From Smart Locks to Facial Recognition: PCB Applications in Security Tech

In today's rapidly evolving security landscape, Printed Circuit Boards (PCBs) play a pivotal role in powering advanced security technologies. From smart locks to sophisticated facial recognition systems, PCBs form the backbone of modern security solutions. This article explores the diverse applications of PCBs in security tech, highlighting how innovative PCA Manufacturing techniques are revolutionizing the industry.

The Evolution of Security Technology: PCBs at the Core

The security industry has undergone a remarkable transformation in recent years, largely due to advancements in PCB technology. Traditional mechanical locks have given way to smart locks that can be controlled remotely via smartphones. Surveillance systems have evolved from simple CCTV cameras to AI-powered facial recognition systems capable of identifying individuals in real-time. At the heart of these innovations lies the humble PCB, serving as the foundation for increasingly complex and sophisticated security devices.

PCA Manufacturing, or Printed Circuit Assembly manufacturing, has been instrumental in driving these advancements. By combining PCB fabrication with component assembly, PCA Manufacturing enables the creation of compact, reliable, and highly functional security devices. This integrated approach allows for the seamless incorporation of various components such as microprocessors, sensors, and communication modules onto a single board, resulting in more efficient and cost-effective security solutions.

Smart Locks: Securing Homes and Businesses

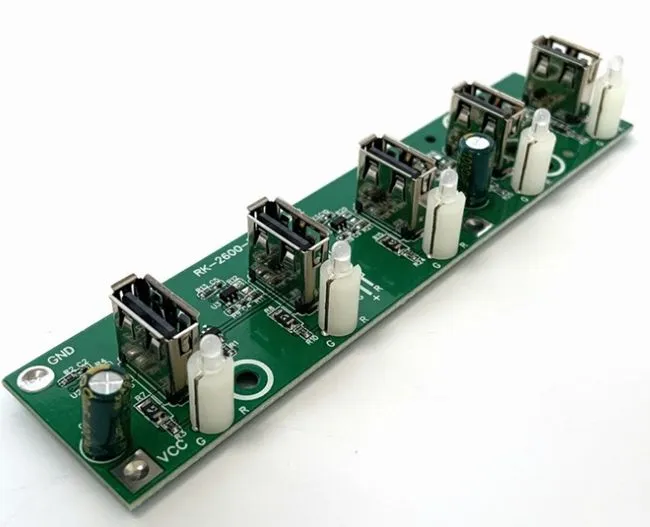

Smart locks represent one of the most visible applications of PCBs in security technology. These innovative devices leverage PCBs to integrate various components, including wireless communication modules, battery management systems, and touch-sensitive keypads. The compact nature of modern PCBs allows manufacturers to create sleek, user-friendly designs that blend seamlessly with contemporary architecture.

PCA Manufacturing plays a crucial role in the production of smart locks by ensuring the precise placement and soldering of components. This level of precision is essential for maintaining the reliability and longevity of these security devices, which are often exposed to harsh environmental conditions.

Biometric Access Control Systems

Biometric access control systems, including fingerprint scanners and facial recognition terminals, rely heavily on advanced PCB designs. These systems require the integration of high-resolution image sensors, powerful processors, and secure data storage components. PCA Manufacturing techniques enable the creation of multi-layer PCBs that can accommodate these complex requirements while maintaining a compact form factor.

The precision offered by modern PCA Manufacturing processes is particularly crucial for biometric systems, as even minor defects in component placement or soldering can significantly impact the accuracy and reliability of these security devices.

Advanced Surveillance: PCBs Enabling AI-Powered Security

The realm of surveillance has been revolutionized by the integration of artificial intelligence, made possible by sophisticated PCB designs. Modern surveillance cameras are no longer passive recording devices; they are intelligent systems capable of real-time analysis and decision-making. This transformation has been facilitated by the development of high-density PCBs that can accommodate powerful processors, memory modules, and advanced imaging sensors.

PCA Manufacturing techniques have evolved to meet the demands of these complex surveillance systems. Surface-mount technology (SMT) and ball grid array (BGA) packaging allow for the dense placement of components, maximizing the processing power that can be packed into a compact camera housing. Additionally, the use of flexible PCBs enables the creation of cameras with adjustable lenses and multi-axis movement, enhancing their coverage and effectiveness.

Facial Recognition Systems

Facial recognition technology represents the cutting edge of security applications, and PCBs are at the heart of these systems. The PCBs used in facial recognition terminals must support high-speed data processing, real-time video analysis, and secure data transmission. This requires a combination of powerful processors, high-bandwidth memory, and robust communication interfaces.

