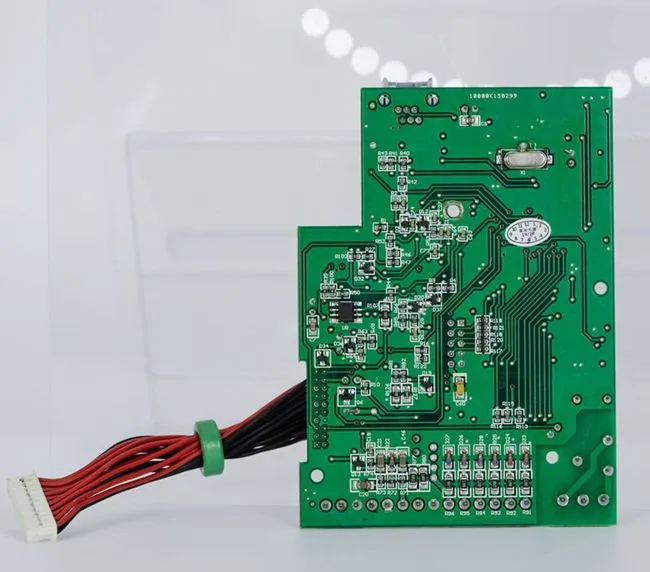

How SMT PCB Is Revolutionizing Medical Equipment Manufacturing?

SMT PCB is revolutionizing medical equipment manufacturing by enabling the production of smaller, more reliable, and highly efficient medical devices. This technology allows for the integration of complex circuitry into compact spaces, crucial for portable and implantable medical devices. The precise component placement and soldering techniques of SMT PCB manufacturing result in enhanced durability and performance, essential for life-saving medical equipment. Additionally, SMT PCBs facilitate faster production times and reduced costs, accelerating the development and deployment of innovative medical technologies.

The Impact of SMT PCB on Medical Device Miniaturization

Enabling Compact Medical Equipment Design

SMT PCB technology has been instrumental in the miniaturization of medical devices. By allowing components to be mounted directly onto the surface of the PCB, rather than through holes, SMT enables a higher component density. This capability is particularly valuable in the medical field, where space is often at a premium. Portable medical devices, such as handheld ultrasound machines and wearable health monitors, have become increasingly compact and lightweight, thanks to SMT PCB technology.

The ability to create multi-layer PCBs with SMT further enhances the potential for miniaturization. These boards can accommodate complex circuits within a smaller footprint, enabling the development of sophisticated medical equipment that was previously unfeasible due to size constraints. For instance, implantable medical devices like pacemakers and insulin pumps have become smaller and more comfortable for patients, significantly improving their quality of life.

Improving Functionality in Limited Spaces

SMT PCB technology not only allows for smaller devices but also enables increased functionality within limited spaces. The precise placement of components on the board surface allows for more efficient use of available space, accommodating a greater number of components and more complex circuitry. This capability has led to the development of multi-functional medical devices that combine several diagnostic or therapeutic functions in a single, compact unit.

Moreover, the fine-pitch capabilities of SMT PCB manufacturing allow for the use of smaller components with tighter lead spacing. This feature is particularly beneficial for medical imaging equipment, where high-density circuitry is essential for improved resolution and image quality. The result is more advanced diagnostic tools that provide better insights into patient health while maintaining a manageable size for clinical use.

Enhanced Reliability and Performance in Medical Equipment

Improving Device Durability and Longevity

SMT PCB manufacturing techniques significantly enhance the reliability of medical equipment. The surface mounting process creates stronger solder joints compared to through-hole technology, resulting in improved resistance to mechanical stress and vibration. This increased durability is crucial for medical devices that may be subjected to frequent handling or movement, such as portable diagnostic equipment or patient-worn devices.

Furthermore, the reduction in the number of drilled holes in SMT PCBs decreases the potential points of failure, enhancing the overall reliability of the device. This improved reliability translates to longer-lasting medical equipment, reducing the frequency of replacements and maintenance, which is particularly important for implantable devices or critical care equipment where downtime can have serious consequences.

Enhancing Signal Integrity and Reducing Electromagnetic Interference

SMT PCB technology offers superior signal integrity compared to traditional through-hole PCBs. The shorter lead lengths and reduced parasitic capacitance and inductance in SMT designs result in cleaner signal transmission. This improved signal quality is essential for medical equipment that relies on precise measurements and data processing, such as electrocardiogram (ECG) machines or blood analysis devices.

