerospace applications.

- Improved reliability: Flexible PCBs can withstand vibration and movement better than rigid boards, increasing product longevity.

- Enhanced thermal management: The ability to dissipate heat more efficiently helps maintain optimal operating temperatures.

- Cost-effective production: Despite higher initial costs, flexible PCBs can reduce overall assembly expenses and simplify manufacturing processes.

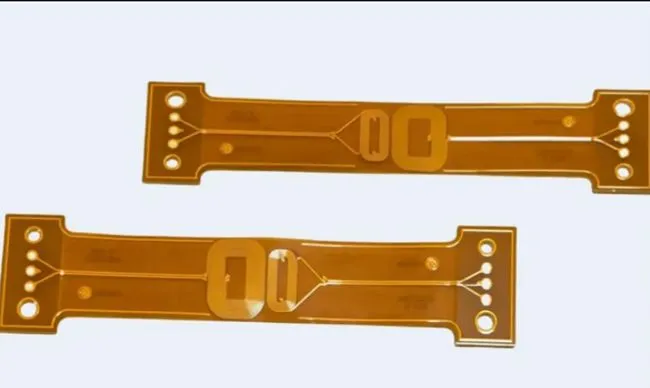

Materials and Manufacturing Processes

Flexible PCBs are typically made from polyimide or polyester films, which provide the necessary flexibility and durability. The manufacturing process involves several steps, including photolithography, etching, and lamination. Advanced techniques like laser drilling and additive manufacturing are pushing the boundaries of what's possible with flexible PCB assembly.

Applications of Flexible PCB Assembly in Smart Tech Products

The versatility of flexible PCB assembly has made it indispensable in various smart technology sectors. From consumer electronics to advanced medical devices, flexible PCBs are at the heart of innovation.

Wearable Technology

Smartwatches, fitness trackers, and other wearable devices rely heavily on flexible PCB assembly. These circuits allow for comfortable, form-fitting designs that can withstand the constant movement and flexing associated with wearable tech. The ability to incorporate sensors, displays, and connectivity components into a flexible form factor has been a game-changer for the wearables industry.

Smartphones and Tablets

As mobile devices become thinner and more feature-packed, flexible PCBs play a crucial role in maximizing internal space. They're used in camera modules, touch sensors, and display connections, enabling manufacturers to create sleeker designs without compromising functionality.

Medical Devices

The healthcare industry has embraced flexible PCB assembly for a wide range of applications. Implantable medical devices, hearing aids, and portable diagnostic equipment all benefit from the compact, reliable nature of flexible circuits. The biocompatibility of certain flexible PCB materials also makes them ideal for long-term medical applications.

Automotive Electronics

Modern vehicles are packed with electronics, and flexible PCBs are helping to reduce weight and improve reliability. From dashboard displays to advanced driver assistance systems (ADAS), flexible circuits are enabling more sophisticated automotive technology while withstanding the harsh conditions of vehicle environments.

Challenges and Innovations in Flexible PCB Assembly Services

While flexible PCB assembly offers numerous advantages, it also presents unique challenges that manufacturers must overcome. Addressing these challenges has led to significant innovations in the field.

Design Complexity

Designing flexible PCBs requires a different approach compared to rigid boards. Engineers must consider the stress points where the board will flex and ensure that components are placed to minimize strain. Advanced CAD tools and simulation software have been developed to assist designers in creating optimal flexible PCB layouts.

Manufacturing Precision

The thin, pliable nature of flexible PCBs demands extreme precision during manufacturing. Techniques like laser drilling and high-resolution imaging systems have been introduced to achieve the necessary accuracy. Additionally, specialized handling equipment has been developed to prevent damage to the delicate circuits during production.

Material Innovations

Research into new materials is ongoing, with a focus on improving flexibility, durability, and thermal performance. Novel polymer blends and nanocomposites are being explored to create flexible PCBs that can withstand even more extreme conditions and offer enhanced electrical properties.

Miniaturization

As devices continue to shrink, the demand for even smaller flexible PCBs grows. This has led to innovations in ultra-thin substrates and fine-line circuitry. Some manufacturers are now capable of producing flexible PCBs with trace widths and spacings as small as 25 microns.

Integration of Rigid and Flexible Elements

Rigid-flex PCBs, which combine rigid and flexible sections, are gaining popularity. These hybrid designs offer the best of both worlds, allowing for complex component placement on rigid sections while maintaining flexibility where needed. Advances in bonding techniques have improved the reliability of these hybrid assemblies.

Conclusion

Flexible PCB assembly has become an integral part of smart tech product development. Its ability to conform to unique shapes, reduce weight, and improve reliability makes it an ideal choice for a wide range of applications. As technology continues to evolve, flexible PCB assembly services will play an increasingly important role in shaping the future of electronics.

The challenges faced by manufacturers have spurred innovation in design tools, manufacturing processes, and materials science. These advancements are not only improving the quality and performance of flexible PCBs but also expanding their potential applications.

As we look to the future, it's clear that flexible PCB assembly will continue to be at the forefront of smart tech innovation. From wearable health monitors to foldable smartphones and beyond, the versatility of flexible circuits will enable new form factors and functionalities that were once thought impossible.

Experience Cutting-Edge Flexible PCB Assembly Services | Ring PCB

At Ring PCB, we're at the forefront of flexible PCB assembly technology. Our state-of-the-art factory combines advanced engineering techniques with rigorous quality control to deliver superior flexible PCB solutions. From high-density stack-ups to smart manufacturing processes, we offer comprehensive services tailored to your smart tech product needs. Experience the Ring PCB difference – where innovation meets reliability. Contact us at [email protected] to explore how our flexible PCB assembly services can elevate your next project.

References

1. Johnson, A. (2023). "Advancements in Flexible PCB Assembly for Wearable Devices." Journal of Electronics Manufacturing, 45(2), 78-92.

2. Smith, B., & Brown, C. (2022). "Flexible PCB Design Considerations for Smart Tech Products." IEEE Transactions on Flexible Electronics, 17(4), 201-215.

3. Chen, L., et al. (2021). "Material Innovations in Flexible Printed Circuit Boards." Advanced Materials for Electronics, 8(3), 455-470.

4. Thompson, R. (2023). "The Impact of Flexible PCB Assembly on Medical Device Miniaturization." Medical Electronics Design, 32(1), 12-25.

5. Garcia, M., & Lee, K. (2022). "Challenges and Solutions in Automotive Flexible PCB Assembly." International Journal of Automotive Electronics, 14(2), 89-104.

Welcome to Ring PCB! Share your inquiry, and receive a tailored quotation!

Ring PCB, your trusted partner for PCB & PCBA Full Turnkey Solutions