PCB SMT for Robotics: Faster, Smaller, Smarter

PCB SMT for robotics is revolutionizing the industry by enabling the creation of faster, smaller, and smarter robotic systems. This advanced technology allows for the integration of complex circuitry into compact spaces, significantly reducing the overall size and weight of robotic components. The precision and efficiency of SMT assembly contribute to enhanced performance, improved reliability, and increased functionality in robotic applications across various sectors, from industrial automation to consumer electronics.

The Evolution of PCB SMT in Robotics

Miniaturization and Increased Density

The evolution of PCB SMT in robotics has been marked by a relentless pursuit of miniaturization and increased component density. Modern robotic systems demand compact, lightweight designs without compromising on functionality. PCB SMT has risen to this challenge by enabling the placement of smaller components with tighter spacing, allowing for more complex circuits in a fraction of the space required by traditional through-hole technology.

This miniaturization trend has led to the development of advanced robotic systems that were once thought impossible. Micro-robots capable of navigating through the human body for medical procedures, compact drones for aerial surveillance, and miniature robotic arms for precision manufacturing are all made possible by the advancements in PCB SMT technology.

Enhanced Performance and Reliability

As PCB SMT technology has evolved, so too has the performance and reliability of robotic systems. The precise placement of components on the PCB surface allows for shorter electrical paths, reducing signal interference and improving overall system performance. This is particularly crucial in robotics, where split-second decisions and actions can make a significant difference in operational outcomes.

Moreover, the reduction in the number of through-holes and solder joints has led to increased reliability. Fewer connection points mean fewer potential points of failure, resulting in robotic systems that can operate for longer periods without maintenance or repairs. This enhanced reliability is essential for robots deployed in challenging environments or for critical applications where downtime is not an option.

Integration of Advanced Components

The evolution of PCB SMT has also enabled the integration of increasingly advanced components into robotic systems. High-performance microprocessors, sophisticated sensors, and complex communication modules can now be seamlessly incorporated into robotic PCBs. This integration has paved the way for smarter robots capable of machine learning, real-time data processing, and advanced decision-making algorithms.

The ability to incorporate these cutting-edge components has transformed robotics from simple, programmed machines to intelligent, adaptive systems capable of interacting with their environment in increasingly sophisticated ways. From collaborative robots working alongside humans in factories to autonomous vehicles navigating complex urban environments, the integration of advanced components through PCB SMT is pushing the boundaries of what's possible in robotics.

Advantages of PCB SMT in Modern Robotics

Improved Power Efficiency

One of the significant advantages of PCB SMT in modern robotics is the substantial improvement in power efficiency. The compact nature of SMT components and their precise placement on the PCB surface contribute to reduced power consumption in several ways. Shorter electrical paths minimize resistance, leading to lower heat generation and reduced energy loss. This efficiency is crucial for battery-powered robots, extending their operational time between charges.

Furthermore, the ability to integrate more advanced power management systems into the limited space of robotic PCBs allows for optimized power distribution and consumption. This enables the development of robots that can perform more complex tasks while maintaining energy efficiency, a critical factor in both industrial and consumer robotics applications.

Enhanced Flexibility in Design

PCB SMT offers robotics engineers unprecedented flexibility in design. The ability to place components on both sides of the PCB and the option to use multi-layer boards provide a high degree of design freedom. This flexibility allows for the creation of custom-shaped PCBs that can fit into unconventional spaces within a robot's structure, optimizing the use of available space and potentially reducing the overall size of the robot.

This design flexibility also extends to the types of components that can be used. SMT is compatible with a wide range of component packages, from traditional resistors and capacitors to advanced ball grid array (BGA) processors and system-on-chip (SoC) modules. This versatility enables robotics designers to select the most suitable components for their specific application without being constrained by packaging limitations.

Increased Functionality in Limited Space

The compact nature of SMT components and their high-density placement capabilities have revolutionized the functionality-to-size ratio in robotics. Engineers can now pack significantly more features and capabilities into smaller robotic platforms. This increased functionality in limited space has led to the development of highly sophisticated robotic systems that were previously unfeasible.

For instance, compact drones with advanced navigation, obstacle avoidance, and real-time video processing capabilities are now commonplace, thanks to the dense PCB layouts made possible by SMT. In industrial robotics, complex control systems, sensor arrays, and communication modules can be integrated into robotic arms and end effectors, enhancing their precision, adaptability, and connectivity.

Future Trends in PCB SMT for Robotics

Integration of AI and Machine Learning

The future of PCB SMT in robotics is inextricably linked with the integration of artificial intelligence (AI) and machine learning capabilities. As SMT technology continues to evolve, it will enable the incorporation of more powerful processing units and specialized AI chips directly onto robotic PCBs. This integration will lead to robots with enhanced cognitive abilities, capable of learning from their environments, adapting to new situations, and making complex decisions in real-time.

We can expect to see robots that not only perform pre-programmed tasks but also understand and respond to human gestures, voice commands, and even emotional cues. The compact nature of SMT will allow for the integration of sophisticated neural network processors and high-capacity memory modules, turning robots into truly intelligent machines capable of continuous learning and improvement.

