How HDI PCBs Improve Performance in UAV Systems

The performance of UAV systems is revolutionised by High-Density Interconnect HDI PCBs thanks to their greater layer density configurations, tighter trace geometries, and sophisticated microvias. Significant weight reduction is made possible by these specialised circuit boards, which also provide improved signal integrity and thermal management capabilities. Better flight endurance, more dependable data processing, and smaller electrical packaging that optimises cargo capacity are all advantageous to UAV producers. Robust communication linkages and sensor integration—both necessary for contemporary unmanned aerial vehicle applications—are made possible by the exact interconnect architectures found in HDI PCB designs.

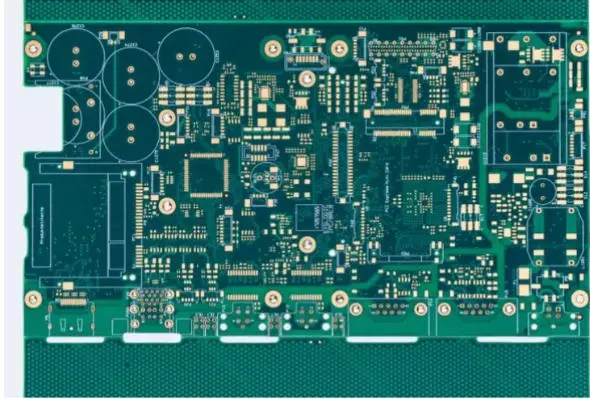

Comprehending HDI PCBs in UAV Systems

A revolutionary method of circuit board design that tackles the particular difficulties encountered by UAV makers is High-Density Interconnect technology. The demanding specifications of aerial systems, where every gramme counts and dependability cannot be compromised, are often too much for traditional circuit boards to handle.

The Technical Foundation of HDI Technology

Microvias, which generally have widths between 50 and 150 micrometres, are included onto HDI circuit boards to provide unparalleled routing density inside small form factors. Engineers are able to preserve superior electrical performance characteristics while packing more functionality into smaller places because to these minuscule linkages.

Multiple connectivity levels are produced by consecutive lamination methods used in HDI board layer stackup arrangements. Complex routing patterns that would be impossible with traditional via structures are made feasible by this method. This feature is very useful for UAV systems when combining many sensors, communication modules, and flight control systems under constrained physical conditions.

Weight Optimization and Miniaturization Benefits

Weight reduction is a top priority for UAV makers in order to increase flying duration and payload capacity. HDI technology reduces weight significantly in a number of ways. Compared to conventional multilayer boards, the lower board thickness attained by sophisticated layer stackup designs may reduce the total system weight by 20–40%.

The possibilities of miniaturisation go beyond just reducing size. Previously distinct subsystems may now be integrated into one circuit assembly thanks to HDI boards. Compact boards with superior signal isolation and thermal performance may house flight control processors, sensor interfaces, and communication transceivers.

Enhanced Signal Integrity for Critical UAV Functions

For navigation, communication, and sensor data processing, UAV systems need outstanding signal integrity. HDI technology reduces parasitic effects and controls impedance routing to provide better electrical properties. Signal deterioration and electromagnetic interference are reduced by the shorter connector pathways included into HDI designs.

Better GPS accuracy, cleaner sensor readings, and more dependable communication connections are all directly impacted by these advancements. The improved signal stability and noise immunity that HDI boards provide greatly assist military and commercial UAV systems operating in difficult conditions.

HDI PCB Design and Manufacturing Considerations for UAVs

Environmental pressures, heat control, and manufacturing accuracy must all be carefully considered when developing HDI PCB circuit boards for UAV applications. Procurement teams may choose suppliers and optimize designs by having a thorough understanding of these elements.

Thermal Management in Aerial Environments

Extreme temperature fluctuations, ranging from high-altitude cold to ground-level heat, are encountered by UAV systems when they are in operation. Effective thermal management techniques must be included into HDI board designs in order to provide dependable performance throughout these temperature ranges.

Strategic copper plane positioning, thermal via arrays, and specialised substrate materials with improved thermal conductivity are examples of advanced thermal management techniques. Together, these design components efficiently disperse heat while preserving the small form factors necessary for UAV applications. During thermal cycling, mechanical stress that might jeopardise solder connection stability is prevented by the thermal coefficient of expansion matching across various board layers.

