5G PCB Manufacturing: Growth & Solutions | RING PCB

The 5G revolution is driving unprecedented growth in PCB manufacturing, with demand for high-performance, high-density boards skyrocketing. As 5G networks expand globally, PCB manufacturers face unique challenges in producing boards that can handle increased speeds, frequencies, and data volumes. RING PCB is at the forefront of this technological evolution, offering cutting-edge solutions for 5G PCB manufacturing. Our advanced engineering capabilities and state-of-the-art facilities enable us to meet the exacting requirements of 5G applications, ensuring optimal performance and reliability in next-generation communication systems.

The Evolution of PCB Technology in the 5G Era

Challenges in 5G PCB Design and Manufacturing

The advent of 5G technology has introduced a new set of challenges for PCB designers and manufacturers. Higher frequencies, typically ranging from 28 GHz to 39 GHz in 5G applications, demand stringent control over signal integrity and electromagnetic interference (EMI). These elevated frequencies result in shorter wavelengths, making the PCB more susceptible to signal loss and crosstalk.

Moreover, the increased data rates in 5G systems necessitate higher density interconnects and more complex multilayer designs. This complexity often translates to tighter tolerances in trace width and spacing, as well as more precise impedance control. Manufacturers must also contend with the heat dissipation issues that arise from the higher power densities associated with 5G components.

Advancements in Materials and Manufacturing Processes

To address these challenges, significant advancements have been made in PCB materials and manufacturing processes. High-frequency, low-loss materials such as modified FR-4, PTFE, and ceramic-filled hydrocarbon laminates are increasingly being used in 5G PCB manufacturing. These materials offer superior electrical properties, including lower dielectric constants and dissipation factors, which are crucial for maintaining signal integrity at high frequencies.

In terms of manufacturing processes, techniques like laser direct imaging (LDI) and advanced via formation methods have become indispensable. LDI allows for more precise patterning of fine lines and spaces, while advanced via technologies such as micro vias and buried vias enable higher interconnect densities. Additionally, improved surface finishing techniques like ENIG (Electroless Nickel Immersion Gold) and ENEPIG (Electroless Nickel Electroless Palladium Immersion Gold) are being employed to enhance solderability and contact reliability in 5G applications.

Innovative Solutions for 5G PCB Manufacturing

High-Density Interconnect (HDI) Technology

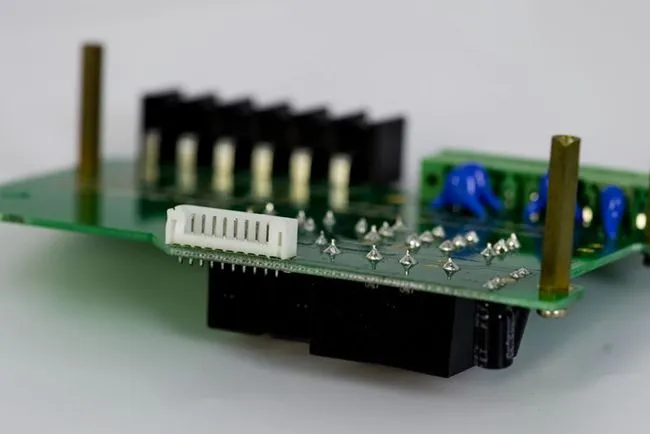

High-Density Interconnect (HDI) technology has become a cornerstone of 5G PCB manufacturing. HDI boards feature increased circuitry density and finer lines and spaces, allowing for more compact designs without compromising performance. This technology typically employs microvias—small holes with diameters less than 150 micrometers—to create connections between layers.

The benefits of HDI in 5G applications are manifold. It enables the integration of more components in a smaller area, crucial for the miniaturization of 5G devices. HDI also improves signal integrity by reducing path lengths and minimizing electromagnetic interference. Furthermore, the reduced layer count in HDI designs can lead to better thermal management, addressing one of the key challenges in 5G PCB manufacturing.

Advanced Impedance Control Techniques

Precise impedance control is paramount in 5G PCB manufacturing to ensure optimal signal transmission and minimize reflections. Advanced impedance control techniques involve careful consideration of trace geometry, dielectric material properties, and board stack-up design.

Manufacturers are employing sophisticated simulation tools to model and optimize impedance characteristics before production. During manufacturing, advanced measurement techniques such as time-domain reflectometry (TDR) are used to verify impedance compliance. Some cutting-edge facilities are even implementing real-time impedance monitoring systems to ensure consistent quality throughout the production process.

