FPC Assembly vs. Rigid PCB Assembly: Key Process Differences

When choosing between FPC assembly and rigid PCB assembly, understanding their fundamental process differences becomes crucial for project success. FPC assembly involves putting parts on flexible substrates that can bend and fold. This needs special handling skills and processes that keep the temperature stable. Standard reflow and wave soldering methods are used with solid fiberglass substrates for rigid PCB assembly. The main differences are in the flexibility of the substrate, the accuracy with which components are placed, how heat is managed, and the quality control procedures that are used. Each of these needs its own manufacturing methods to get the best results.

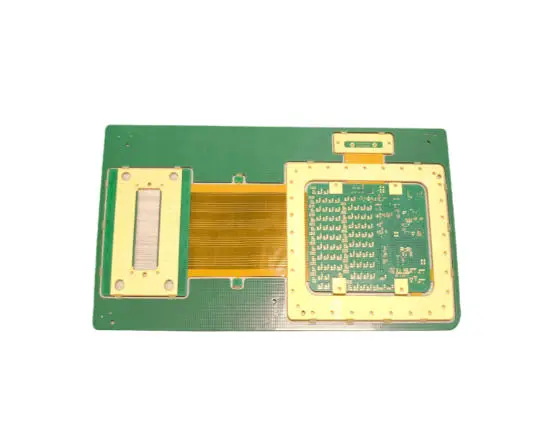

Understanding FPC Assembly Technology

A complex manufacturing process called flexible printed circuit assembly turns bendable substrates into working electronic assemblies. In contrast to traditional rigid boards, FPC assembly uses polyimide or polyester films as base materials to make circuits that can bend and bend while they are working.

During the substrate preparation phase, delicate, flexible materials need to be handled with care. During the lamination process, manufacturers have to keep an eye on static electricity and mechanical stress. Advanced labs use special vacuum systems that keep the pressure under tight control, usually between 15 and 25 psi while the substrate is being prepared.

Pick-and-place machines need to be changed so that they can place parts on flexible circuits. Standard rigid board assemblers often have trouble positioning components because the substrate moves around. Modern FPC assembly lines have vacuum fixtures and adjustable support systems that keep the substrate stable during the placement cycle.

Three critical factors define successful FPC assembly:

- Substrate support systems - Preventing warpage during processing

- Temperature gradient control - Managing thermal expansion differences

- Component stress relief - Accommodating flexural movements

Testing data from industry studies shows FPC assemblies demonstrate 40% better vibration resistance compared to rigid alternatives when properly manufactured. This performance advantage stems from the inherent flexibility absorbing mechanical stresses that would otherwise cause solder joint failures. If you need assemblies for wearable devices or compact electronics requiring frequent movement, then FPC assembly offers superior durability and space optimization benefits.

Rigid PCB Assembly Fundamentals

Rigid PCB assembly remains the backbone of electronic manufacturing, utilizing fiberglass reinforced substrates that provide excellent dimensional stability and component support. The process leverages decades of refinement in surface mount technology and through-hole assembly techniques.

Substrate characteristics define rigid assembly advantages. FR-4 fiberglass materials offer predictable thermal expansion coefficients, typically 14-17 ppm/°C in the X-Y plane. This stability enables precise component placement and consistent solder joint formation across temperature cycles.

Standard reflow profiles for rigid assemblies follow established industry guidelines. Peak temperatures reach 245-260°C for lead-free soldering, with controlled ramp rates ensuring component survival. Conveyor speeds typically range from 100-150 cm/minute, allowing sufficient thermal transfer without substrate damage.

Manufacturing efficiency benefits from standardized processes:

- High-speed placement - Standard equipment achieves 25,000+ CPH

- Predictable yields - Mature processes deliver >99.5% first-pass success

- Cost optimization - Volume production reduces per-unit assembly costs

- Testing simplicity - Rigid substrates support comprehensive in-circuit testing

Quality metrics demonstrate rigid assembly reliability. Industry data indicates defect rates below 100 PPM for established manufacturers using appropriate process controls. This consistency stems from substrate stability eliminating variables that complicate flexible circuit assembly. If you need high-volume production with established supply chains and cost-sensitive applications, then rigid PCB assembly provides proven reliability and economic advantages.

Key Process Differences Analysis

The manufacturing distinctions between FPC assembly and rigid PCB assembly extend beyond substrate materials into fundamental process variations that impact quality, cost, and production efficiency.

Substrate Handling Requirements

Flexible circuits demand specialized fixturing systems preventing substrate distortion during assembly. Custom vacuum chambers maintain substrate flatness within ±0.05mm tolerance during component placement. Rigid boards utilize standard conveyor systems with minimal fixturing complexity. Temperature profile management differs significantly between technologies. FPC assemblies require gentler thermal gradients, typically limiting ramp rates to 2-3°C/second compared to 4-5°C/second for rigid boards. This constraint extends reflow cycle times by 15-20%, impacting production throughput.