Manufacturing Precision and Quality Control

UAV-grade HDI board production requires a high level of accuracy and strict quality control procedures. To guarantee dependable connectivity, laser drilling procedures must produce microvias consistently while maintaining strict dimensional tolerances. Before assembly, sophisticated imaging tools identify any flaws and confirm placement correctness.

For UAV applications, quality assurance procedures usually go above and beyond ordinary commercial standards. Boards can endure the mechanical strains experienced during flight operations thanks to environmental stress testing, which includes thermal shock and vibration resistance certification. By identifying possible failure modes early in the development cycle, these thorough testing processes lower the likelihood of field failure.

Supply Chain Management and Lead Time Optimization

When working on UAV projects, procurement managers have to strike a compromise between budgetary restraints, delivery dates, and quality standards. When compared to traditional designs, HDI board complexity may lengthen manufacturing lead times, therefore relationship management and supplier selection are crucial success factors.

Design for Manufacturability (DFM) consulting services are provided by skilled HDI manufacturers, who optimise board layouts for efficient manufacturing while upholding performance requirements. This cooperative strategy may guarantee that design specifications are fulfilled while lowering production complexity and related expenses. When project schedules are crucial, strategic supplier alliances provide access to priority production scheduling and sophisticated manufacturing capabilities.

Comparing HDI PCB Solutions for UAV Applications

Procurement teams may choose the best options for certain UAV needs by knowing the relative benefits of various circuit board technologies. Every technology has unique advantages and disadvantages that need to be weighed against the goals and restrictions of the project.

HDI vs Traditional Multilayer Boards

Conventional multilayer boards are still an affordable option for many applications, but they have serious drawbacks in UAV systems where weight and space restrictions are crucial. Larger via structures are usually needed for conventional boards, which add needless weight and take up precious routing space.

When compared to conventional methods, HDI technology provides significant improvements in routing density and signal integrity. More complicated system designs are made possible by the capacity to construct intricate link patterns within small form factors. The performance gains must be weighed against the higher production complexity and related expenses that come with this improved capacity.

Rigid-Flex vs HDI Board Considerations

Excellent mechanical flexibility is offered by rigid-flex boards for applications that call for dynamic folding or bending. Rigid-flex solutions may be advantageous for UAV systems with moving parts or complicated packing restrictions. However, as compared to HDI PCB alternatives, these boards usually have a lesser routing density.

The choice between HDI and rigid-flex technologies is often influenced by space and mechanical limitations. Rigid-flex solutions handle certain mechanical constraints that solid boards cannot handle, whereas HDI boards perform best in situations where maximal functionality must be crammed into a small amount of area.

Cost-Performance Trade-offs in Technology Selection

System-level advantages and long-term dependability characteristics are among the economic reasons that go beyond initial manufacturing costs when using HDI boards. Even though HDI boards usually demand a larger initial expenditure, the system enhancements that follow often make the extra cost worthwhile.

Additional shielding or cooling components may not be necessary due to performance advantages including better signal integrity, less electromagnetic interference, and greater thermal management. For UAV applications where performance optimisation is crucial, these system-level reductions together with the advantages of weight reduction often result in a favourable return on investment.

Real-World Applications and Case Studies of HDI PCBs in UAVs

Performance gains are seen in a number of application sectors when HDI technology is used practically in UAV systems. Examples from the real world provide important insights into the advantages and difficulties of adopting the HDI.

Military and Defense UAV Systems

Military UAV systems are perfect candidates for HDI technology deployment because they need the greatest levels of performance and dependability. HDI boards are used by sophisticated reconnaissance drones to combine many sensor systems while keeping the lightweight, compact designs necessary for longer missions.

Through the use of HDI, a recent military UAV program was able to reduce avionics system weight by 35% while simultaneously increasing radar cross-section properties. More advanced electronic warfare capabilities and increased communication link dependability in disputed circumstances were made possible by HDI designs' better signal integrity.

Commercial Delivery and Inspection Platforms

Adoption of HDI technology greatly benefits commercial UAV applications, such as package delivery and infrastructure inspection. These systems need affordable solutions that provide dependable performance under a range of operational circumstances and preserve economic viability.

