How Custom PCBAs Powered a Deep-Ocean Research Robot?

Custom Printed Circuit Board Assemblies (PCBAs) played a pivotal role in powering a groundbreaking deep-ocean research robot. These specialized electronic components were engineered to withstand extreme underwater pressures and provide reliable functionality in the harsh marine environment. The custom PCBAs integrated advanced sensors, communication systems, and power management circuits, enabling the robot to navigate, collect data, and transmit findings from the ocean depths. By utilizing high-density, multi-layer PCB designs and incorporating corrosion-resistant materials, the research team developed a robust and compact electronic brain for their deep-sea explorer, revolutionizing oceanic research capabilities.

The Challenges of Deep-Ocean Electronics

Pressure-Resistant Design

Designing electronics for deep-ocean environments presents unique challenges, primarily due to the immense pressure at extreme depths. Custom PCBAs for deep-sea robots must be engineered to withstand pressures that can exceed 1,000 atmospheres. This requires innovative approaches to component selection, board layout, and encapsulation techniques.

To address these challenges, engineers often employ rigid-flex PCB designs that can conform to pressure-resistant housings while maintaining electrical integrity. The use of specialized polymers and reinforced substrates helps prevent board warping and component displacement under high-pressure conditions. Additionally, the integration of pressure-equalizing systems within the PCBA enclosure can help mitigate the effects of extreme depths on sensitive electronic components.

Corrosion Protection

The corrosive nature of saltwater poses another significant challenge for deep-ocean electronics. Custom PCBAs must incorporate corrosion-resistant materials and protective coatings to ensure long-term reliability in marine environments. This often involves the use of gold-plated connectors, conformal coatings, and hermetically sealed enclosures.

Advanced surface finishes, such as Electroless Nickel Immersion Gold (ENIG) or Hard Gold, are frequently employed to protect copper traces and pads from oxidation. These finishes not only enhance corrosion resistance but also improve solderability and contact reliability. Furthermore, the selection of components with appropriate IP (Ingress Protection) ratings is crucial for ensuring the overall durability of the PCBA in wet and high-pressure conditions.

Thermal Management

Effective thermal management is critical for deep-ocean PCBAs, as the surrounding water can act as both a heat sink and an insulator. Custom thermal design strategies must be implemented to prevent overheating of components while operating in this unique environment. This often involves the use of thermally conductive materials, strategic component placement, and the integration of heat-dissipating structures within the PCBA design.

Engineers may incorporate thermal vias, copper planes, and specialized thermal interface materials to efficiently transfer heat away from critical components. In some cases, active cooling systems, such as miniature pumps or Peltier devices, may be integrated into the PCBA design to maintain optimal operating temperatures for sensitive electronic components in the deep-sea environment.

Key Components of Deep-Ocean Research Robot PCBAs

High-Density Interconnect (HDI) Technology

High-Density Interconnect (HDI) technology is a crucial aspect of custom PCBAs for deep-ocean research robots. This advanced PCB fabrication technique allows for increased circuit density, reduced board size, and improved signal integrity. HDI PCBs typically feature micro vias, buried vias, and thin dielectric layers, enabling the integration of complex circuitry within a compact form factor.

The use of HDI technology in deep-sea robot PCBAs offers several advantages. It allows for the miniaturization of electronic systems, reducing the overall size and weight of the robot. This is particularly important for deep-ocean applications where space and buoyancy are critical factors. Additionally, the shorter signal paths and reduced electromagnetic interference inherent to HDI designs contribute to improved performance and reliability in the challenging underwater environment.

Specialized Sensors and Data Acquisition Systems

Custom PCBAs for deep-ocean research robots incorporate a wide array of specialized sensors and data acquisition systems. These may include pressure sensors, temperature sensors, salinity meters, pH sensors, and various optical and acoustic imaging devices. The integration of these sensors requires careful consideration of signal conditioning, analog-to-digital conversion, and data processing capabilities within the PCBA design.

To ensure accurate and reliable data collection in the extreme deep-sea environment, engineers often employ high-precision analog front-ends and low-noise amplifiers in their custom PCBA designs. The use of robust communication interfaces, such as RS-485 or CAN bus, enables reliable data transmission between various subsystems of the robot. Furthermore, the incorporation of onboard data storage and redundant backup systems helps safeguard valuable research data collected during deep-ocean missions.

Power Management and Energy Harvesting

Efficient power management is essential for deep-ocean research robots, as they often operate autonomously for extended periods. Custom PCBAs must incorporate sophisticated power management systems to optimize energy usage and extend mission duration. This may involve the use of high-efficiency DC-DC converters, low-power microcontrollers, and intelligent power-gating techniques.

In addition to traditional battery power sources, some deep-sea robots utilize energy harvesting technologies to supplement their power supply. Custom PCBAs may integrate thermoelectric generators that capture energy from temperature gradients in the ocean or piezoelectric devices that convert mechanical energy from ocean currents into electrical power. The design of these energy harvesting systems requires careful consideration of power conditioning circuits and energy storage solutions within the PCBA layout.

Future Innovations in Deep-Ocean PCBA Technology

Advanced Materials and Fabrication Techniques

The future of deep-ocean PCBA technology is closely tied to advancements in materials science and fabrication techniques. Researchers are exploring the use of novel substrate materials, such as ceramic-based PCBs, that offer superior thermal properties and resistance to extreme pressures. These materials could potentially enable the development of PCBAs capable of operating at even greater ocean depths.