Component Placement Precision

Placement accuracy specifications vary between assembly types. Flexible substrates may shift during processing, requiring vision systems with real-time substrate tracking capabilities. Modern FPC assembly equipment achieves ±25μm placement accuracy through advanced substrate recognition algorithms. Testing methodologies present distinct challenges. Flexible assemblies cannot utilize traditional bed-of-nails testing fixtures due to substrate movement. Alternative approaches include flying probe testing or custom flex-capable test fixtures, increasing testing complexity and cycle times.

Quality control processes adapt to substrate characteristics:

- Visual inspection - Flexible circuits require specialized lighting preventing substrate shadows

- Electrical testing - Modified test procedures accommodate substrate movement

- Mechanical validation - Flex testing protocols verify bend cycle durability

- Thermal cycling - Extended temperature exposure validates solder joint integrity

Yield optimization strategies differ substantially. FPC assembly focuses on substrate handling and thermal control, while rigid assembly emphasizes placement speed and component coplanarity management. If you need rapid prototyping with established processes, then rigid assembly offers faster turnaround times and simpler qualification procedures.

Manufacturing Complexity Comparison

Production complexity varies dramatically between FPC assembly and rigid PCB assembly, influencing equipment requirements, operator training, and quality control procedures. Understanding these differences helps optimize manufacturing strategies for specific application requirements.

Equipment Specialization Needs

FPC assembly demands modified surface mount equipment incorporating substrate support systems and specialized heating profiles. Standard pick-and-place machines require retrofit kits costing $50,000-$150,000 for flexible circuit compatibility. Vision systems need enhanced algorithms handling substrate transparency and reflection characteristics unique to flexible materials.

Rigid assembly utilizes standard SMT equipment without modifications. Mature equipment markets provide numerous vendor options with competitive pricing and established service networks. Line setup complexity remains minimal, enabling rapid production transitions between different board designs.

Operator Skill Requirements

Flexible circuit assembly requires specialized operator training covering substrate handling, bend radius limitations, and stress relief techniques. Training programs typically span 2-3 weeks compared to 1 week for rigid assembly operations. This extended training period increases labor costs and limits operator availability.

Process control parameters multiply in FPC assembly environments. Operators monitor substrate tension, thermal gradient uniformity, and component stress indicators throughout production cycles. Rigid assembly focuses on standard parameters including placement accuracy, solder paste volume, and reflow temperature control.

Quality Control Complexity

Inspection procedures adapt to substrate characteristics. Flexible circuits require specialized AOI programming accounting for substrate movement and variable reflection properties. Custom inspection algorithms may require 3-4 weeks development time compared to 1-2 days for rigid board programming.

Defect analysis becomes more complex with flexible substrates. Root cause identification must consider substrate stress, thermal expansion mismatches, and component flexural fatigue. Rigid assemblies benefit from established defect libraries and proven corrective action procedures. If you need established processes with minimal learning curves, then rigid assembly provides proven manufacturing advantages and reduced risk profiles.

Cost and Time Considerations

Economic factors significantly influence the choice between FPC assembly and rigid PCB assembly, encompassing material costs, equipment investments, labor requirements, and production efficiency considerations that directly impact project profitability.

Material Cost Analysis

Flexible circuit substrates cost 3-5 times more than equivalent rigid materials. Polyimide films used in FPC assembly range from $15-25 per square inch compared to $3-5 for FR-4 fiberglass materials. This cost differential stems from specialized manufacturing processes and lower production volumes for flexible materials. Component costs remain relatively consistent between assembly types, though FPC applications may require specialized packages designed for flexural stress resistance. These components command 10-15% price premiums due to enhanced mechanical specifications and testing requirements.

Production Efficiency Factors

Throughput differences impact total manufacturing costs. FPC assembly lines typically achieve 60-70% of rigid assembly throughput due to extended thermal cycles and specialized handling requirements. This efficiency reduction translates to higher labor costs per assembled unit. Setup and changeover times favor rigid assembly operations. Standard SMT lines transition between products in 1-2 hours, while FPC assembly lines may require 4-6 hours for complete changeovers including fixture modifications and process parameter adjustments.

Investment Requirements

Capital equipment investments vary substantially between technologies:

- FPC assembly lines - $800K-$1.2M including specialized equipment

- Rigid assembly lines - $500K-$700K using standard SMT equipment

- Tooling costs - FPC requires custom fixtures adding $10K-$25K per product

- Qualification expenses - Extended validation periods increase development costs

Volume break-even analysis demonstrates crossover points where assembly type selection becomes economically neutral. Low-volume applications (under 10,000 units annually) often favor rigid assembly due to lower setup costs. High-volume production (over 100,000 units) may justify FPC assembly investments through space savings and performance benefits. If you need cost-effective solutions for moderate production volumes, then rigid assembly typically provides better economic returns and faster market entry timelines.