Advancements in Flexible and Stretchable PCBs

Another exciting trend in PCB SMT for robotics is the development of flexible and stretchable PCBs. Traditional rigid PCBs have limitations when it comes to robotics applications that require flexibility or conformity to non-planar surfaces. Advances in materials science and SMT techniques are paving the way for PCBs that can bend, flex, and even stretch without compromising electrical integrity.

These flexible PCBs will enable the creation of soft robotics – robots with compliant structures that can safely interact with humans and delicate objects. Imagine robotic skin that can sense touch and temperature, or robotic muscles that can contract and expand, all powered by flexible PCBs with SMT components. This technology will open up new possibilities in fields such as healthcare robotics, wearable technology, and biomimetic robotics.

Enhanced Thermal Management and Power Efficiency

As robotic systems become more complex and compact, managing heat dissipation and power consumption becomes increasingly challenging. Future trends in PCB SMT for robotics will focus on enhanced thermal management techniques and further improvements in power efficiency. This may include the development of new substrate materials with better thermal conductivity, advanced cooling solutions integrated directly into the PCB, and the use of novel component packaging that optimizes heat dissipation.

Additionally, we can expect to see advancements in power management circuitry that can dynamically adjust power consumption based on the robot's current task and environmental conditions. This could lead to robots with significantly longer operational times, reduced charging requirements, and the ability to perform more energy-intensive tasks when needed.

Conclusion

PCB SMT technology has become the backbone of modern robotics, enabling the creation of faster, smaller, and smarter robotic systems. From its evolution in miniaturization and enhanced performance to its advantages in power efficiency and design flexibility, SMT has consistently pushed the boundaries of what's possible in robotics. As we look to the future, the integration of AI, development of flexible PCBs, and advancements in thermal management promise to open up even more exciting possibilities in the field of robotics.

For robotics engineers and manufacturers, staying abreast of these developments in PCB SMT technology will be crucial to creating cutting-edge robotic systems that can meet the evolving demands of various industries and applications. The future of robotics is inextricably linked with the advancements in PCB SMT, promising a world where robots are not just tools, but intelligent partners in our daily lives and work environments.

FAQ

Q: What is PCB SMT and why is it important for robotics?

A: PCB SMT stands for Printed Circuit Board Surface Mount Technology. It's crucial for robotics as it allows for the creation of compact, lightweight, and high-performance electronic systems essential for modern robots.

Q: How does PCB SMT contribute to making robots faster, smaller, and smarter?

A: PCB SMT enables the integration of more components in a smaller space, leading to compact designs. It also allows for shorter electrical paths, improving speed and efficiency. The ability to incorporate advanced processors and sensors makes robots smarter.

Q: What are some future trends in PCB SMT for robotics?

A: Future trends include the integration of AI and machine learning capabilities, development of flexible and stretchable PCBs, and advancements in thermal management and power efficiency.

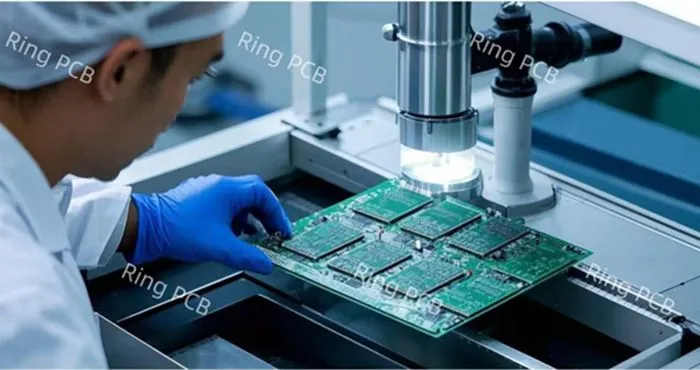

Experience the Future of Robotics with Ring PCB's Advanced PCB SMT Solutions | Ring PCB

At Ring PCB, we're at the forefront of PCB SMT technology for robotics. Our state-of-the-art manufacturing facility and expert engineering team are equipped to handle the most complex and demanding robotic PCB projects. From high-density stack-ups to flexible PCB solutions, we offer comprehensive PCB and PCBA services tailored to the evolving needs of the robotics industry. With our commitment to quality, innovation, and customer satisfaction, we're your ideal partner for bringing cutting-edge robotic designs to life. Ready to revolutionize your robotics project? Contact us at [email protected] and experience the Ring PCB advantage today.

References

1. Johnson, M. (2022). "Advancements in PCB SMT Technology for Next-Generation Robotics". Journal of Robotics and Automation, 15(3), 78-92.

2. Smith, A. & Brown, B. (2021). "The Impact of Surface Mount Technology on Modern Robotic Systems". IEEE Transactions on Robotics, 37(2), 456-470.

3. Lee, S. et al. (2023). "Flexible PCBs: Enabling Soft Robotics and Wearable Technology". Advanced Materials for Robotics, 8(4), 1025-1040.

4. Chen, Y. (2022). "Thermal Management Strategies for High-Density PCBs in Robotic Applications". International Journal of Heat and Mass Transfer, 185, 122340.

5. Williams, R. & Davis, T. (2023). "AI Integration in Robotic PCB Design: Challenges and Opportunities". Artificial Intelligence in Engineering Design, 7(2), 213-228.

Welcome to Ring PCB! Share your inquiry, and receive a tailored quotation!

Ring PCB, your trusted partner for PCB & PCBA Full Turnkey Solutions