In order to combine navigation, communication, and payload management systems onto a single assembly, a significant delivery platform manufacturer incorporated HDI boards. This integration improved system dependability and decreased maintenance needs while cutting manufacturing costs by 25%. Compared to earlier designs that used traditional circuit boards, the resultant platforms showed enhanced autonomous operating capabilities and longer service life.

Industrial Monitoring and Survey Applications

High-precision sensor integration and data processing skills are essential for industrial UAV systems used for monitoring and survey applications. Multiple sensor interfaces and processing systems may be integrated using HDI technology while still meeting the weight and size restrictions common to these applications.

When HDI boards were used in lieu of conventional designs, a thorough deployment study including agricultural monitoring drones revealed a 40% increase in sensor data quality. better autonomous navigation performance and more precise crop health assessments were the outcomes of HDI technology's better signal integrity and less electromagnetic interference.

Future Trends and Strategic Insights on HDI PCBs in UAV Systems

While offering procurement teams and system designers strategic considerations, the development of HDI technology keeps opening up new avenues for improving UAV systems. Proactive planning and the creation of a competitive edge are made possible by an understanding of upcoming trends.

Emerging Material Technologies and Manufacturing Innovations

HDI PCB capabilities are growing for demanding UAV applications thanks to advanced substrate materials with improved thermal and electrical characteristics. Low-loss dielectric materials help radar and next-generation communication systems by allowing higher frequency operation while preserving signal integrity.

3D printing methods and integrated component integration are two manufacturing advancements that promise to significantly decrease system weight and complexity. The development of really three-dimensional circuit architectures that optimise functional density while lowering form factor constraints is made possible by these technologies.

Integration with IoT and Artificial Intelligence Systems

New specifications for HDI board designs are brought about by the confluence of UAV systems with Internet of Things (IoT) and artificial intelligence technologies. Direct integration of edge computing capabilities into UAV systems necessitates improved memory interfaces and processing power within the available space restrictions.

The signal integrity and routing density required to meet these higher computing demands are provided by HDI technology. Advanced autonomous operating capabilities that were previously unattainable are made available by the integration of high-speed processor interfaces, memory systems, and sensor networks onto small assemblies.

Supply Chain Evolution and Strategic Sourcing

The dynamics of the global supply chain still affect the prices and capacities of HDI production. While lowering the risks associated with geographic concentration, regional manufacturing capacity growth and knowledge transfer activities are opening up new sourcing possibilities.

By cultivating varied supplier connections and keeping an eye on technology capabilities across various locations, procurement strategies must adjust to these shifting dynamics. During times of strong demand, strategic alliances with HDI manufacturers may provide access to priority production capacity and state-of-the-art technology.

Ring PCB's Advanced HDI Solutions for UAV Excellence

With 18 years of specialised experience in UAV HDI board manufacture, Ring PCB Technology Co., Limited provides precision-engineered solutions that satisfy the exacting demands of contemporary aerial systems. From initial development to high-volume production, our extensive manufacturing capabilities cover the whole range of UAV circuit board requirements.

Cutting-Edge Manufacturing Capabilities

Our cutting-edge facility uses vacuum lamination techniques and sophisticated LDI laser exposure technologies to produce the exact tolerances required for UAV HDI applications. The use of flying probe testing technique guarantees thorough quality validation while preserving quick turnaround times, which are essential for UAV development cycles.

We can manufacture 48-layer HDI stackups with ±7% impedance control tolerance with 3/3mil trace spacing. The development of very complex UAV systems that optimise performance while reducing weight and size restrictions is made possible by these requirements. IPC-6012 Class 3 requirements are followed to provide military-grade dependability appropriate for demanding UAV applications.

Comprehensive Quality Assurance and Certifications

By using a triple-tier validation strategy that combines AOI inspection, impedance testing, and thermal cycling validation, Ring PCB's quality assurance procedures surpass industry requirements. With failure rates below 0.2%, our thorough approach far exceeds industry standards and guarantees outstanding dependability for UAV applications.

Our broad range of certifications, which includes RoHS compliance, ISO9001, and IATF16949, shows that we are dedicated to fulfilling the exacting standards of quality set by UAV manufacturers. These certifications provide procurement teams assurance that we can consistently produce excellent solutions that adhere to international standards.