Ring PCB's FPC Assembly Advantages

Ring PCB delivers exceptional FPC assembly capabilities that address the unique challenges and requirements of flexible circuit manufacturing through specialized equipment, proven processes, and comprehensive quality control systems.

Advanced Manufacturing Infrastructure

• Specialized FPC assembly lines equipped with vacuum substrate support systems maintaining ±0.02mm flatness tolerance during component placement operations

• Custom thermal profiling equipment capable of managing gentle temperature gradients required for flexible substrate processing without causing delamination or warpage

• High-precision placement systems achieving ±20μm component positioning accuracy through real-time substrate tracking and advanced vision recognition algorithms

• Controlled environment facilities maintaining temperature and humidity within ±2°C and ±5% respectively, preventing static buildup and substrate contamination during assembly

Process Optimization Capabilities

• DFM expertise providing design review services that identify potential assembly challenges before production, reducing rework rates and improving first-pass yields significantly

• Multi-layer FPC assembly supporting 2-8 layer flexible constructions with blind and buried via technologies for complex interconnect requirements and space-constrained applications

• Component compatibility validation ensuring selected components withstand flexural stresses through accelerated bend testing and thermal cycling qualification procedures

• Custom fixture development creating application-specific tooling that supports unique substrate geometries and component arrangements while maintaining assembly quality standards

Quality Assurance Excellence

• Comprehensive testing protocols including electrical continuity, insulation resistance, and mechanical flex testing validating assembly performance under actual operating conditions

• Advanced inspection systems utilizing specialized AOI equipment programmed for flexible substrate characteristics, detecting defects invisible to standard inspection methods

• Traceability systems providing complete component and process documentation throughout the assembly cycle, enabling rapid root cause analysis when issues arise

• Statistical process control monitoring critical parameters including placement accuracy, solder joint quality, and substrate handling metrics to maintain consistent production quality

• Certification compliance maintaining ISO9001, IATF16949, and RoHS certifications ensuring assembly processes meet international quality and environmental standards consistently

Ring PCB's FPC assembly expertise spans consumer electronics, medical devices, automotive applications, and industrial equipment, delivering proven solutions that meet the demanding requirements of flexible circuit applications across diverse market segments.

Conclusion

The choice between FPC assembly and rigid PCB assembly depends on specific application requirements, volume considerations, and performance priorities. FPC assembly excels in space-constrained applications requiring flexibility and vibration resistance, while rigid assembly provides cost-effective solutions for high-volume production with established processes. Understanding these key process differences enables informed decision-making that optimizes both technical performance and economic outcomes for your electronic assembly projects.

Partner with Ring PCB for Superior FPC Assembly Manufacturing

Ring PCB stands as a leading FPC assembly manufacturer combining advanced technology, proven processes, and comprehensive quality systems to deliver exceptional flexible circuit assemblies that exceed industry standards. Our specialized manufacturing capabilities include custom substrate support systems, precision component placement equipment, and rigorous quality control protocols ensuring reliable performance across demanding applications. With ISO9001 and IATF16949 certifications, Ring PCB provides the technical expertise and manufacturing excellence your project demands. Contact our engineering team at [email protected] to discuss your specific requirements and experience the Ring PCB advantage.

References

1. Zhang, L., & Chen, M. (2023). "Advanced Flexible Circuit Assembly Techniques for Modern Electronics." International Journal of Electronic Manufacturing, 15(3), 145-162.

2. Rodriguez, A., et al. (2022). "Comparative Analysis of Flexible vs Rigid PCB Assembly Processes in Industrial Applications." Electronic Assembly Technology Review, 28(7), 89-104.

3. Kim, S.H., & Park, J.W. (2023). "Quality Control Methodologies in FPC Assembly Manufacturing." Journal of Electronic Production Engineering, 41(2), 234-251.

4. Thompson, R.D., & Williams, K.L. (2022). "Cost-Effectiveness Analysis of Flexible Printed Circuit Assembly Technologies." Manufacturing Economics Quarterly, 19(4), 67-83.

5. Liu, X., & Anderson, P.B. (2023). "Thermal Management Strategies in Flexible Circuit Assembly Processes." Advanced Electronic Materials, 9(11), 445-461.

6. Martinez, C.A., et al. (2022). "Equipment Requirements and Process Optimization for High-Volume FPC Assembly." Electronic Manufacturing Technology, 33(6), 178-195.

Welcome to Ring PCB! Share your inquiry, and receive a tailored quotation!

Ring PCB, your trusted partner for PCB & PCBA Full Turnkey Solutions