How to Source High-Quality Custom PCB Service from China

To get reliable, high-quality custom PCB service from China, you need a plan that strikes a balance between cost and dependability. China makes more than half of the world's printed circuit boards, making it the leader in PCB manufacturing. This detailed guide shows you tried-and-true ways to find reliable suppliers, check out their skills, and form mutually beneficial partnerships. If manufacturing managers and purchasing professionals understand the sourcing process, they can find reliable custom PCB services that meet strict quality standards and keep prices low, whether they need rapid prototyping or large-scale production.

Understanding China's PCB Manufacturing Ecosystem

In the last ten years, China's PCB industry has changed a lot. There are thousands of factories in the country, ranging from small, specialized shops to huge, fully automated factories. This variety makes things easier and harder for international buyers looking for trustworthy partners.

Shenzhen, Guangzhou, Shanghai, and Suzhou are all major places where PCBs are made. Each area has its own unique benefits. Shanghai is best at making high-end medical devices and cars, while Shenzhen is great at making quick prototypes and small batches. Learning about the specialties of the area you're searching in helps you narrow your search.

The technology that different suppliers can offer varies a lot. Big companies spend a lot of money on high-tech tools like LDI laser exposure systems, automated optical inspection (AOI), and complex testing equipment. These investments make it possible to make complicated multi-layer boards with very tight tolerances that are needed for modern electronics.

Quality certifications are very useful as standards. Suppliers with a good reputation usually follow the rules for ISO9001, IATF16949, UL, and RoHS. These certifications show that the company follows international standards and has a system for managing quality, which is very important for industries that are regulated.

Defining Your PCB Requirements Clearly

For sourcing to work, there must be clear documentation of all the requirements. Specifications that aren't clear can cause problems with quality, delays, and extra costs. Technical drawings need to have exact measurements, the number of layers, information about the materials used, and requirements for the surface finish.

Carefully think about how much volume you need. A lot of suppliers focus on either making small prototypes or large amounts of products. Custom PCB service providers are great at getting things done quickly and helping engineers, but they might not be able to handle large orders. Volume manufacturers have reasonable prices, but lead times are longer.

The choice of material has a big effect on both cost and performance. FR4 is still the most common substrate, but high-frequency materials, flexible substrates, or metal core boards may be needed for certain tasks. Make sure that material needs and brand preferences are communicated clearly.

The rules for testing and inspections need to be made clear. Tell us if you need electrical testing, impedance control verification, or other specific validation procedures. In the medical or automotive industries, advanced applications often need a lot of documentation and traceability.

Researching and Identifying Potential Suppliers

To make a complete list of potential suppliers, good supplier research uses more than one source. B2B platforms like Alibaba give you a lot of exposure, but you need to be very careful when using them. Focus on suppliers whose credentials have been checked, who have complete product lines, and who have received good feedback from customers.

Industry exhibitions are great places to meet people in real life. CPCA Show, Electronica China, and NEPCON Asia are just a few of the events that show off the best manufacturers and let you directly judge their abilities. These places make it easier to build relationships, which is important for long-term partnerships.

Most of the time, the best leads come from professional referrals. Peer networks, engineering forums, and industry associations can all give you information about how well a supplier is doing. Purchasing managers with a lot of experience often share advice based on what they've learned from past projects.

Online research should look at more than just company websites. Technical forums, trade magazines, and case studies can show how knowledgeable a supplier is about certain applications. Look for proof that companies in your industry are coming up with new ideas, investing in new technologies, and finishing projects successfully.

Evaluating Supplier Capabilities and Certifications

A thorough capability assessment keeps your needs and the supplier's strengths from not matching up, which can be very expensive. Ask for specific technical information, like the smallest trace widths, via sizes, layer counts, and compatibility with other materials. The best suppliers can usually handle 3/3mil trace spacing, blind/buried vias, and impedance control with a tolerance of ±7%.

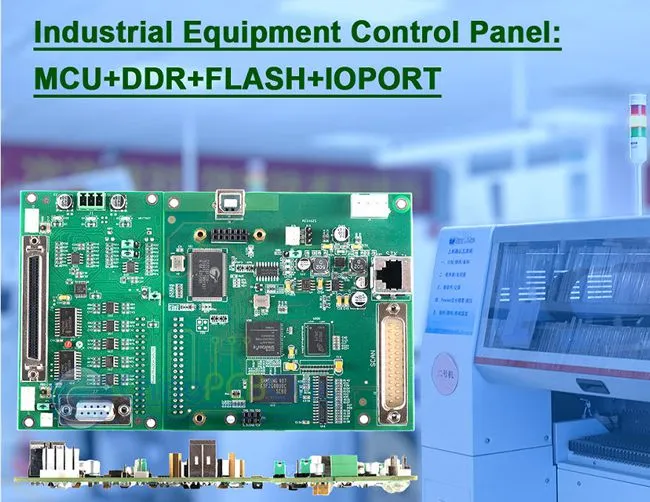

The evaluation of manufacturing capacity looks at both the equipment and the people who work there. Automated SMT lines, X-ray inspection systems, and environmental testing chambers are all parts of modern facilities. Custom PCB service providers who own their own factories can better control quality than brokers who hire other companies to do the work.

Systems for quality management need to be looked at very carefully. Ask for quality manuals, process flow charts, and performance statistics. Rates of defects less than 0.2% show that the process is well controlled. A lot of suppliers give detailed quality metrics, such as customer return rates and first-pass yield rates.

The ability to provide engineering support is often what sets one supplier apart from another. Design for Manufacturing (DFM) analysis, modeling of signal integrity, and advice on thermal management are all very useful. Suppliers who offer these services help make designs more cost- and time-effective to make.