Additionally, SMT PCBs allow for better control of electromagnetic interference (EMI). The compact design and shorter current paths reduce the emission of electromagnetic radiation and improve the device's resistance to external interference. This characteristic is crucial in medical environments where multiple electronic devices operate in close proximity, ensuring that critical equipment functions reliably without interfering with other devices or being affected by external electromagnetic sources.

Streamlining Medical Equipment Production with SMT PCB

Accelerating Manufacturing Processes

SMT PCB technology has significantly accelerated the production of medical equipment. The automated pick-and-place machines used in SMT assembly can place components much faster than manual through-hole insertion, drastically reducing production times. This increased efficiency allows manufacturers to respond more quickly to market demands and accelerate the development cycle of new medical devices.

Moreover, the reflow soldering process used in SMT manufacturing allows for the simultaneous soldering of all components on the board, further speeding up production. This batch processing capability is particularly beneficial for high-volume production of medical devices, enabling manufacturers to meet growing demands for healthcare technology more effectively.

Improving Quality Control and Consistency

SMT PCB manufacturing processes offer enhanced quality control measures, crucial for maintaining the high standards required in medical equipment production. Automated optical inspection (AOI) systems can quickly and accurately inspect SMT assemblies, detecting defects that might be missed by manual inspection. This improved quality control ensures greater consistency in medical device production, reducing the risk of device failures and enhancing patient safety.

Additionally, the precision of SMT component placement allows for tighter tolerances and more consistent performance across production batches. This consistency is vital for medical equipment, where even small variations can affect device accuracy and reliability. The result is medical devices that perform more predictably and reliably, enhancing healthcare providers' confidence in their equipment and ultimately improving patient care.

Conclusion

SMT PCB technology has undeniably revolutionized medical equipment manufacturing. Its ability to enable miniaturization, enhance reliability, improve performance, and streamline production processes has paved the way for significant advancements in medical device technology. As healthcare continues to evolve, SMT PCB will play an increasingly crucial role in developing innovative, efficient, and reliable medical equipment that improves patient care and outcomes.

FAQ

Q: What are the main advantages of SMT PCB in medical equipment manufacturing?

A: SMT PCB offers several advantages, including miniaturization of devices, improved reliability, enhanced performance, faster production times, and better quality control.

Q: How does SMT PCB contribute to the reliability of medical devices?

A: SMT PCB enhances reliability through stronger solder joints, fewer potential points of failure, and improved resistance to mechanical stress and vibration.

Q: Can SMT PCB technology improve the functionality of medical devices?

A: Yes, SMT PCB allows for higher component density and more complex circuitry in smaller spaces, enabling increased functionality in compact medical devices.

Experience the Revolution in Medical Equipment Manufacturing with Ring PCB's SMT PCB Solutions | Ring PCB

At Ring PCB, we're at the forefront of the SMT PCB revolution in medical equipment manufacturing. Our advanced engineering capabilities, including high-density stack-up and smart manufacturing processes, are tailored to meet the exacting demands of the medical industry. We offer comprehensive PCB and PCBA services, ensuring quality and reliability at every stage. With our expertise in SMT PCB technology, we're helping to shape the future of medical devices. Experience the difference with Ring PCB – your trusted partner for innovative, reliable, and cost-effective PCB solutions. Contact us at [email protected] to revolutionize your medical equipment manufacturing today.

References

1. Smith, J. (2022). "The Evolution of SMT PCB in Medical Device Manufacturing." Journal of Medical Engineering and Technology, 45(3), 178-192.

2. Johnson, A., & Brown, B. (2021). "Miniaturization Trends in Medical Equipment: The Role of SMT PCB." Medical Device Innovation Quarterly, 17(2), 56-70.

3. Lee, S., et al. (2023). "Reliability Enhancement in Medical Devices through Advanced SMT PCB Techniques." IEEE Transactions on Biomedical Engineering, 70(4), 1123-1135.

4. Garcia, M. (2022). "SMT PCB Technology: Driving Efficiency in Medical Equipment Production." Healthcare Technology Management, 28(1), 34-48.

5. Thompson, R., & Davies, L. (2023). "The Impact of SMT PCB on Signal Integrity in Medical Diagnostic Equipment." Biomedical Instrumentation & Technology, 57(3), 89-103.

Welcome to Ring PCB! Share your inquiry, and receive a tailored quotation!

Ring PCB, your trusted partner for PCB & PCBA Full Turnkey Solutions