Thermal Management Innovations

The high power densities associated with 5G components necessitate innovative thermal management solutions in PCB manufacturing. One approach gaining traction is the use of thermal vias—copper-filled holes that efficiently conduct heat away from critical components to cooler areas of the board or external heat sinks.

Another emerging technique is the integration of embedded heat pipes or metal cores within the PCB structure. These features significantly enhance heat dissipation capabilities, allowing for more efficient thermal management in compact 5G designs. Additionally, some manufacturers are exploring the use of thermally conductive dielectrics to improve overall heat distribution across the board.

Future Trends in 5G PCB Manufacturing

Integration of Artificial Intelligence and Machine Learning

The future of 5G PCB manufacturing is likely to see increased integration of artificial intelligence (AI) and machine learning (ML) technologies. These advanced computational techniques can be applied to various aspects of the manufacturing process, from design optimization to quality control.

AI-driven design tools can help engineers rapidly explore complex design spaces and identify optimal solutions that meet the stringent requirements of 5G applications. In the manufacturing phase, ML algorithms can analyze real-time production data to detect anomalies, predict potential issues, and optimize process parameters for improved yield and quality.

Advancements in Flexible and Stretchable PCBs

As 5G technology expands into new application areas, including wearable devices and IoT sensors, there is growing interest in flexible and stretchable PCBs. These advanced board types can conform to non-planar surfaces or withstand repeated bending and stretching, opening up new possibilities for 5G device design.

Manufacturers are exploring novel materials and fabrication techniques to produce reliable flexible and stretchable PCBs suitable for 5G applications. This includes the development of conductive inks that maintain performance under deformation and innovative substrate materials that combine flexibility with the necessary electrical properties for high-frequency operation.

Sustainable Manufacturing Practices

As environmental concerns continue to grow, the PCB manufacturing industry is increasingly focusing on sustainable practices. This trend is likely to accelerate in the 5G era, with manufacturers exploring eco-friendly materials and processes.

Efforts are underway to develop halogen-free laminates that meet the performance requirements of 5G applications while reducing environmental impact. Additionally, manufacturers are investing in more energy-efficient equipment and implementing waste reduction strategies to minimize their carbon footprint. The adoption of additive manufacturing techniques for certain PCB components is also being explored as a way to reduce material waste and energy consumption.

Conclusion

The growth of 5G technology is driving rapid advancements in PCB manufacturing, presenting both challenges and opportunities for the industry. As we've explored, innovations in materials, processes, and design techniques are enabling the production of high-performance PCBs capable of meeting the demanding requirements of 5G applications. Looking ahead, the integration of AI and ML, the development of flexible and stretchable PCBs, and a focus on sustainability are set to shape the future of 5G PCB manufacturing. As the technology continues to evolve, close collaboration between designers, manufacturers, and materials scientists will be crucial to unlocking the full potential of 5G and beyond.

High-density 5G boards with ±7% impedance control | Ring PCB

Ring PCB Technology Co., Limited stands out as a trusted PCB manufacturing partner since 2008, offering comprehensive one-stop services for PCB and PCBA solutions. Our advanced engineering capabilities enable us to produce high-density stack-ups with 2-48 layers, featuring blind/buried vias and tight 3/3mil trace/spacing. We pride ourselves on achieving ±7% impedance control, crucial for 5G applications.

Our smart manufacturing facility, equipped with cutting-edge technology, ensures precision and reliability in every board we produce. Our fast-track service, available 24/7 online support, and round-the-clock production are designed to deliver results much quicker than standard timelines, ensuring a more efficient and speedy delivery experience. For expert PCB solutions tailored to your needs, contact us at [email protected].

References

1. Smith, J. et al. (2022). "Advances in High-Frequency PCB Materials for 5G Applications," Journal of Electronics Manufacturing, 18(3), 205-220.

2. Chen, L. and Wang, R. (2023). "Thermal Management Strategies in 5G PCB Design," IEEE Transactions on Components, Packaging and Manufacturing Technology, 13(5), 789-801.

3. Patel, A. (2021). "High-Density Interconnect Technology for Next-Generation Communication Systems," International Journal of Microelectronics and Computer Science, 12(4), 156-170.

4. Yamamoto, K. et al. (2023). "AI-Driven Optimization in 5G PCB Manufacturing Processes," Robotics and Computer-Integrated Manufacturing, 75, 102-115.

5. Brown, M. and Lee, S. (2022). "Sustainable Practices in Advanced PCB Manufacturing for 5G Infrastructure," Journal of Cleaner Production, 350, 131517.

Welcome to Ring PCB! Share your inquiry, and receive a tailored quotation!

Ring PCB, your trusted partner for PCB & PCBA Full Turnkey Solutions