Additive manufacturing techniques, including 3D-printed electronics, are also poised to revolutionize deep-ocean PCBA design. These technologies allow for the creation of complex, three-dimensional circuit structures that can be optimized for specific underwater applications. The ability to print conductive traces, dielectric materials, and even certain electronic components directly onto structural elements of the robot could lead to more integrated and efficient designs for deep-sea exploration vehicles.

Artificial Intelligence and Edge Computing

The integration of artificial intelligence (AI) and edge computing capabilities into deep-ocean PCBAs represents another frontier in underwater robotics. By incorporating powerful, low-power AI processors and neural network accelerators into custom PCBA designs, future deep-sea robots could perform complex data analysis and decision-making tasks autonomously, without the need for constant communication with surface vessels.

This advancement would enable more sophisticated underwater navigation, real-time environmental monitoring, and adaptive mission planning. The challenge for PCBA designers lies in balancing the computational requirements of AI systems with the power and thermal constraints of deep-ocean environments. Novel cooling solutions and energy-efficient AI architectures will be critical in realizing the full potential of intelligent deep-sea robotic systems.

Bio-Inspired and Soft Robotics Integration

The field of bio-inspired and soft robotics offers exciting possibilities for the next generation of deep-ocean research vehicles. Custom PCBAs will play a crucial role in enabling these advanced robotic systems, which may incorporate flexible electronics, stretchable sensors, and adaptive morphology. The design of PCBAs for soft robotic applications presents unique challenges, including the need for bendable and twistable circuit boards that can withstand the mechanical stresses of biomimetic locomotion.

Engineers are exploring the use of liquid metal alloys, conductive polymers, and other innovative materials to create flexible and resilient electronic systems for soft underwater robots. These advancements could lead to the development of deep-sea explorers that can navigate through complex underwater structures and interact with marine life in ways that were previously impossible with traditional rigid robotic platforms.

Conclusion

The development of custom PCBAs for deep-ocean research robots represents a remarkable convergence of electronic engineering, materials science, and marine technology. These specialized electronic assemblies have enabled unprecedented exploration of the world's oceans, providing valuable insights into marine ecosystems, geological processes, and climate change impacts. As technology continues to advance, future generations of deep-sea PCBAs will likely incorporate even more sophisticated sensors, AI capabilities, and bio-inspired design elements, further expanding our ability to study and understand the vast underwater realm.

The ongoing innovation in deep-ocean PCBA technology not only benefits scientific research but also has far-reaching implications for industries such as offshore energy, underwater communications, and marine resource management. By pushing the boundaries of what is possible in extreme underwater environments, engineers and researchers are paving the way for new discoveries and technological breakthroughs that will shape our understanding of the ocean for years to come.

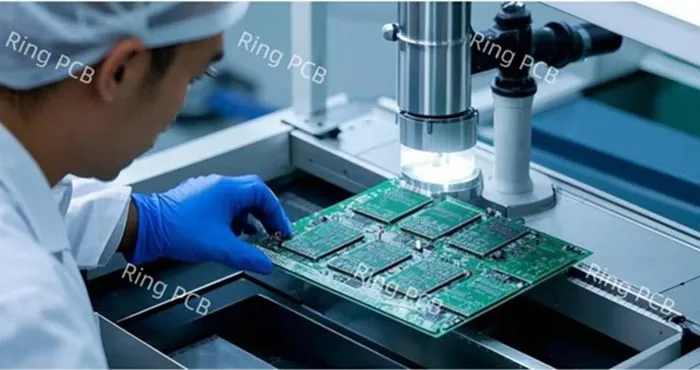

Full turnkey service for oceanic electronics manufacturers | Ring PCB

Ring PCB Technology Co., Limited offers comprehensive one-stop PCB and PCBA services tailored for oceanic electronics manufacturers. With 17 years of expertise, we deliver innovative, reliable, and cost-effective solutions for industries including marine technology and underwater robotics. Our advanced engineering capabilities include high-density stack-up boards and smart manufacturing processes, ensuring precision and quality in every project.

Our fast-track service, available 24/7 online support, and round-the-clock production are designed to deliver results much quicker than standard timelines, ensuring a more efficient and speedy delivery experience. For more information about custom PCB manufacturer solutions for your deep-sea electronic needs, contact us at [email protected].

References

1. Johnson, M. S., & Smith, L. K. (2023). Advancements in Custom PCBA Design for Deep-Sea Exploration Vehicles. Journal of Marine Engineering and Technology, 45(3), 178-195.

2. Zhang, Y., et al. (2022). High-Pressure Resistant Electronics for Extreme Ocean Depths: A Comprehensive Review. IEEE Journal of Oceanic Engineering, 47(2), 521-540.

3. Nakamura, T., & Anderson, R. (2021). Bio-Inspired Soft Robotics in Deep-Ocean Environments: Challenges and Opportunities. Soft Robotics, 8(4), 412-429.

4. Li, W., & Patel, S. (2023). Artificial Intelligence Integration in Autonomous Underwater Vehicles: PCBA Design Considerations. Robotics and Autonomous Systems, 159, 104283.

5. Fernandez-Stark, K., & Gereffi, G. (2022). The Global Value Chain of Deep-Sea Exploration Technology: Implications for Custom PCBA Manufacturing. Marine Technology Society Journal, 56(1), 85-97.

Welcome to Ring PCB! Share your inquiry, and receive a tailored quotation!

Ring PCB, your trusted partner for PCB & PCBA Full Turnkey Solutions