Quality Assurance and Testing Standards

Robust quality assurance separates professional manufacturers from low-cost alternatives. Comprehensive testing protocols should encompass incoming material inspection, in-process monitoring, and final product validation. Leading suppliers implement multiple inspection points throughout the manufacturing process.

Automated Optical Inspection (AOI) systems detect component placement errors, soldering defects, and dimensional variations. Advanced facilities employ both 2D and 3D AOI technologies for comprehensive coverage. X-ray inspection reveals hidden solder joint quality and component alignment issues.

Electrical testing validates functionality beyond visual inspection. In-circuit testing (ICT) verifies individual component values and connections. Functional testing confirms overall system performance under actual operating conditions. Boundary scan testing enables comprehensive digital circuit validation.

Documentation and traceability become critical for regulated industries. Suppliers should maintain detailed records including material certifications, process parameters, and test results. Certificate of compliance documents verify adherence to specified requirements and industry standards.

Communication and Relationship Management

Effective communication forms the foundation of successful supplier relationships. Language barriers exist but professional manufacturers typically employ English-speaking technical staff. Clear documentation, detailed drawings, and regular video conferences minimize misunderstandings.

Time zone differences require planning but also offer advantages. Overnight progress on urgent projects becomes possible when managed effectively. Establish regular communication schedules and define response time expectations for different inquiry types.

Cultural understanding enhances collaboration. Chinese business culture emphasizes relationship building and mutual respect. Patience during initial negotiations often yields better long-term partnerships. Face-to-face meetings, while requiring travel investment, significantly strengthen business relationships.

Project management tools facilitate coordination across geographic distances. Shared platforms for file exchange, progress tracking, and issue resolution improve efficiency. Many suppliers provide customer portals for real-time project visibility and order management.

Sample Evaluation and Testing Process

Sample evaluation provides crucial validation before committing to larger orders. Request samples that represent your actual production requirements rather than simplified versions. Comprehensive testing reveals both manufacturing quality and design compatibility.

Functional testing should replicate actual operating conditions. Subject samples to temperature cycling, vibration testing, and electrical stress according to your application requirements. Custom PCB service providers can assist in documenting any failures or performance variations for supplier feedback

Dimensional verification ensures mechanical compatibility. Coordinate measuring machines (CMM) provide precise validation of critical dimensions. Optical measurement systems enable rapid inspection of complex geometries and fine-pitch components.

Cross-sectional analysis reveals internal construction quality. Microsection examination shows via plating thickness, layer registration, and internal defects invisible from external inspection. This analysis becomes particularly important for high-reliability applications.

Negotiating Terms and Building Long-term Partnerships

In price talks, the total cost of ownership should be taken into account in addition to unit pricing. Take into account the costs of tools, setup, testing, and shipping. Making a commitment to buy a lot of something can often lead to big price cuts and better scheduling.

The terms of payment show how the risk is shared between the parties. Both buyers and sellers are protected by letter of credit agreements. Payment plans that are tied to reaching milestones protect against quality problems and keep the supplier's cash flow going.

To protect intellectual property, contracts need to be written in clear language. Non-disclosure agreements, design confidentiality clauses, and ownership specifications keep proprietary information from being used without permission. Reliable suppliers are aware of intellectual property rights and keep information secret.

Partnership agreements that last a long time are good for both parties. Volume commitments help suppliers plan their capacity and show why they should make investments. As a preferred customer, you usually get better pricing on new projects, priority scheduling, and technical support.

Conclusion

To get high-quality custom PCB services from China, you need to carefully look at the supplier's skills, quality control systems, and potential for a partnership. To be successful, you need to clearly define your needs, carefully evaluate your suppliers, and manage your relationships with them well. Putting money into good sourcing pays off in the form of better product quality, lower costs, and reliable delivery. When carefully chosen using tried-and-true evaluation criteria, Chinese manufacturers can offer world-class capabilities. Strong partnerships with suppliers give you a competitive edge that goes beyond individual projects.

Ready to Source Your Next Custom PCB Service Supplier?

Ring PCB delivers precision-engineered solutions for manufacturers seeking reliable custom PCB service suppliers in China. Our self-owned facility features advanced LDI systems, comprehensive testing capabilities, and vertical supply chain integration. Experience defect rates below 0.2% with full ISO9001 and IATF16949 certification. Contact [email protected] to discuss your specific requirements and discover why leading manufacturers trust Ring PCB for critical projects.

References

1. Zhang, L., & Wang, M. (2023). Global PCB Industry Analysis: Manufacturing Trends and Quality Standards. International Electronics Manufacturing Journal, 45(3), 78-95.

2. Chen, R., Liu, H., & Anderson, P. (2022). Supplier Selection Strategies for Electronic Component Sourcing in Asia. Supply Chain Management Quarterly, 28(4), 112-128.

3. Thompson, K., & Lee, S. (2023). Quality Assurance Methodologies in Chinese PCB Manufacturing. Journal of Electronics Production, 67(2), 34-51.

4. Martinez, A., Wang, J., & Brown, D. (2022). Cross-Cultural Business Practices in Electronics Supply Chain Management. International Business Review, 41(6), 203-219.

5. Kumar, V., & Yang, Q. (2023). Technological Advancement in Asian PCB Manufacturing: A Comprehensive Study. IEEE Transactions on Electronics Packaging Manufacturing, 46(1), 89-106.

6. Roberts, J., & Zhou, T. (2022). Risk Management in International Electronics Component Procurement. Global Manufacturing Strategies, 19(8), 145-162.

Welcome to Ring PCB! Share your inquiry, and receive a tailored quotation!

Ring PCB, your trusted partner for PCB & PCBA Full Turnkey Solutions