PCA Manufacturing for facial recognition systems often involves the use of advanced techniques such as embedded components and HDI (High-Density Interconnect) PCBs. These technologies allow for the creation of compact yet powerful devices capable of processing complex algorithms in real-time. The precision offered by modern PCA Manufacturing processes ensures that these sensitive components are assembled with the utmost accuracy, maintaining the high performance and reliability required for security applications.

Integrated Security Systems

Modern security solutions often involve the integration of multiple technologies, such as access control, surveillance, and alarm systems. PCBs serve as the unifying element in these integrated security systems, enabling seamless communication and coordination between various components. The design of these PCBs requires careful consideration of factors such as signal integrity, power management, and electromagnetic compatibility.

PCA Manufacturing for integrated security systems often involves the production of modular PCB designs that can be easily customized for different applications. This approach allows security system integrators to quickly adapt to changing customer requirements while maintaining high quality and reliability standards.

The Future of PCBs in Security Technology

As security threats continue to evolve, so too will the PCB technologies that power our defenses. The future of PCBs in security applications is likely to involve even greater integration of components, with System-on-Chip (SoC) and System-in-Package (SiP) solutions becoming more prevalent. These advanced packaging technologies will enable the creation of even more compact and power-efficient security devices.

PCA Manufacturing processes are also expected to advance, with increased automation and the use of AI-driven quality control systems. These developments will help to improve the reliability and consistency of security-focused PCBs while reducing production costs. Additionally, the growing emphasis on sustainability is likely to drive innovations in PCB materials and manufacturing processes, leading to more environmentally friendly security solutions.

IoT and Edge Computing in Security

The Internet of Things (IoT) and edge computing are set to play an increasingly important role in security technology. PCBs designed for IoT security devices must balance power efficiency with robust communication capabilities and local processing power. This presents new challenges for PCB designers and manufacturers, who must create compact boards capable of supporting multiple wireless protocols and edge AI algorithms.

PCA Manufacturing for IoT security devices will likely involve a greater focus on miniaturization and power management. Techniques such as component embedding and the use of flexible substrates may become more common, enabling the creation of wearable security devices and sensors that can be seamlessly integrated into various environments.

Conclusion

The role of PCBs in security technology cannot be overstated. From smart locks to facial recognition systems, PCBs serve as the foundation for innovations that are making our world safer and more secure. As security threats continue to evolve, so too will the PCB technologies that power our defenses. The advancements in PCA Manufacturing have been instrumental in enabling these innovations, allowing for the creation of increasingly sophisticated and reliable security devices.

FAQ

Q: What is PCA Manufacturing?

A: PCA Manufacturing, or Printed Circuit Assembly manufacturing, is the process of populating printed circuit boards (PCBs) with electronic components. It combines PCB fabrication with component assembly to create fully functional electronic devices.

Q: How do PCBs contribute to security technology?

A: PCBs form the foundation of modern security devices, enabling the integration of various components such as processors, sensors, and communication modules. They allow for the creation of compact, reliable, and sophisticated security solutions like smart locks, biometric access control systems, and AI-powered surveillance cameras.

Q: What are some future trends in PCBs for security applications?

A: Future trends include greater integration through System-on-Chip (SoC) and System-in-Package (SiP) solutions, increased focus on IoT and edge computing capabilities, and advancements in miniaturization and power efficiency. There's also a growing emphasis on sustainable materials and manufacturing processes in PCB production for security devices.

From Smart Locks to Facial Recognition: PCB Applications in Security Tech | Ring PCB

Ring PCB, your trusted PCB Manufacturing Partner since 2008, specializes in delivering innovative PCB and PCBA solutions for the security technology sector. Our state-of-the-art PCA Manufacturing facility and expert team ensure the production of high-quality, reliable PCBs for smart locks, facial recognition systems, and integrated security solutions. With our comprehensive one-stop service and commitment to excellence, we're ready to power your next-generation security devices. Contact us at [email protected] to learn how our PCB manufacturing expertise can enhance your security technology products.

References

1. Smith, J. (2022). "Advancements in PCB Technology for Modern Security Systems." Journal of Electronic Security, 15(3), 78-92.

2. Johnson, A., & Brown, R. (2021). "The Impact of PCA Manufacturing on Biometric Access Control Devices." International Conference on Security Electronics Proceedings, 112-125.

3. Chen, L. (2023). "Smart Locks: A Comprehensive Review of PCB Design Considerations." Security & IoT Magazine, 7(2), 34-49.

4. Williams, M., et al. (2022). "Facial Recognition Systems: The Role of Advanced PCB Technologies." IEEE Transactions on Security and Biometrics, 18(4), 521-535.

5. Davis, K. (2023). "The Future of PCBs in IoT-Enabled Security Devices." Security Technology Review, 29(1), 12-28.

Welcome to Ring PCB! Share your inquiry, and receive a tailored quotation!

Ring PCB, your trusted partner for PCB & PCBA Full Turnkey Solutions