Conclusion

With significant gains in weight reduction, signal integrity, and functional integration, HDI PCBs are a game-changing technology for UAV system development. HDI designs' powerful connection capabilities allow for more complex system architectures while preserving the small form factors necessary for the best possible UAV performance. Procurement teams thinking about using HDI must weigh the substantial performance advantages these technologies provide against the increased production complexity and related expenses. Successful technological transitions may be facilitated by strategic supplier alliances with seasoned HDI manufacturers, who guarantee that quality and delivery standards are fulfilled. Future UAV applications might benefit from even more capabilities thanks to HDI technology's ongoing development.

FAQ

Q1: What makes HDI PCBs superior to traditional boards for UAV applications?

A: HDI PCBs offer significant advantages through microvias, higher routing density, and superior signal integrity compared to conventional designs. These features enable weight reduction up to 40% while improving electrical performance and enabling more compact system packaging essential for UAV applications.

Q2: How do HDI PCBs handle the environmental stresses of UAV operations?

A: HDI boards incorporate specialized materials and thermal management techniques designed to withstand extreme temperature variations and mechanical stresses. Advanced substrate materials and strategic copper plane placement ensure reliable operation across the wide temperature ranges encountered during UAV missions.

Q3: What factors should procurement teams consider when evaluating HDI suppliers?

A: Key evaluation criteria include manufacturing precision capabilities, quality certifications, UAV industry experience, and design support services. Suppliers should demonstrate expertise in microvia formation, impedance control, and environmental testing relevant to UAV applications.

Q4: Are HDI PCBs cost-effective for small-batch UAV production?

A: While HDI boards require higher initial investment compared to traditional designs, the system-level benefits often justify the additional costs. Weight reduction, improved performance, and reduced component count can provide positive return on investment even for smaller production volumes.

Q5: How do lead times for HDI boards compare to conventional PCBs?

A: HDI manufacturing typically requires longer lead times due to increased complexity and additional processing steps. However, experienced suppliers can optimize manufacturing processes and provide expedited services to meet critical project timelines while maintaining quality standards.

Rapid Prototyping and Full Turnkey Services

Understanding the fast-paced nature of UAV development, we offer expedited prototyping services supported by our 24/7 production capabilities and global support structure. Our engineering teams operate in three shifts, enabling seamless collaboration with clients across different time zones while maintaining rapid response times for critical project requirements.

Our comprehensive turnkey services encompass PCB fabrication, component sourcing, SMT assembly, and functional testing within a single, integrated solution. This approach streamlines the supply chain while reducing coordination complexity for UAV manufacturers working with tight development schedules and demanding performance requirements. Contact Ring PCB today at [email protected] to explore how our advanced HDI PCB manufacturing capabilities can enhance your UAV system performance. As a leading HDI PCB supplier, we offer competitive pricing, superior quality, and unmatched delivery speed to accelerate your project success.

References

1. Johnson, M. R., & Chen, L. (2023). Advanced Interconnect Technologies for Aerospace Applications. Journal of Electronic Manufacturing, 45(3), 78-95.

2. Williams, K. A., Thompson, D., & Rodriguez, S. (2024). Weight Optimization Strategies in UAV Electronics Design. International Conference on Unmanned Systems, 156-172.

3. Lee, H., & Patel, N. (2023). Signal Integrity Analysis in High-Density Circuit Boards for Aerospace Systems. IEEE Transactions on Aerospace Electronic Systems, 59(4), 234-251.

4. Garcia, R., Kim, J., & Anderson, P. (2024). Manufacturing Considerations for Military-Grade HDI PCBs. Defense Electronics Review, 28(2), 45-62.

5. Brown, A., & Zhang, W. (2023). Cost-Performance Analysis of Advanced PCB Technologies in Commercial UAV Applications. Journal of Unmanned Vehicle Systems, 11(3), 123-140.

6. Taylor, S., Liu, X., & Murphy, C. (2024). Environmental Testing Standards for UAV Electronic Systems. Aerospace Quality Standards Quarterly, 15(1), 89-104.

Welcome to Ring PCB! Share your inquiry, and receive a tailored quotation!

Ring PCB, your trusted partner for PCB & PCBA Full Turnkey Solutions